Electric vehicle controller based on single-tube parallel connection

A technology of electric vehicles and controllers, which is applied in the direction of electric vehicles, motor control, control systems, etc., can solve the problems of unable to meet the cost requirements of motor controllers, high costs, poor vibration resistance, etc., to achieve convenient layout and Assembly, good heat dissipation requirements, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

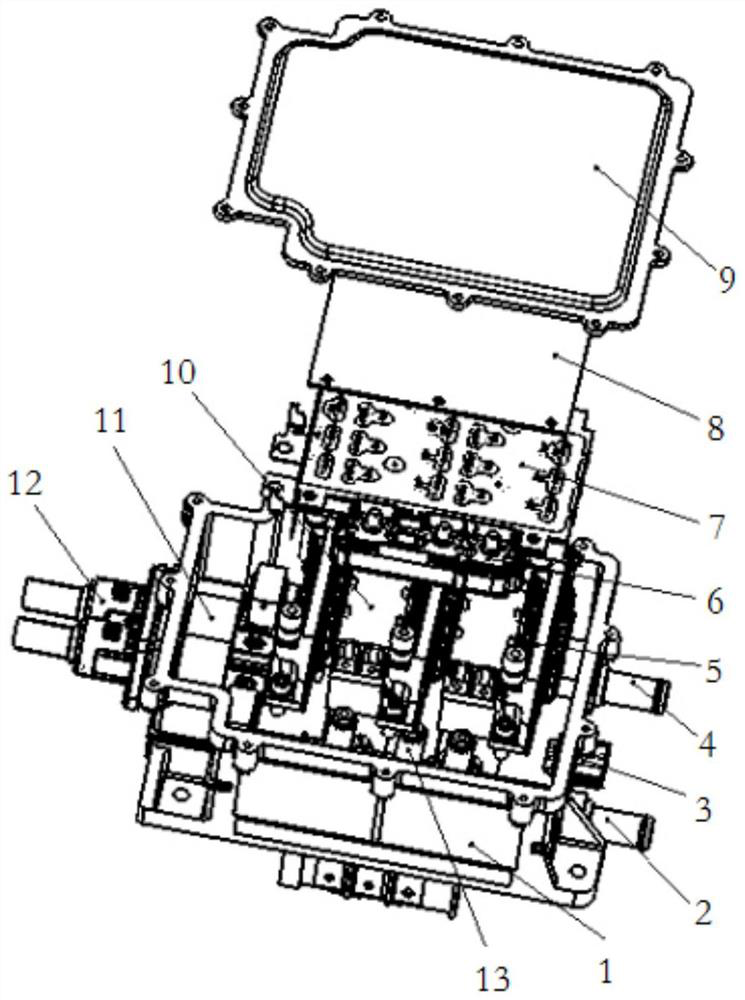

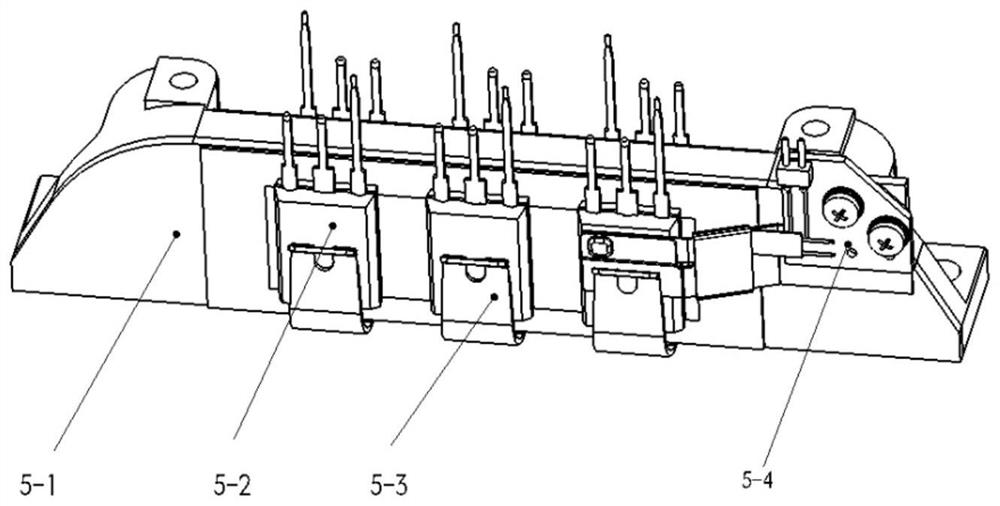

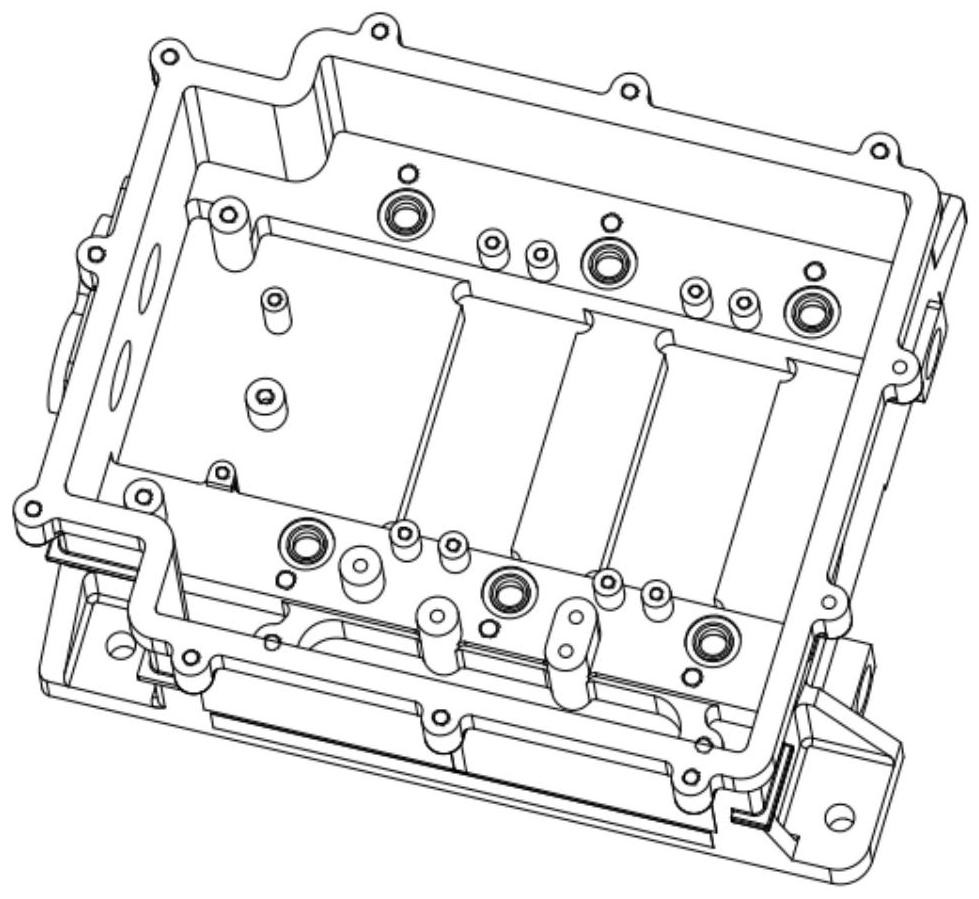

[0032] like figure 1 As shown, the present application proposes an electric vehicle controller based on single-tube parallel connection, including a box body 1 and a box cover 9 covered on the box body 1, and the box body 1 is provided with a film capacitor 10, a magnetic ring assembly 11, a current Sensor assembly 6, composite busbar 7, PCBA control board 8, single-pipe cooling assembly 5 and three-phase plastic-coated pole plate 13. Wherein, the film capacitor 10 is connected to the composite busbar 7 . The input end of the three-phase plastic-coated pole plate 13 is electrically connected to the three-phase output end of the composite busbar 7 , and the output end extends out of the box body 1 and is electrically connected to the three-phase input end inside the motor.

[0033] A signal plug-in 3 , a busbar plug-in 12 , a water inlet pipe 2 and a water outlet pipe 4 are arranged on the side wall of the box body 1 . The signal plug-in 3 is electrically connected with the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com