A kind of fiber acoustic transducer and its preparation method and application

An acoustic transducer and fiber technology, applied in the field of acoustics, can solve problems such as inability to integrate, and achieve the effects of high output power, high sound quality, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

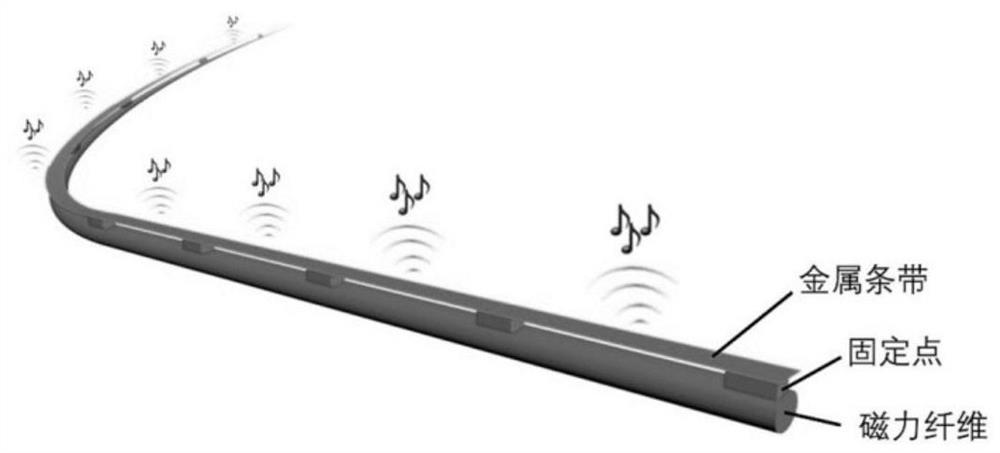

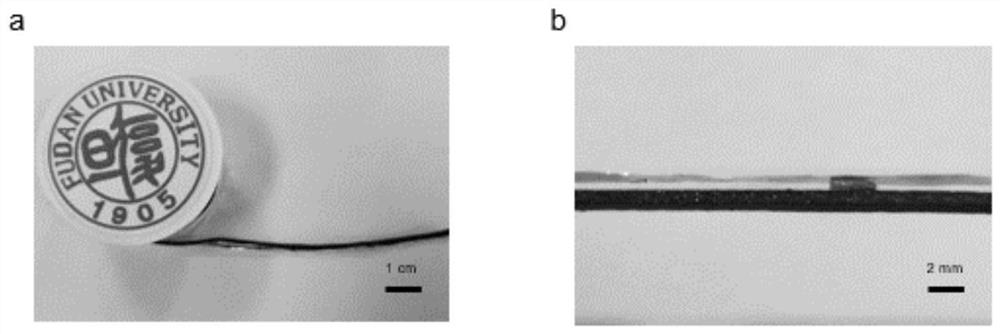

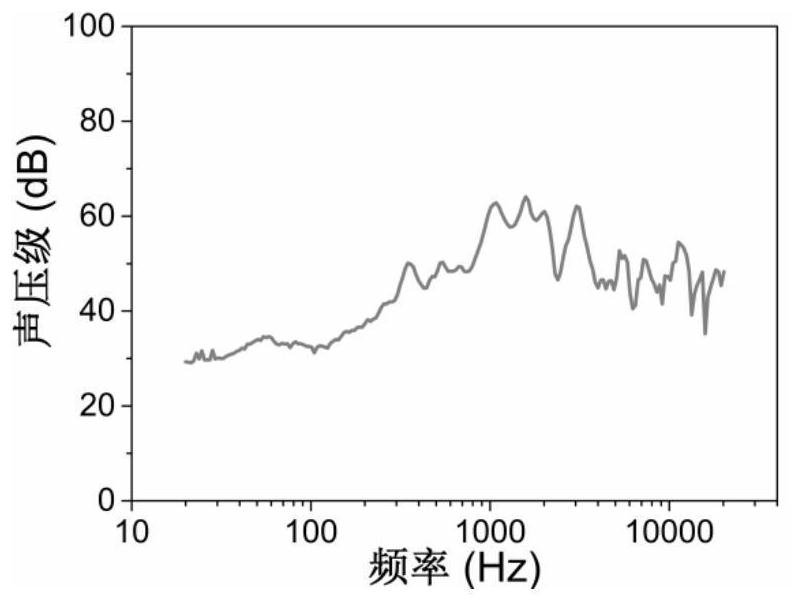

[0027] (1) Preparation of the fiber acoustic transducer: select an aluminum strip with a length of 30 cm, a width of 1 mm, and a thickness of 10 μm. Choose a flexible NdFeB magnetic fiber with a length of 20 cm and a cross section of a square with a side length of 1 mm. Fix the aluminum strip on the flexible NdFeB magnetic fiber by fixing a point every 25 mm. Leave 5cm lead electrodes on each side. The obtained acoustic transducer can emit 40-60 dB of sound in the range of audible sound (20-20,000 Hz) at a distance of 1 cm when used as a loudspeaker. When used as a microphone, it can clearly record the waveform of the sound wave;

[0028] (2) Realize directional sound by fiber speaker: bend the fiber speaker with a length of 140 cm into a circular arc with a radius of 64 cm. A sine wave alternating current with a current of 1A and a frequency of 1000 Hz is applied to both ends. Use Umik-1, miniDSP microphone to measure the sound pressure level at the center of the circle a...

Embodiment 2

[0032] (1) Preparation of the fiber acoustic transducer: select an aluminum strip with a length of 30 cm, a width of 1 mm, and a thickness of 15 μm. Choose a flexible NdFeB magnetic fiber with a length of 20 cm and a cross section of a square with a side length of 1 mm. Fix the aluminum strip on the flexible NdFeB magnetic fiber by fixing a point every 11 mm. Leave 5cm lead electrodes on each side. The resulting acoustic transducer can emit 40-60 dB of sound in the audible sound range (20-20,000 Hz) at a distance of 1 cm when used as a loudspeaker. When used as a microphone, it can clearly record the waveform of the sound wave;

[0033](2) Realize directional sound by fiber speaker: bend the fiber speaker with a length of 140 cm into a circular arc with a radius of 64 cm. A sine wave alternating current with a current of 1A and a frequency of 1000 Hz is applied to both ends. Use Umik-1, miniDSP microphone to measure the sound pressure level at the center of the circle and ...

Embodiment 3

[0037] (1) Preparation of the fiber acoustic transducer: select an aluminum strip with a length of 30 cm, a width of 1 mm, and a thickness of 20 μm. Choose a flexible NdFeB magnetic fiber with a length of 20 cm and a cross section of a square with a side length of 1 mm. Fix the aluminum strip on the flexible NdFeB magnetic fiber by fixing a point every 50mm. Leave 5cm lead electrodes on each side. The obtained acoustic transducer can emit 40-55 dB of sound in the audible sound (20-20,000 Hz) range at a distance of 1 cm when used as a loudspeaker. When used as a microphone, it can clearly record the waveform of the sound wave;

[0038] (2) Realize directional sound by fiber speaker: bend the fiber speaker with a length of 140 cm into a circular arc with a radius of 64 cm. A sine wave alternating current with a current of 1A and a frequency of 1000 Hz is applied to both ends. Use Umik-1, miniDSP microphone to measure the sound pressure level at the center of the circle and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com