A split stator moving iron core permanent magnet linear oscillating motor

A permanent magnet linear and oscillating motor technology, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of short service life of permanent magnets, large motor noise and vibration, low output thrust density, etc. Improved safety performance and reduced noise and vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

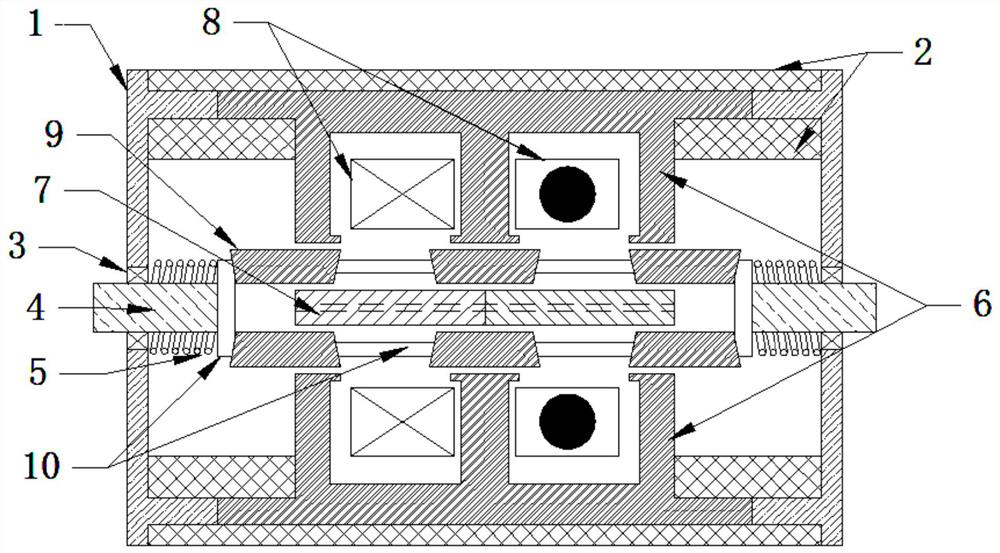

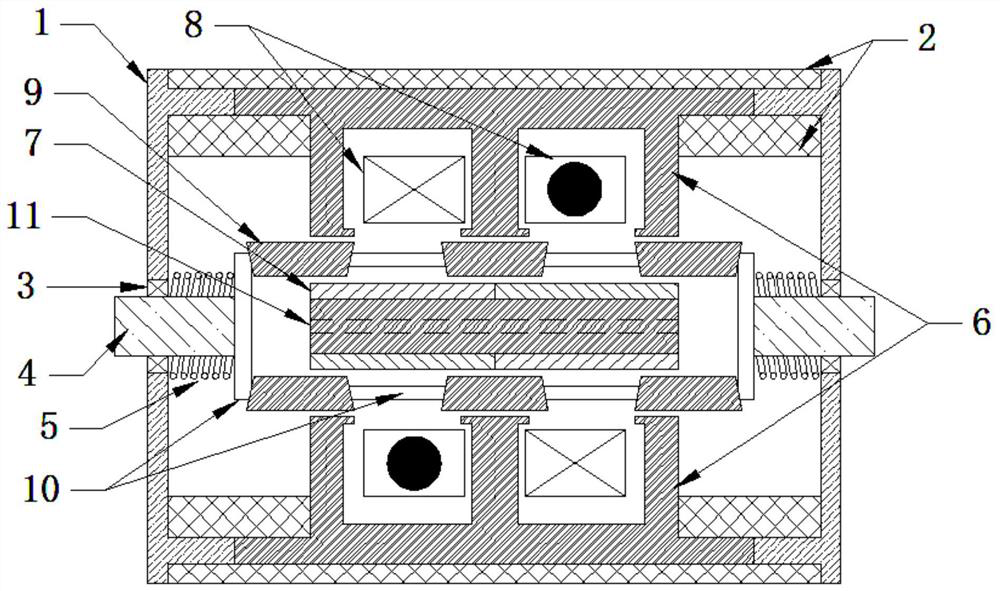

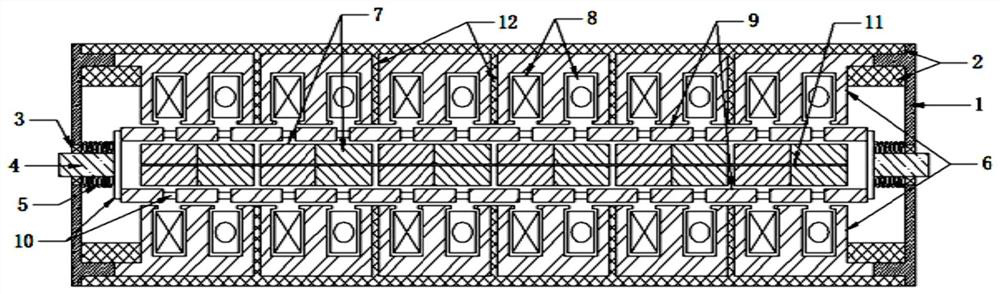

[0066] figure 1 A schematic diagram of the longitudinal cross-sectional structure of the stator split type moving iron core type permanent magnet linear oscillating motor designed according to the present invention when the magnetizing direction is the same as that of the vertical side permanent magnet, figure 2 It is a schematic diagram of the longitudinal cross-sectional structure of the stator split type moving iron core type permanent magnet linear oscillating motor designed according to the present invention when the magnetizing direction of the vertical side permanent magnet is opposite, including a rectangular end cover 1, a casing 2, a linear motion bearing 3, Movement shaft 4, resonance spring 5, outer stator iron core 6, inner stator permanent magnet 7, armature winding 8, mover iron core 9, mover iron core support 10 and inner stator iron core 11; among them, the outer stator iron core 6 is composed of two parts that are symmetrical up and down, and the stator teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com