Device for recovering and treating hot galvanizing waste acid

A recovery treatment and hot-dip galvanizing technology, which is applied in water/sewage treatment, metallurgical wastewater treatment, neutralized water/sewage treatment, etc., can solve the problems of poor waste acid treatment capacity, achieve high utilization rate, improve safety, bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

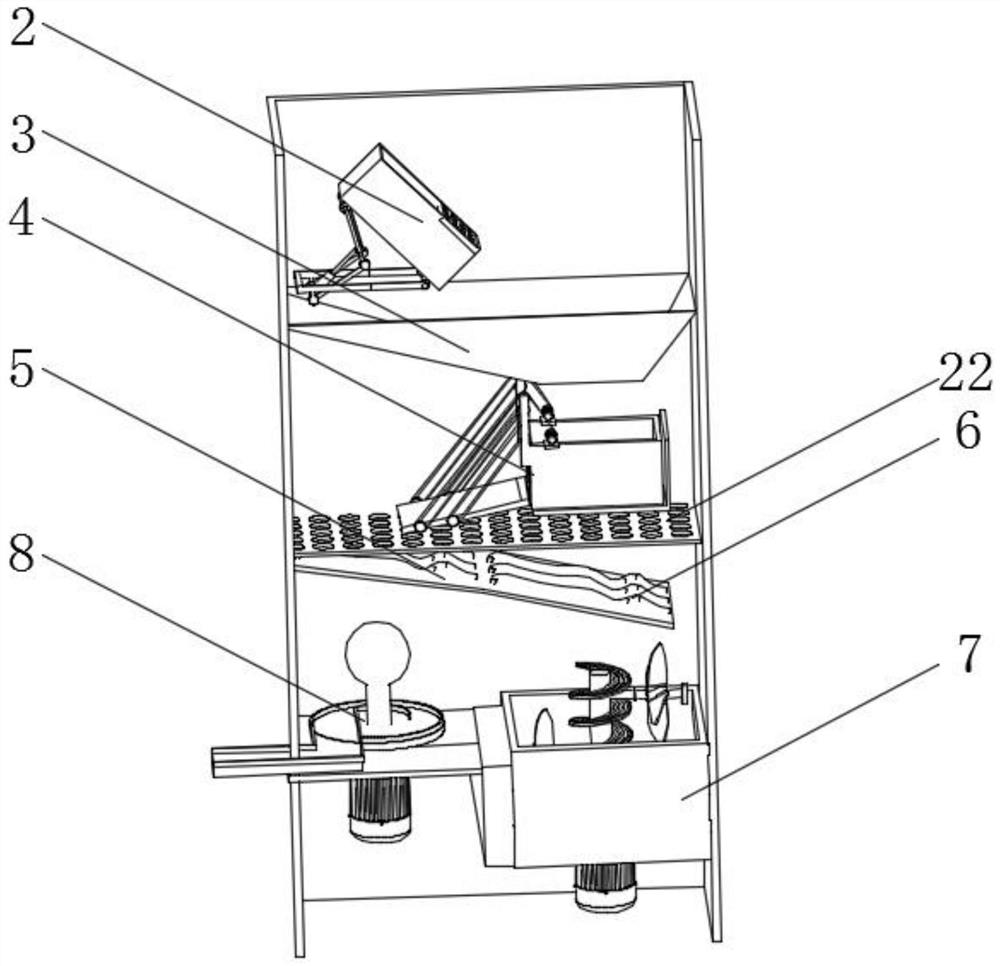

[0024] see Figure 1-4 , in an embodiment of the present invention, a device for recovering and treating waste acid of hot-dip galvanizing includes a box body 1, an oxidation assembly 2 is fixedly connected to the inside of the box body 1, and the bottom of the oxidation assembly 2 is located in the box The inside of the body 1 is fixedly connected with a collection tank 3, the collection tank 3 is in the shape of a groove, and a precipitation component 4 is provided below the collection tank 3, and a drainage plate 5 is provided under the precipitation component 4, Heating wires 6 are fixedly connected to the drain plate 5, and the number of the heating wires 6 is three, and three identical heating wires 6 are fixedly connected above the drain plate 5, and one below the drain plate 5 An evaporating assembly 7 is provided on one side, and a condensed water recovery assembly 8 is provided on the other side of the evaporating assembly 7 inside the box body 1 .

