Preparation method and preparation device of soft-shelled turtle compound feed

A technology for compound feed and preparation device, which is applied in the molding or processing of animal feed, feed, animal feed, etc., can solve the problems of poor practicability and use effect, uneven feed quality, poor mixing treatment method, etc. Promote and use, improve quality, treat mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

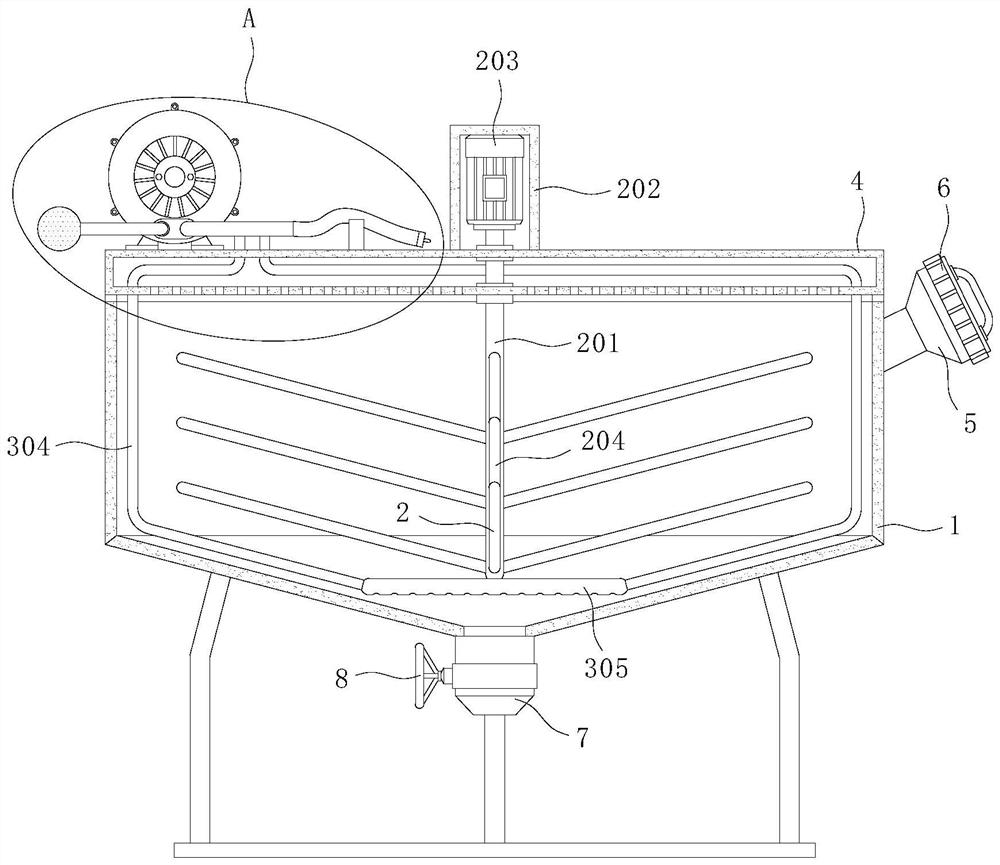

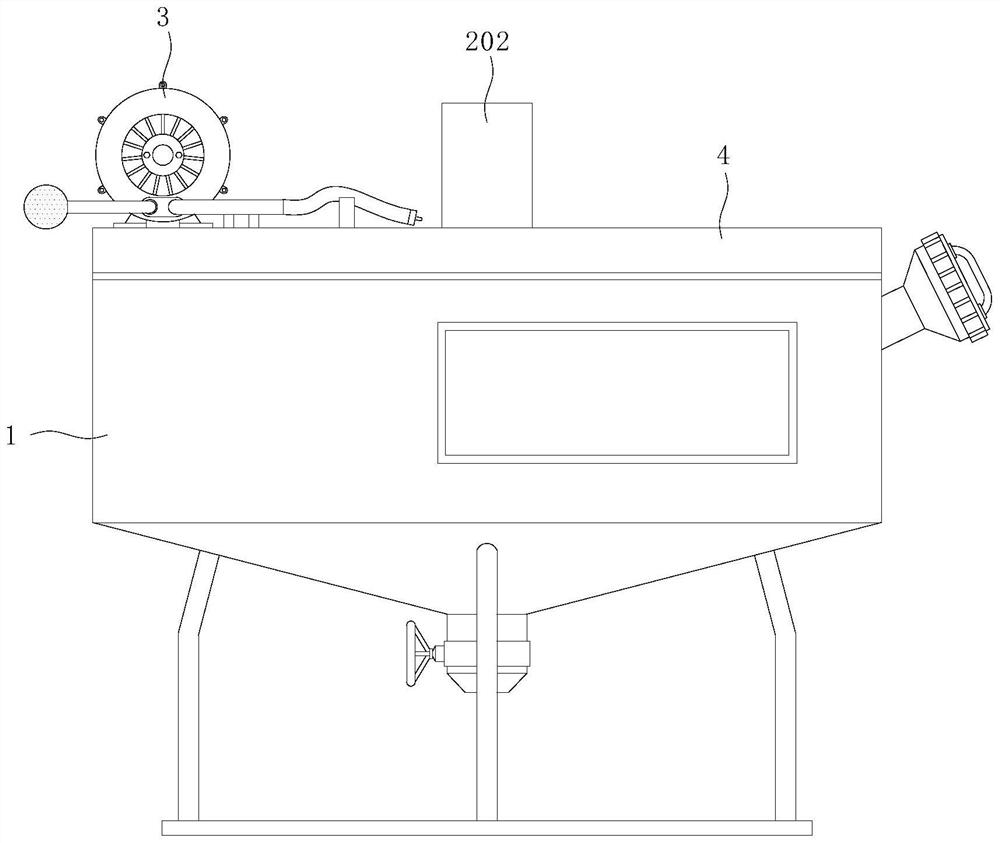

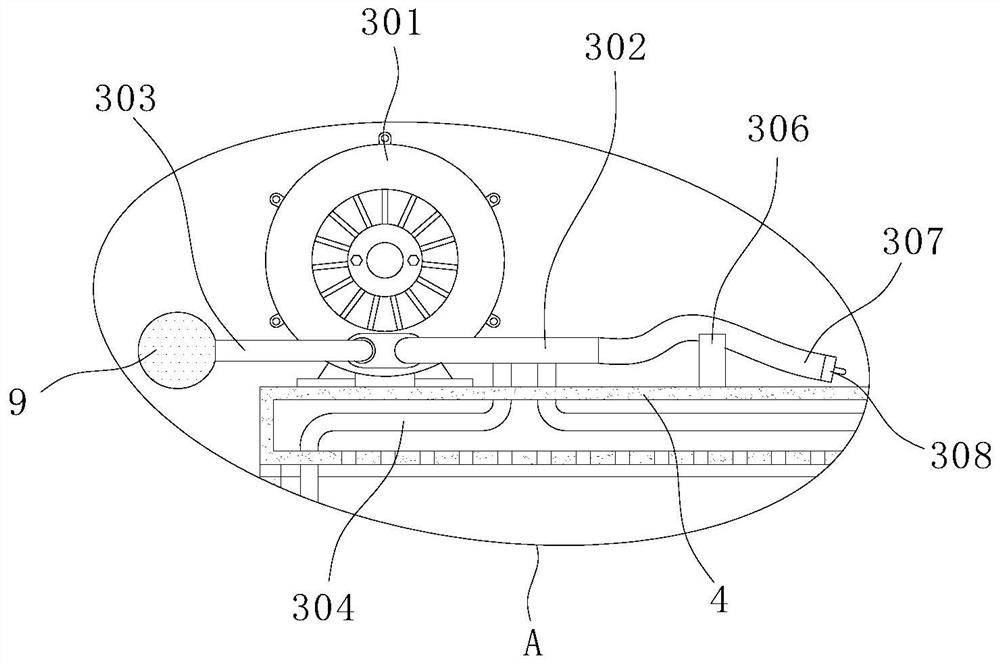

[0026] see Figure 1-5 , the present invention provides a technical solution: a method for preparing soft-shelled turtle compound feed, comprising the following steps:

[0027] Powdering: Wash and drain the feed materials and put them into the dehydrator for dehydration. When the moisture content of the feed materials is lower than 1.6%, stop dehydration, take the dehydrated feed materials out of the dehydrator, and then put them into the grinder Carry out pulverization, obtain feed raw material powder after grinding, and feed raw material powder can pass through 180 mesh sieves;

[0028] Wet mixing: Pour the feed material powder into a machine with heating and stirring functions, and then pour a certain amount of water into the machine. The amount of water is 0.35 times that of the feed material powder. Heating and stirring, the heating temperature is controlled at 44° C., the stirring speed is 120 rpm, and after heating and stirring for 45 minutes, a paste feed is obtained;...

Embodiment 2

[0034] see Figure 1-5 , the present invention provides a technical solution: a method for preparing soft-shelled turtle compound feed, comprising the following steps:

