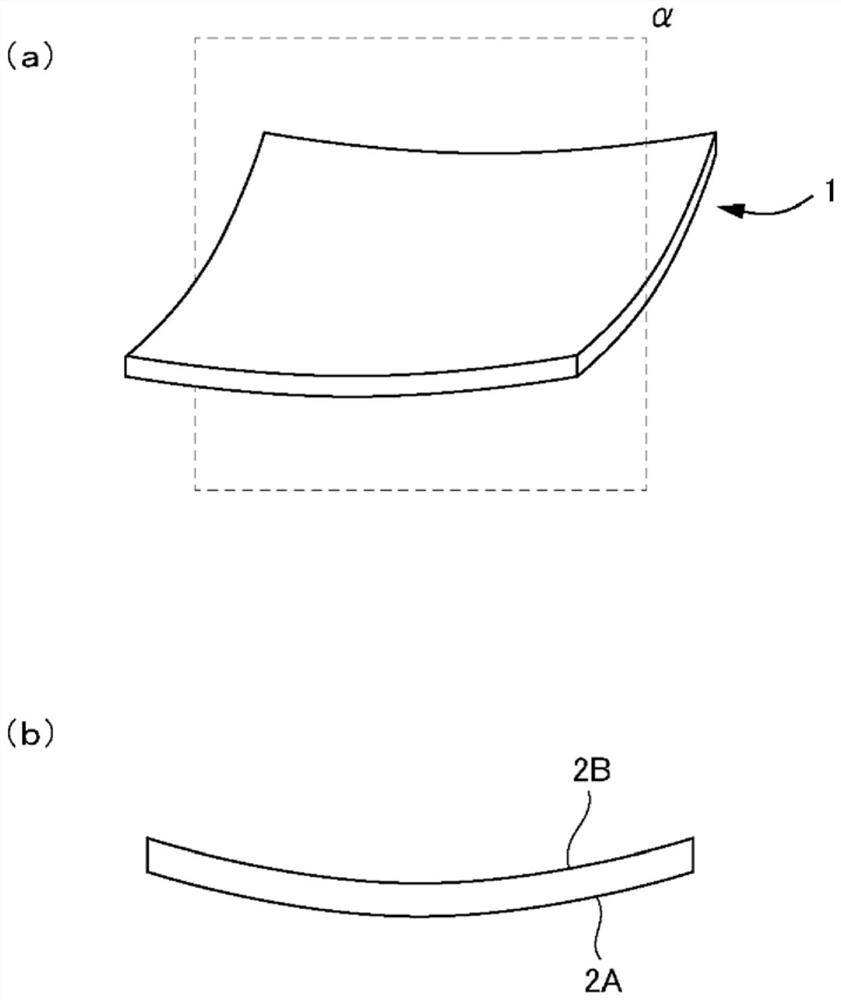

Heat-dissipating member and manufacturing method for same

A manufacturing method and component technology, applied in the field of heat dissipation components and their manufacturing, can solve problems such as reduced thermal conductivity, and achieve the effect of improving manufacturing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

