Gas sensor

A gas and gas manufacturing technology, which is applied in the fields of instruments, scientific instruments, gaseous chemical plating, etc., can solve the problems of increasing the production cost of the device and increasing the complexity of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

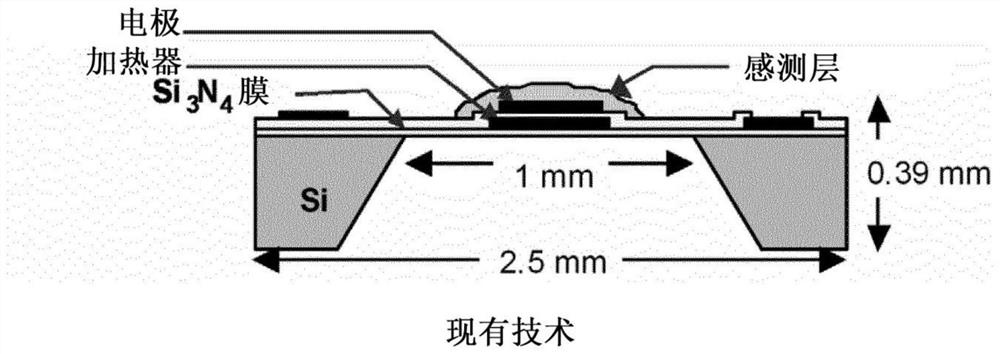

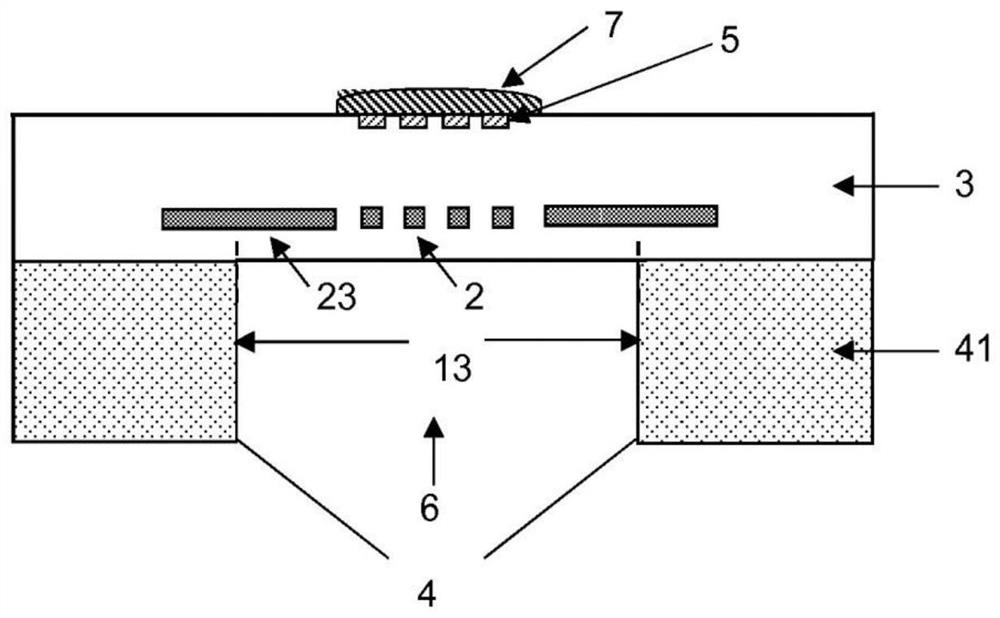

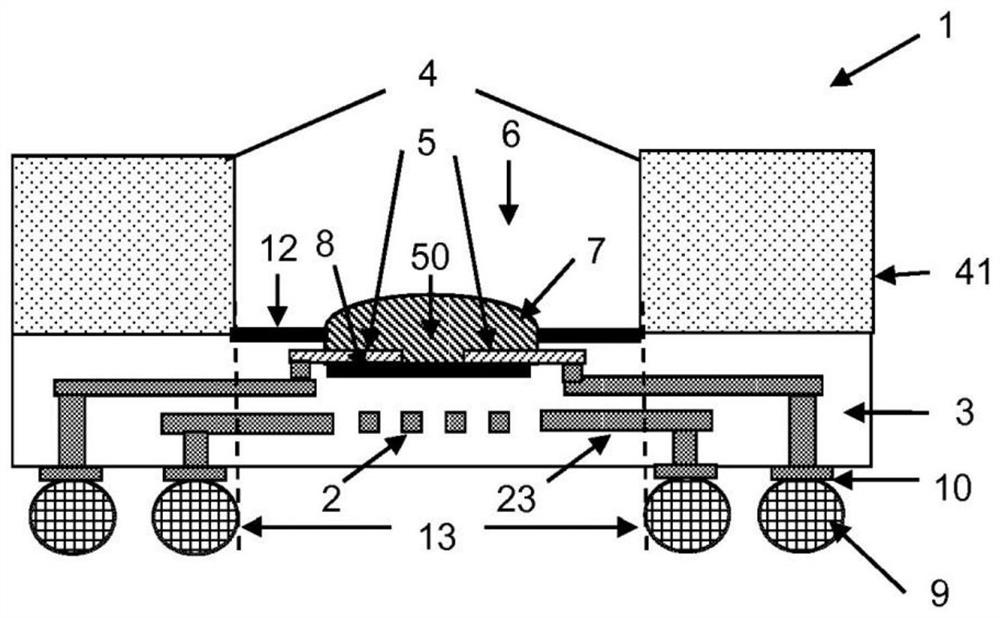

[0135] Some examples of devices are given in the attached drawings.

[0136] figure 2 A cross-section of an exemplary gas sensor 1 is shown. The gas sensor 1 comprises a dielectric layer 3 supported by a semiconductor substrate 41 having an etched portion 6 and a substrate portion 4 . In one example, semiconductor substrate 41 can be made of silicon or silicon carbide. The dielectric layer 3 has a dielectric film region or region 13 positioned immediately or directly adjacent or close to the etched portion or cavity 6 of the substrate 41 . In one example, the dielectric layer 3 can be made of a material such as silicon oxide, silicon nitride or a combination thereof. Dielectric film region 13 corresponds to a region (directly) above or below etched portion 6 of dielectric layer 3 . The substrate 41 is etched by DRIE to form an etched portion or cavity 6 .

[0137] The gas sensing material 7 is deposited or grown on the dielectric film 13 . The gas sensing material 7 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com