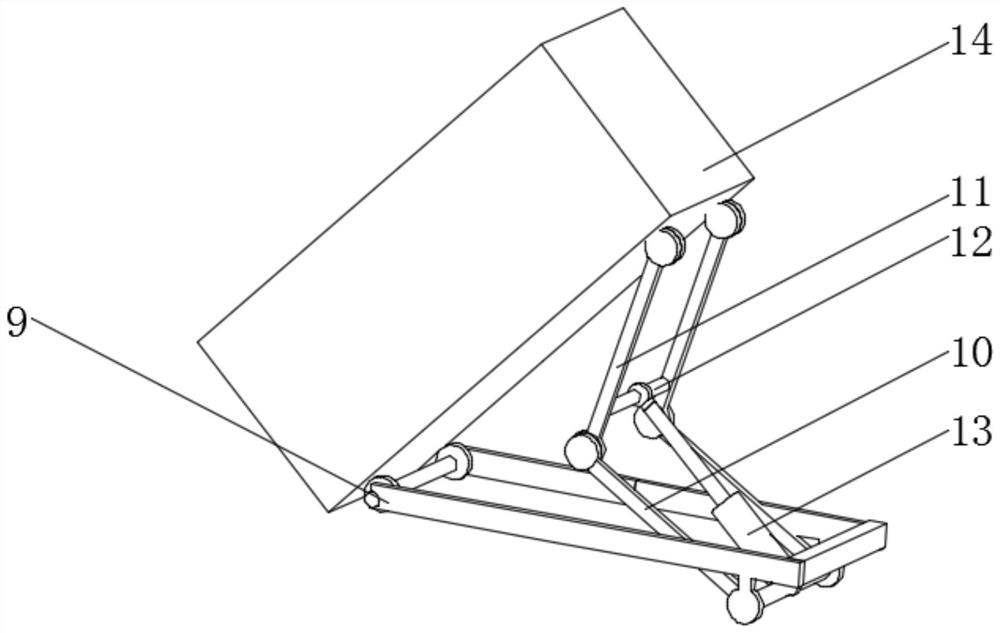

[0025] The oxid...

Embodiment 2

[0027] like figure 1 and Figure 5 As shown, different from Example 1, in another preferred mode provided by the present invention, the separation assembly 4 includes a separation box 16, and one side of the separation box 16 is fixedly connected to a filter piece B17, and the separation The bottom of the box 16 is fixedly connected with the box body 1, the top of the separation box 16 is fixedly connected with a servo motor A18, the output end of the servo motor A18 is fixedly connected with a rotating wheel 19, and the rotating wheel 19 is fixedly connected with a Cable 20, the outer side of the cable 20 is also rotatably connected with the same turning wheel 19, the turning wheel 19 is rotatably connected with the separation box 16, and the separation box 16 is connected with three same turning wheels 19, so The outside of the cable 20 is also connected with the same turning wheel 19, the same turning wheel 19 is rotatably connected with a movable plate 21, and the movable...

Embodiment 3

[0029] like Image 6As shown, different from Embodiment 2, in another preferred mode provided by the present invention, the evaporation assembly 7 includes a servo motor B23, and a heating tank 24 is fixedly connected to the output end of the servo motor B23. The inside of the heating tank 24 is fixedly connected with heating tubes, the number of the heating tubes is four, and four identical heating tubes are fixedly connected inside the heating tank 24, and the heating tank 24 is also fixedly connected with a stirring blade 25, the outer side of the stirring blade 25 is fixedly connected with a magnetic block, and the magnetic block is also installed on the stirring blade 25, and the other side of the heating tank 24 is fixedly connected with the same stirring blade 25, and the servo motor B23 is started to make The heating tank 24 rotates, the heating pipe in the heating tank 24 makes the solution evenly heated, the stirring blade 25 on the heating tank 24 rotates, and under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com