Monolithic magnetic property measuring device based on spatial orthogonal triaxial stress loading condition

A technology of triaxial stress and measuring device, applied in the direction of magnetic performance measurement, etc., can solve the problem of reducing the excitation effect of the magnetic circuit, and achieve the effect of overcoming measurement limitations, good low temperature resistance, and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

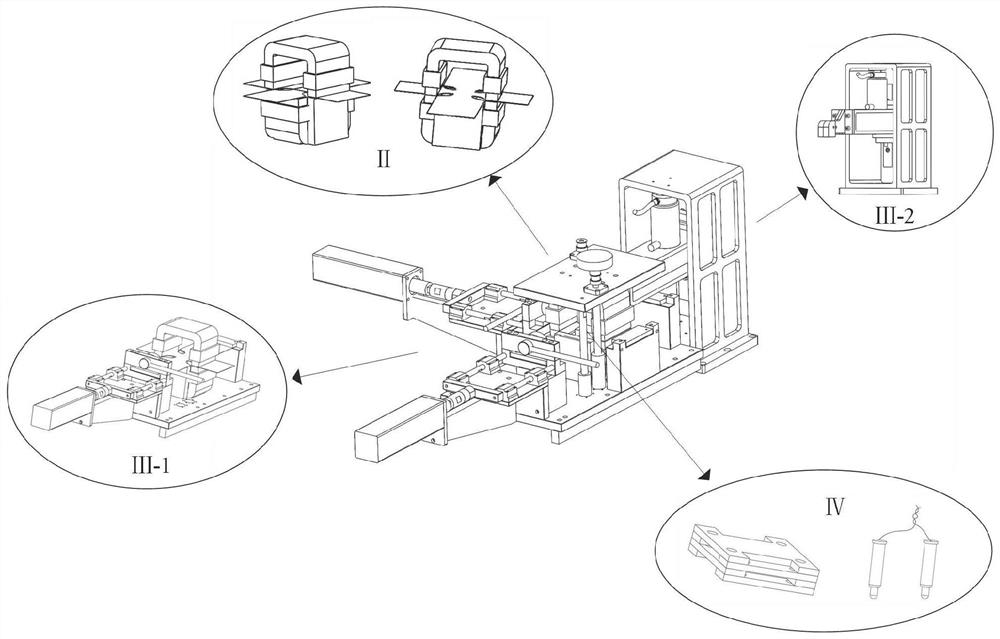

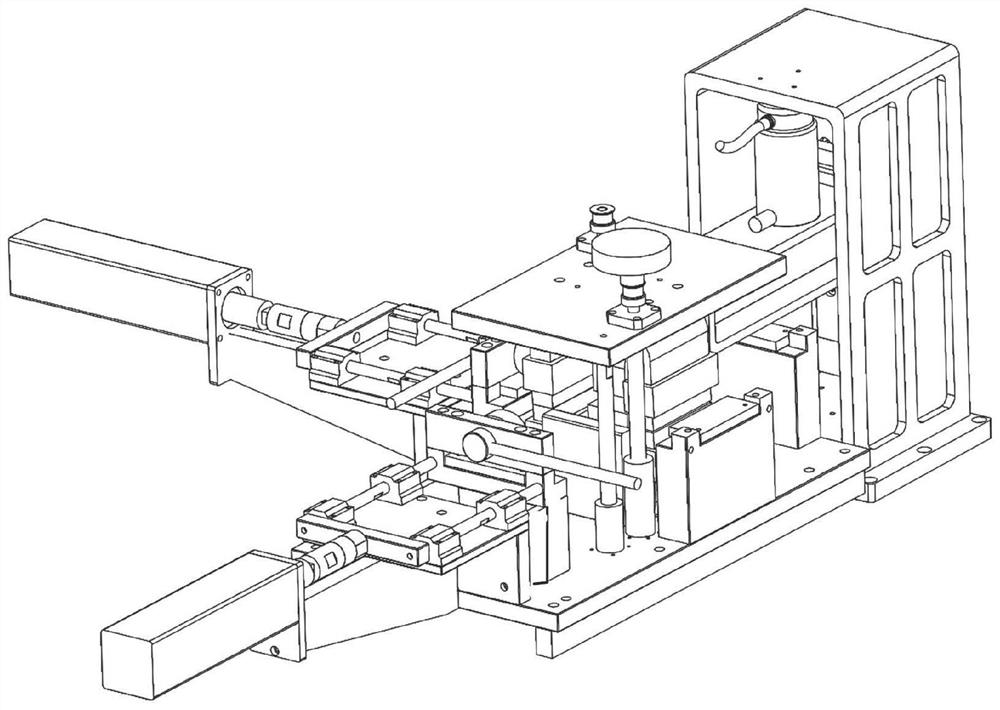

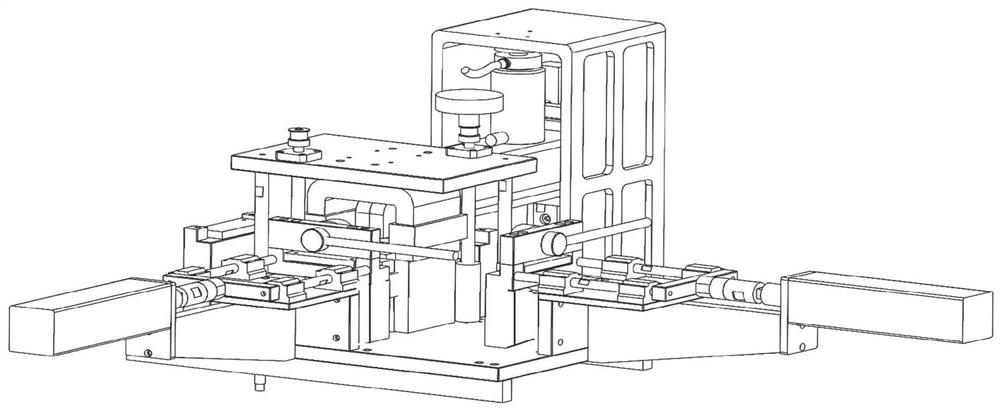

[0063] The present invention provides a monolithic magnetic characteristic measurement device (referred to as the measurement device) under the condition of spatially orthogonal triaxial stress loading, which is characterized in that the measurement device is as figure 1 As shown, it includes control module I, excitation module II, triaxial stress application module III (including X-axis, Y-axis stress application structure III-1 and Z-axis stress application structure III-2) and measurement module IV;

[0064] The control module I includes a PA100-52A power amplifier and an industrial computer (the invention is specifically a Lenovo computer); the industrial computer is used to send an excitation signal to the excitation module II, send a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com