Mechanical steel plate drilling device with functions of achieving chipping clearing and temperature reducing conveniently

A drilling device and functional technology, applied in the field of mechanical steel plate drilling devices, can solve the problems of easily scalded workers, inconvenient cleaning of debris, inconvenient steel plate horizontal drilling, etc., to facilitate cleaning, collection and recycling, avoid burns, Avoid the splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

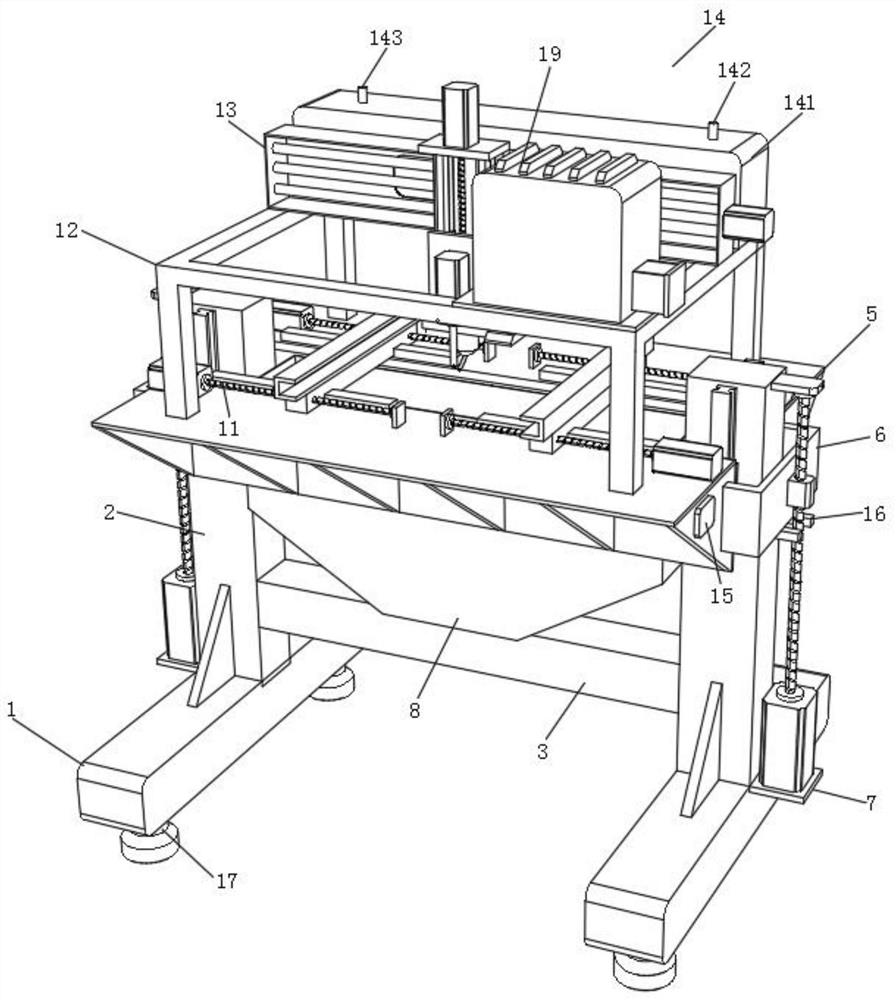

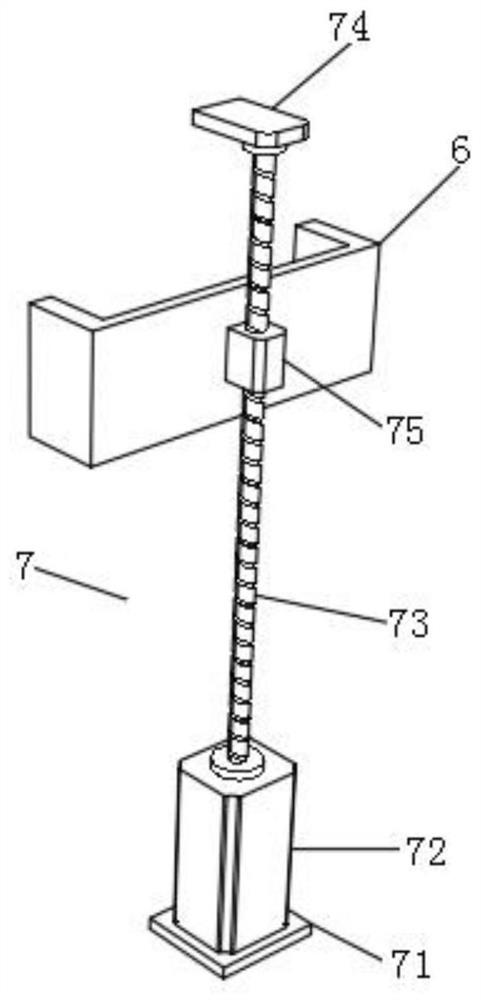

[0028] see Figure 1-7, the present invention provides the following technical solutions: a mechanical steel plate drilling device that is convenient for debris cleaning and temperature cooling, including two support bases 1, the top and middle parts of the two support bases 1 are fixedly connected with support columns 2, and the two support bases A support rod 3 is fixedly connected between the columns 2, and guide rails 4 are fixedly connected to the front and back tops of the two support columns 2, and the guide rail 4 is slidingly connected to the first guide block, and the two first guide blocks on the same surface are connected Table 5 is fixedly connected, the side walls of the same side of the two fixed tables 5 are all fixedly connected with the connecting block 6, the two connecting blocks 6 are fixedly connected with the lifting mechanism 7, and a waste box 8 is fixedly connected between the two fixed tables 5, and the waste material The bottom of the back of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com