Single-welding-point laser welding device and using method

A kind of welding equipment and spot laser technology, applied in the field of single spot laser welding equipment, can solve the problems of deformation, poor welding effect, uneven heating of welded parts, etc., achieve good clamping stability, improve welding quality, and improve welding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

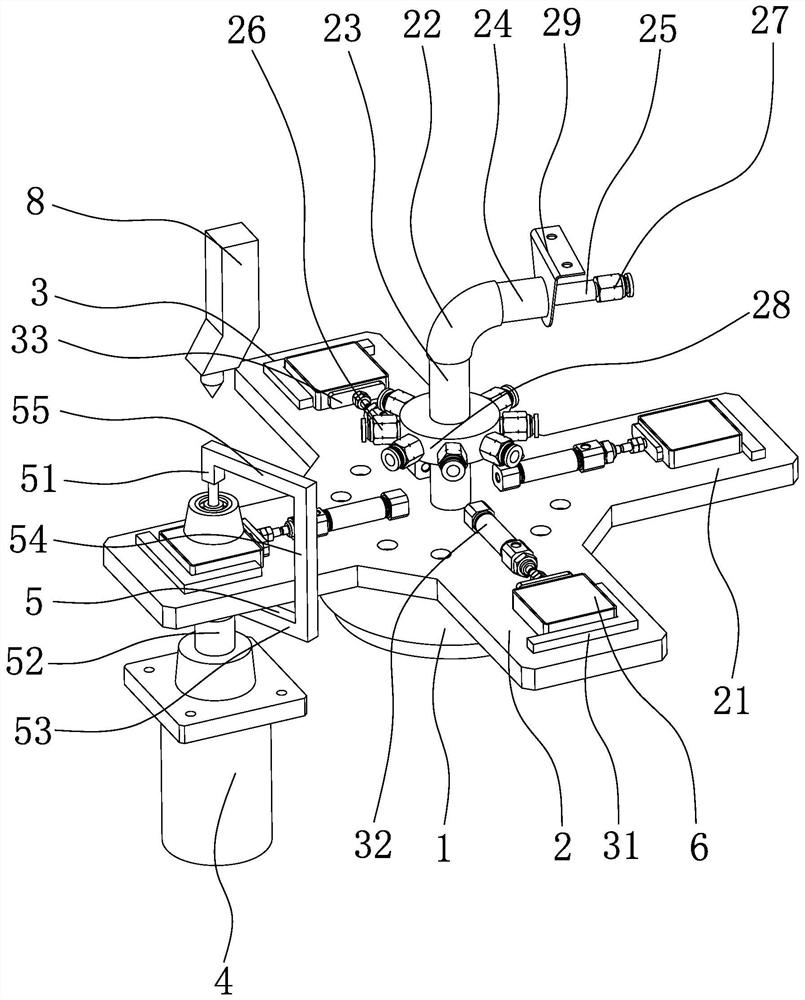

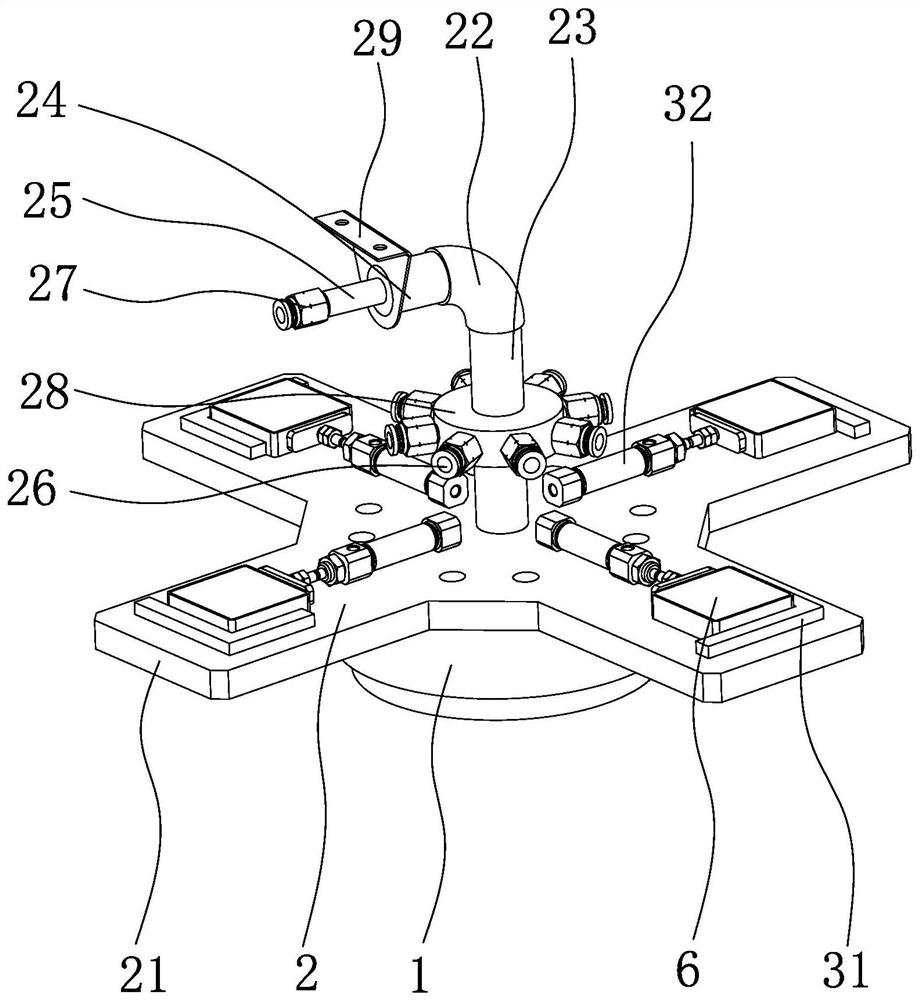

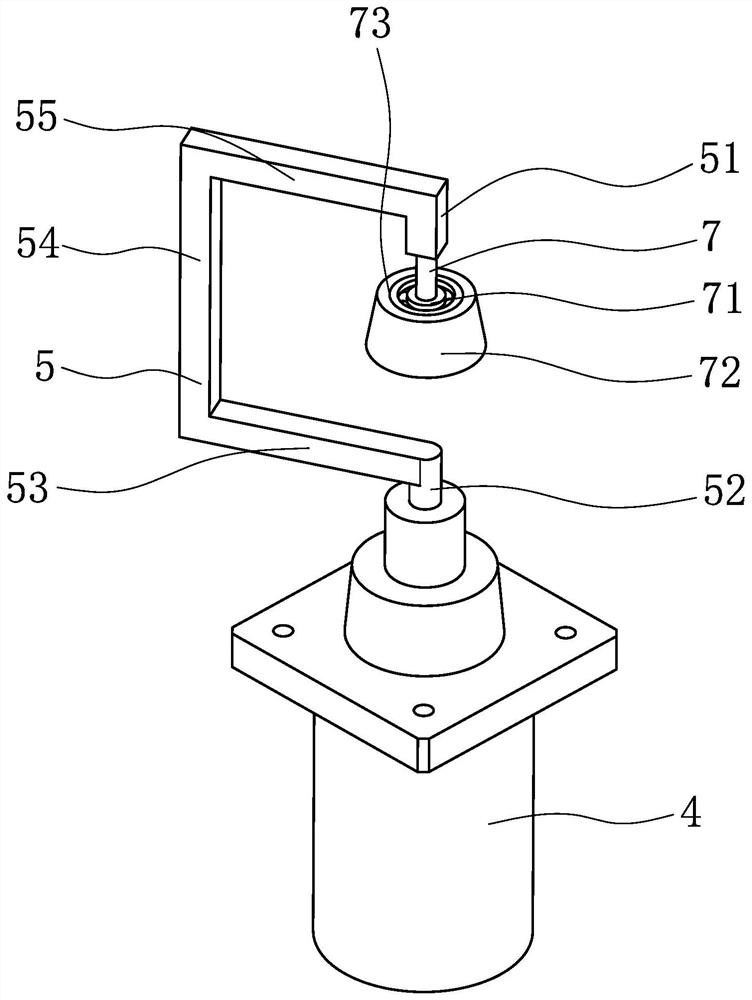

[0027] like Figure 1-4 As shown, the single spot laser welding equipment includes a rotary table 1, on which a work panel 2 is fixed, and the work panel 2 has a number of welding stations 21 that are symmetrical to its center and extend outward. Fixture positioning components 3 are respectively installed on 21, and the rotary table 1 is equipped with a lifting rotary cylinder 4 located below the welding station 21, and the output end above the lifting rotary cylinder 4 is connected with a C-shaped installation that can rotate and lift relative to the welding station 21. Frame 5, the upper end of the C-shaped mounting frame 5 is provided with a downwardly extending compression strip 51, the compression strip 51 is opposite to the welding piece 6 fixed on the welding station 21 and the end is fixed with a rotary pressing head 7, A las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com