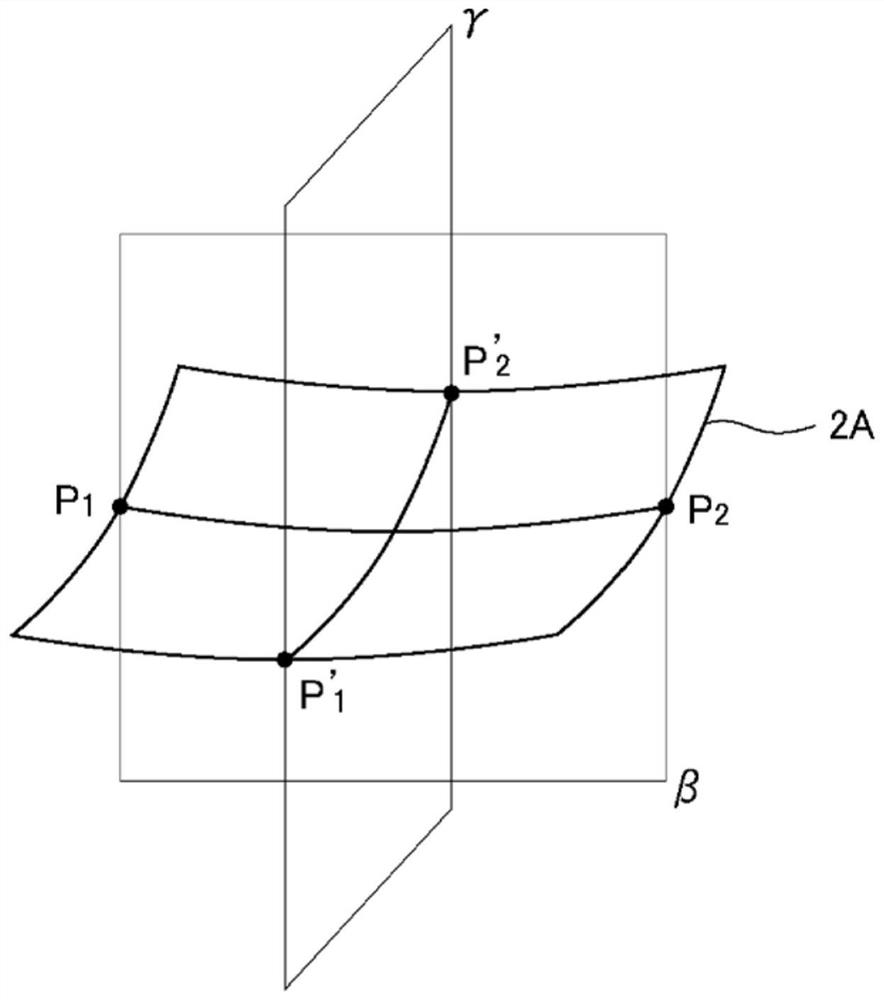

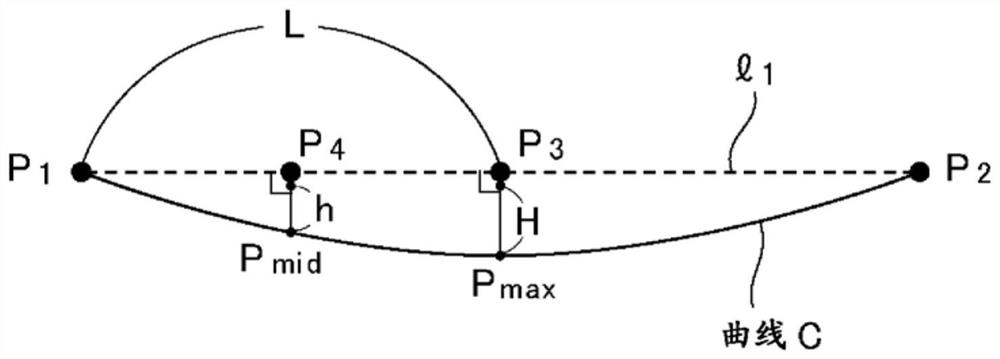

Method used

Image

Examples

Embodiment 1

[0175] (Manufacture of silicon carbide porous body)

[0176] Silicon carbide powder A (manufactured by Pacific Blue Dam Co., Ltd.: NG-150, average particle diameter: 100 μm) 300 g, silicon carbide powder B (manufactured by Yakushima Denko Co., Ltd.: GC-1000F, average particle diameter: 10 μm) 150 g It was mixed with 30 g of silica sol (manufactured by Nissan Chemical Industry Co., Ltd.: Snowtex) with a stirring mixer for 30 minutes. The obtained mixture was put into a mold of 178 mm×128 mm×5.5 mm, and press-molded at a pressure of 10 MPa. This was calcined at a temperature of 900° C. for 2 hours in the air to obtain a silicon carbide porous body.

[0177] For the following process, 30 sheets of the same silicon carbide porous body were fabricated.

[0178] Both sides of the porous silicon carbide body were sandwiched between plates made of stainless steel (SUS304) with a size of 210 mm×160 mm×0.8 mm, and 30 sheets were laminated. Furthermore, after arranging iron plates wit...

Embodiment 2~7

[0199] Except for changing the length of the long side and the short side of the heat dissipation member, and the bending shape of the pressing punch and the pressing die in the above (impartment of bending), the heat dissipation member was produced in the same manner as in Example 1. Then, it carried out similarly to Example 1, and measured various numerical values.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com