Piston type wind tunnel special gas inflation method utilizing compressed air power

A technology of special gas and compressed air, which is applied in the field of wind tunnel test, can solve the problems of low inflation efficiency, slow inflation speed, and small safety risk, and achieve the effect of high inflation efficiency, fast inflation speed and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

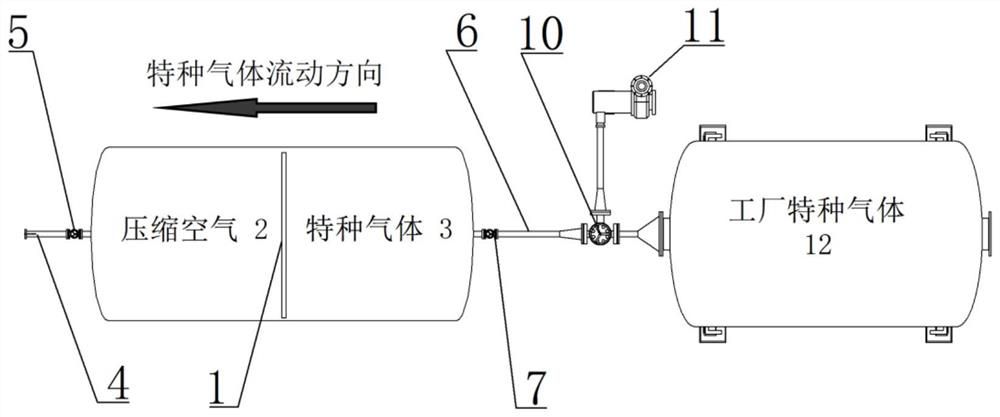

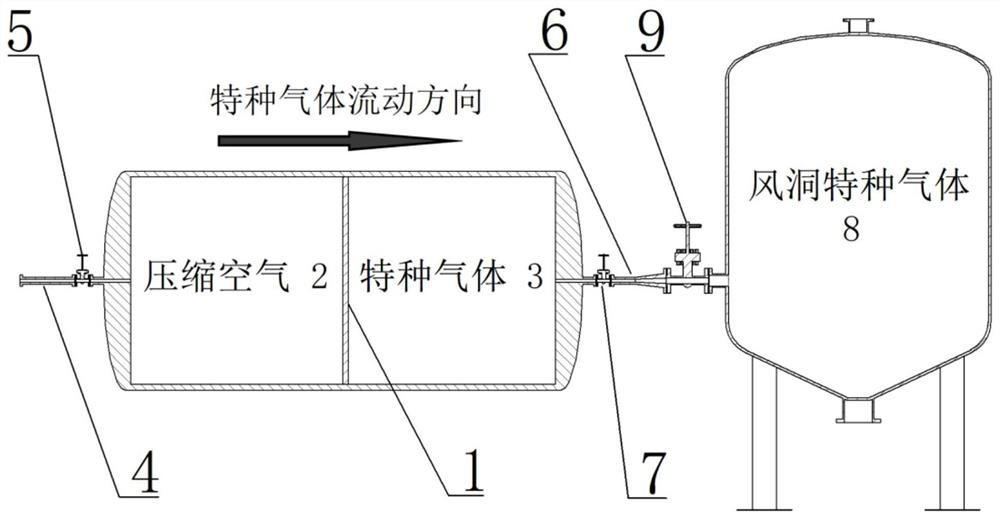

Method used

Image

Examples

Embodiment 1

[0053] The volume of the fixed gas storage tank 8 of the present embodiment is 10m3, and the volume of the piston type gas storage tank is 8m 3 , the pressure is 15MPa, and the weight is 4.7 tons. Using the 16MPa wind tunnel high-pressure gas source, the CF4 gas in the piston gas storage tank is filled to the fixed gas storage tank 8 within 10 minutes. The pressure of the fixed gas storage tank 8 is 12MPa. Under the jet flow rate of 5 kg per second, a total of 31 wind tunnel jet tests can be completed in a single 30-second period, which can meet the needs of the first-phase wind tunnel jet test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com