Flour impurity and stone removing device and use method thereof

A flour and miscellaneous box technology, applied in the field of flour processing, can solve the problems of reducing the speed of screening, poor sorting effect, single function of the impurity removal device, etc., and achieves the effect of improving purification efficiency and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

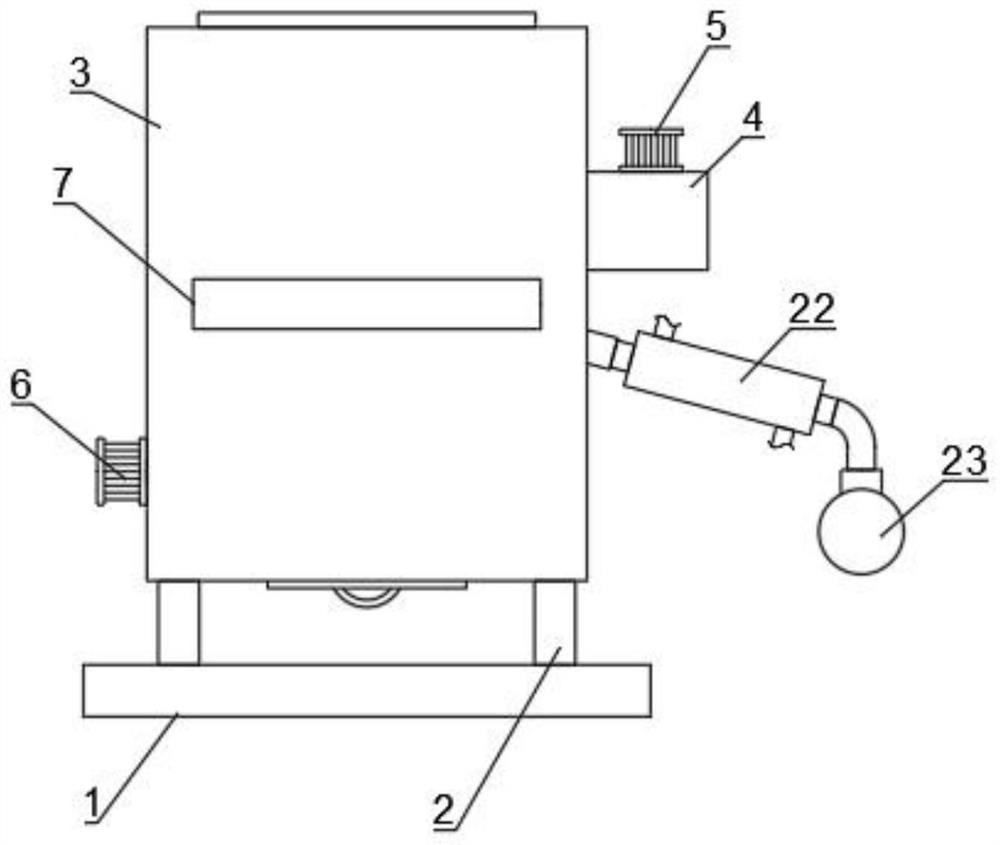

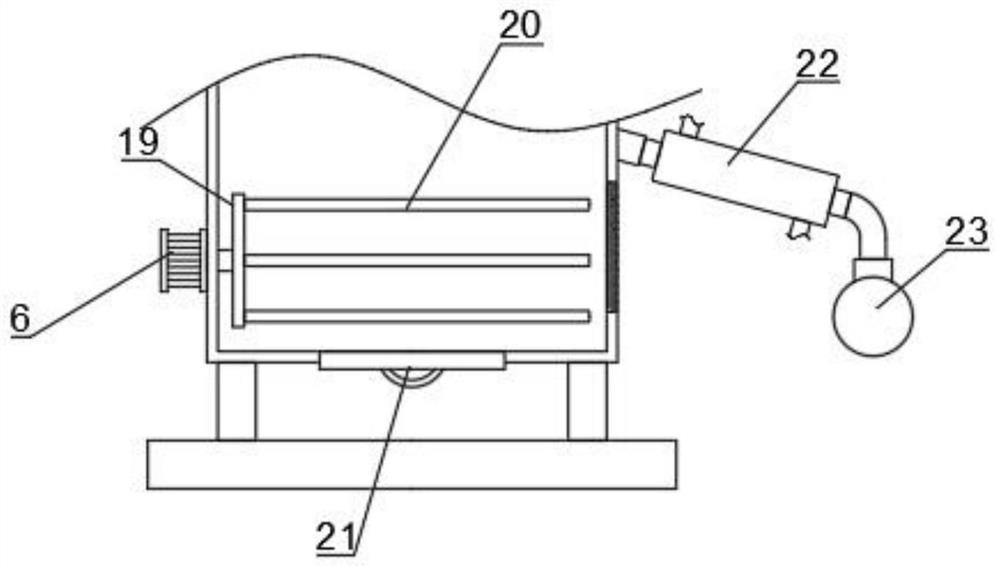

[0028] see Figure 1-4 As shown, a device for removing impurities and stones from flour: comprising an impurity removing box 3, a side box 4, an impurity removing chamber 8, a water removal chamber 24, an impurity removing mechanism and a stirring mechanism;

[0029] The miscellaneous removal box 3 is installed on the base plate 1 through the support column 2. The inner cavity of the miscellaneous removal box 3 is divided into a miscellaneous removal chamber 8 and a water removal chamber 24. Below the trash removal box 3, a filter plate 15 is arranged between the trash removal chamber 8 and the dewatering chamber 24, and the both sides of the filter plate 15 are provided with mounting blocks 14, the mounting blocks 14 are U-shaped structures, and the mounting blocks 14 are fixed by Plate 13 is installed on the inner wall of miscellaneous box 3;