[0035] Powdering: Wash and drain the feed materials and put them into the dehydrator for dehydration. When the moisture content of the feed materials is lower than 1.9%, stop dehydration, take the dehydrated feed materials out of the dehydrator, and then put them into the grinder Carry out pulverization, obtain feed raw material powder after grinding, and feed raw material powder can pass through 180 mesh sieves;

[0036] Wet mixing: Pour the feed material powder into a machine with heating and stirring functions, and then pour a certain amount of water into the machine. The amount of water is 0.4 times that of the feed material powder. Heating and stirring, the heating temperature is controlled at 48° C., the stirring speed is 140 rpm, and after heating and stirring for 45 minutes, a paste feed is obtained; ...

Embodiment 3

[0042] see Figure 1-5 , the present invention provides a technical solution: a method for preparing soft-shelled turtle compound feed, comprising the following steps:

[0043] Powdering: Wash and drain the feed materials and put them into a dehydrator for dehydration. When the moisture content of the feed materials is lower than 2.2%, stop dehydration, take the dehydrated feed materials out of the dehydrator, and then put them into the grinder Carry out pulverization, obtain feed raw material powder after grinding, and feed raw material powder can pass through 180 mesh sieves;

[0044] Wet mixing: Pour the feed material powder into a machine with heating and stirring functions, and then pour a certain amount of water into the machine. The amount of water is 0.45 times that of the feed material powder. Heating and stirring, the heating temperature is controlled at 52° C., the stirring speed is 160 rpm, and after heating and stirring for 45 minutes, a paste feed is obtained; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com