Monitoring terminal of laboratory ultrasonic biological treatment device

A monitoring terminal and biological processing technology, applied in biological testing, measuring ultrasonic/sonic/infrasonic waves, measuring devices, etc., can solve the problem of fine frequency adjustment of different objects, which consumes manpower, financial resources, and material resources, and cannot guarantee high efficiency. Frequency and other issues, to achieve the effect of reducing the space occupied by the machine body, improving the utilization rate, and intuitive and clear operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

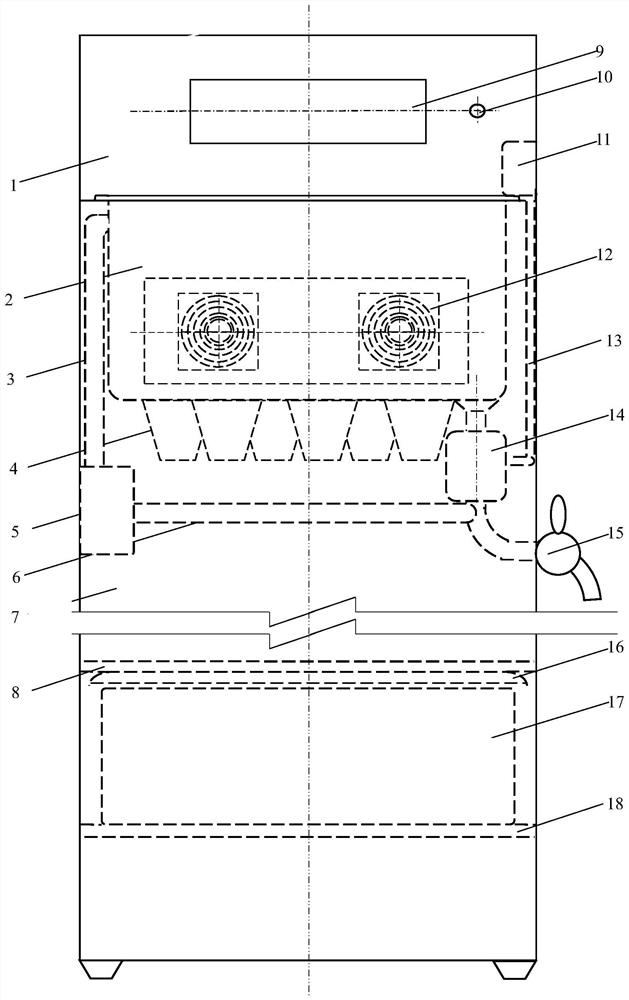

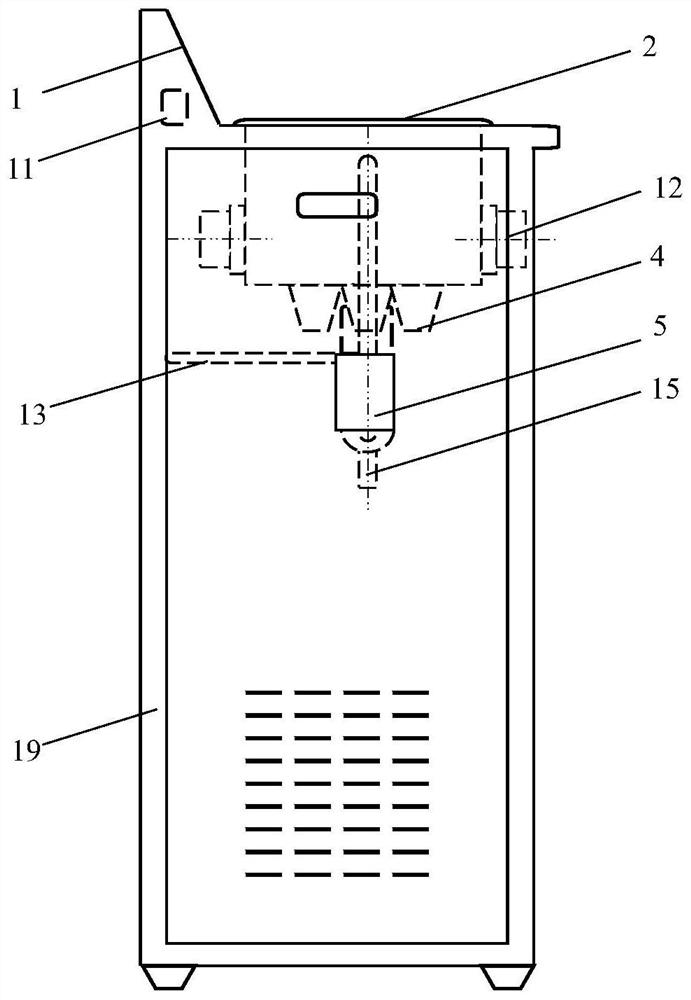

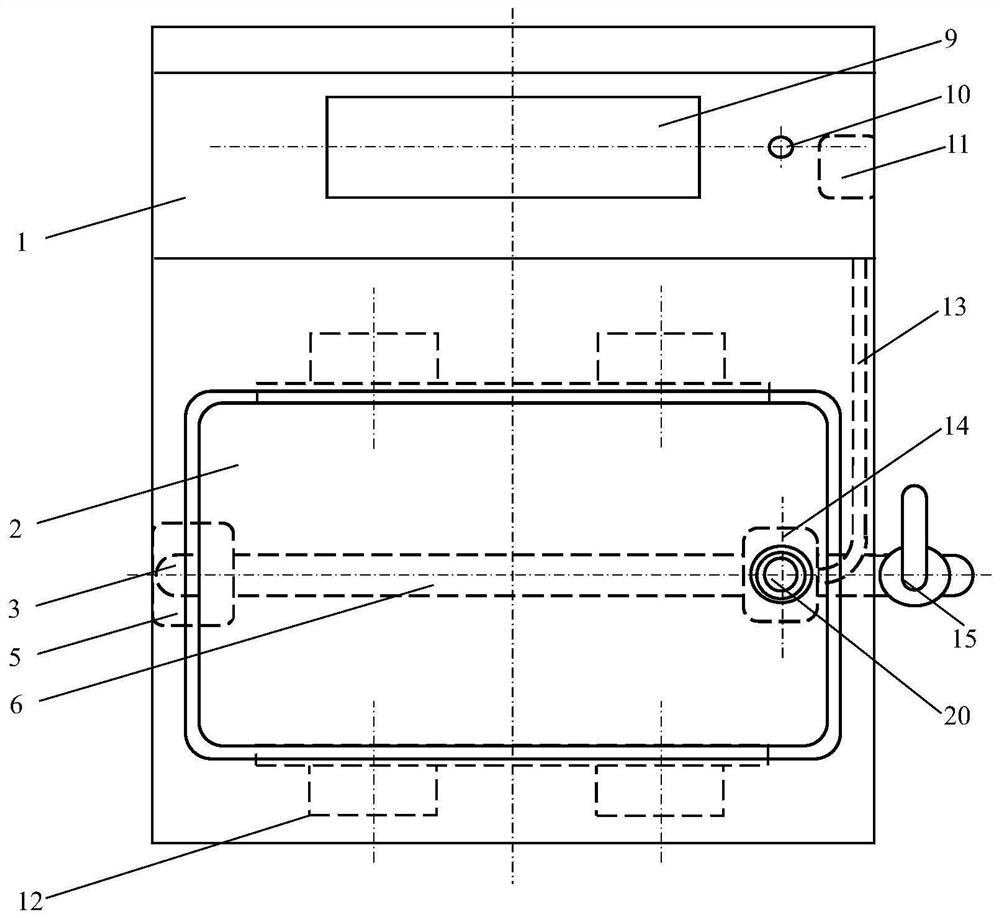

[0035] exist figure 1 In the front view of the device structure shown in the present invention: the operating surface 1 is a mechanism part for man-machine interaction support and operation, which is a rectangular structure of stainless steel sheet material, pasted on the top rear side of the body 7, facing forward. The treatment tank 2 is a body component for containing the treatment liquid of the target object, and is a rectangular parallelepiped tank structure made of 304 stainless steel, and is assembled on the upper end of the body 7 . The return pipe 3, as a processing liquid circulation and homogeneous body running component, is a 304-type stainless steel circular tube structure, and is assembled in the cavity between the left wall of the casing on the left side of the body 7 and the left wall of the treatment tank 2. The transducer 4 is used as an element for converting the electric energy of the ultrasonic frequency into mechanical energy of the same frequency, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com