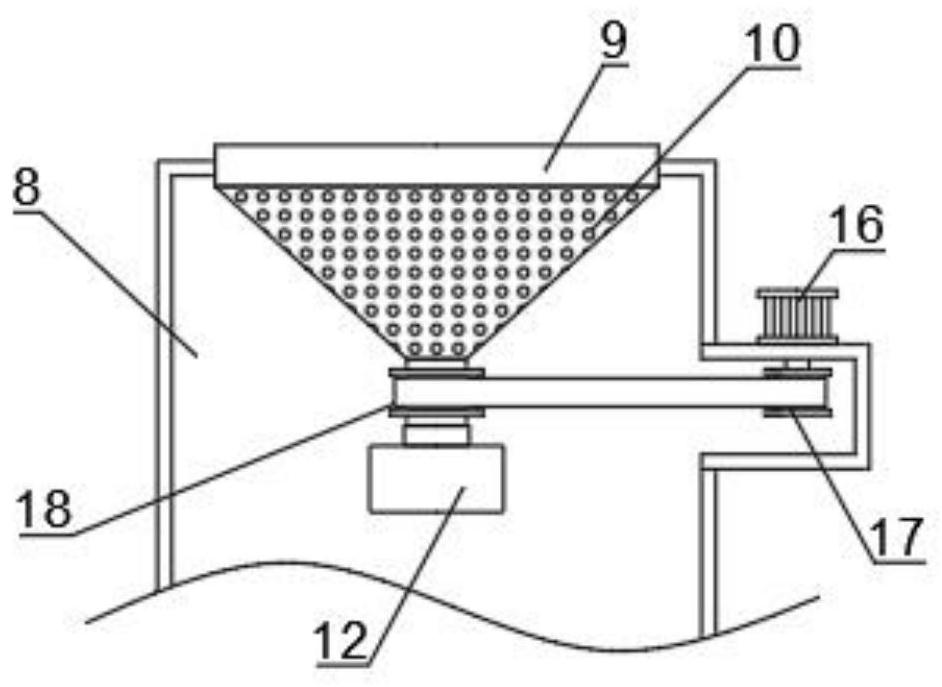

[0030] The impurity removal chamber 8 is provided with an impurity removal mechanism, which includes a filter cartridge 9, a filter...

Embodiment 2

[0041] Compared with Example 1, the difference is:

[0042] A method for using a device for removing impurities and stones from flour, comprising the following steps:

[0043] The first step: mix flour and water, and control the mass ratio of flour and water to 20:300;

[0044] Then, add it in the filter cartridge 9, start the first motor 5 to work, drive the driving pulley 17 to rotate, the driving pulley 17 drives the driven pulley 18 to rotate through the belt 16, and the driven pulley 18 drives the connecting pipe 11 to rotate, so that the filter cartridge 9 is rotated, thereby the flour aqueous solution is filtered, and removes the large-grained stone in the flour; The flour aqueous solution enters in the impurity removal chamber 8 from the filter hole 10; The flour aqueous solution through the preliminary filtration is filtered again through the filter plate 15 to remove Small particle stones; the filtered large particle stones fall into the impurity box 12, and the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com