Distributed metal cutting chip wastewater detection device

A technology for metal cutting and waste water detection, applied to measuring devices, weighing and analyzing materials by removing certain components, can solve the problems of cumbersome operation process, small value of engine oil content, sticking, etc., and achieve cumbersome operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

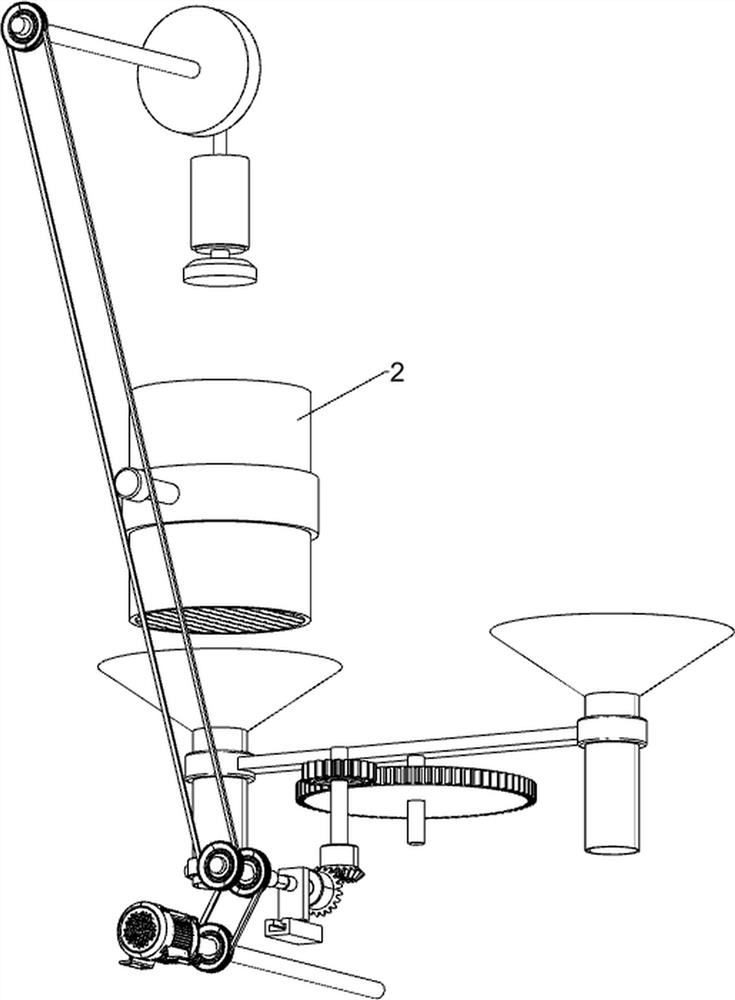

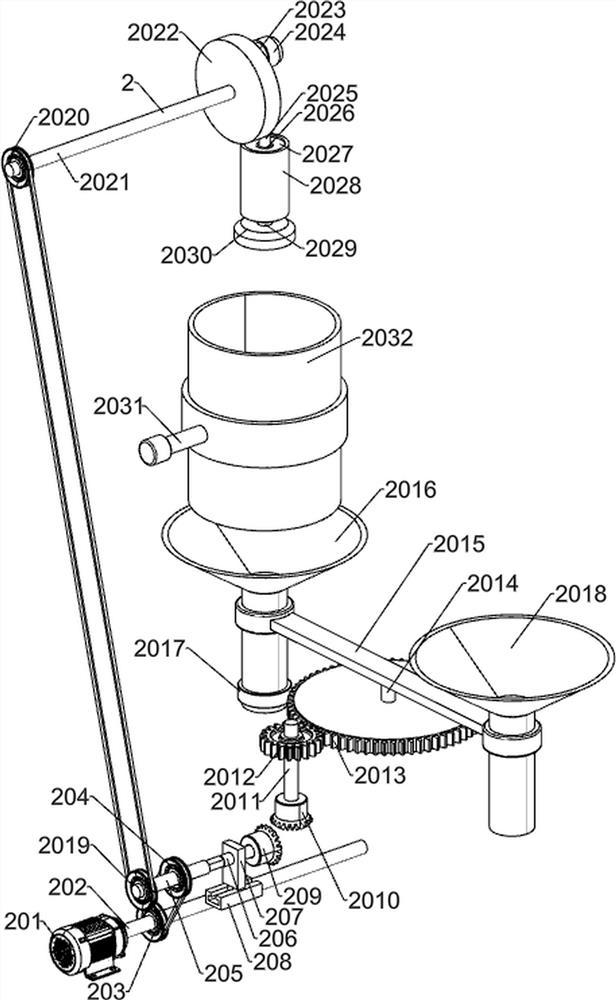

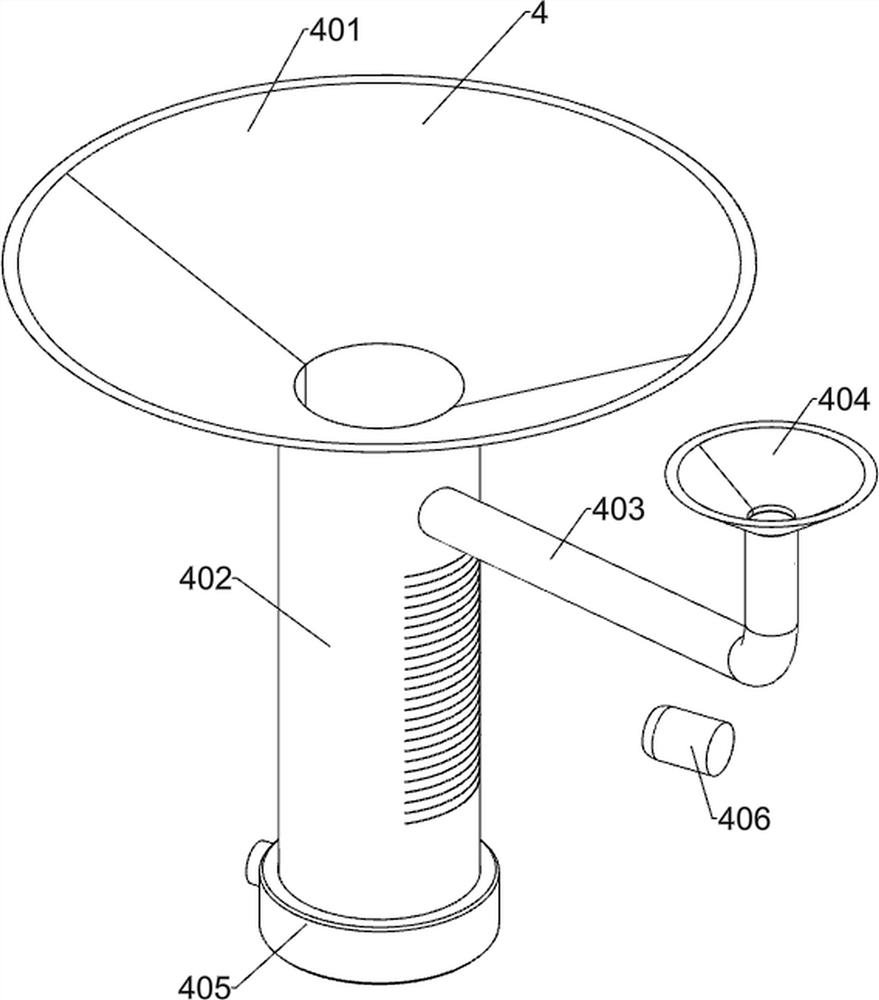

[0029] A decentralized detection device for metal cuttings waste water, such as Figure 1-9 As shown, it includes a bottom frame 1, a sub-screen assembly 2, a material distribution reprocessing assembly 3, a detection assembly 4 and a control panel 5; the bottom frame 1 is connected with the sub-screen assembly 2; The base frame 1 is connected with the detection component 4; the top of the base frame 1 is connected with the control panel 5;

[0030] Working principle: When preparing for work, place the device on a horizontal surface, turn on the power, pour the waste water of metal cuttings to be detected into the sub-screening assembly 2, and then control the control panel 5 on the bottom frame 1 to start operation, and the sub-screening Component 2 separates the metal cuttings and waste water, and transports the waste water to the detection component 4. At this time, part of the engine oil is driven by the waste water to the detection component 4, and the other part of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com