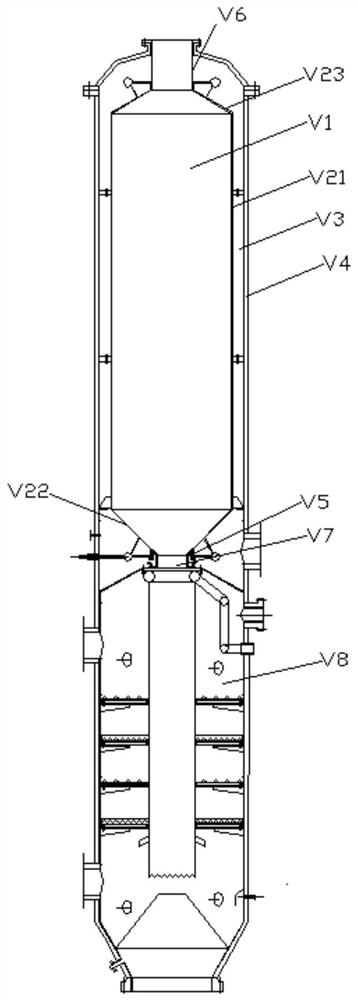

Water-cooled wall lining and gasification furnace comprising same

A water-cooled wall and gasifier technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of large heat loss, low effective utilization of gasifier space, low thermal efficiency, etc., to reduce maintenance costs and improve utilization. Efficiency, the effect of reducing wall heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

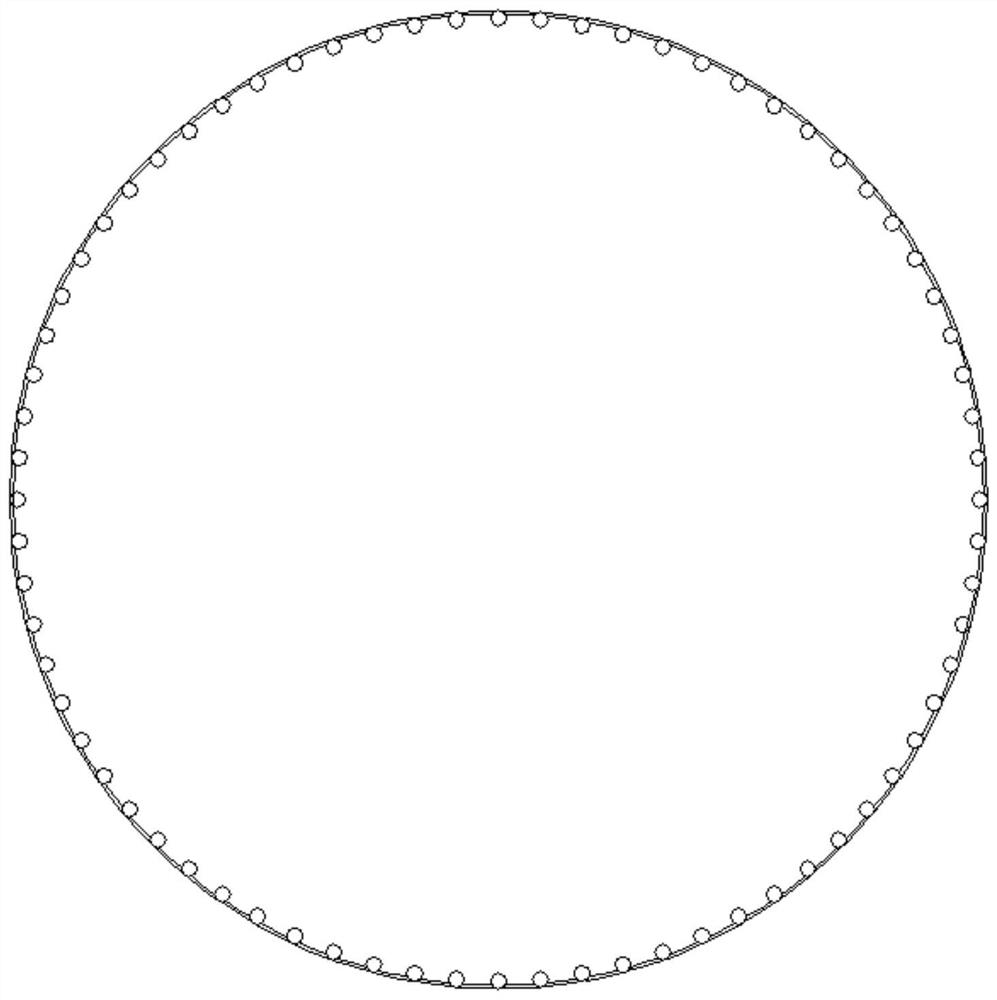

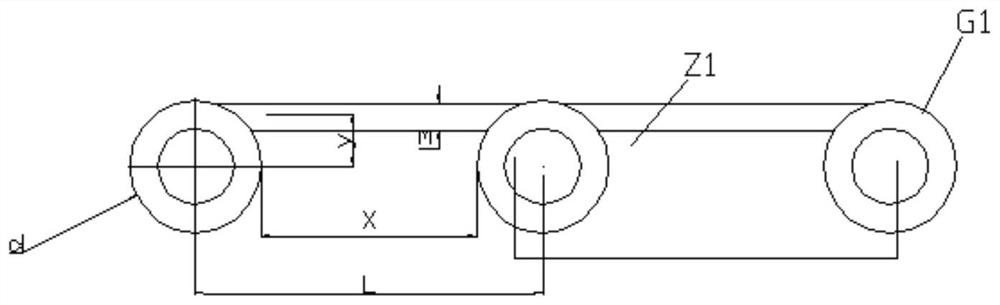

[0053] A water-cooled wall gasifier with a daily coal processing capacity of 1,500 tons uses pulverized coal as raw material for gasification; the gasification pressure is 4.0MPa, and the refractory lining is a tubular water-cooled wall. The coal consumption of the gasifier is 1500 tons / day, the inner diameter D of the water cooling wall of the gasification chamber is 2400 mm, the height H of the gasification chamber is 8000 mm, and the gasification temperature is 1500 °C. The outer diameter of the water-cooling tube is 38mm, the gap between the tubes is 150mm, the thickness of the connecting rib plate is 8mm, and the offset distance of the center line of the connecting rib plate is 15mm. It is covered with 16mm SiC refractory coating, and the surface of the connecting rib is filled with 50mm thick SiC refractory material. Other structural parameters are shown in Table 1.

Embodiment 2

[0055] The processing capacity of the gasifier is 2,000 tons / day of coal, and the coal-water slurry is used as the raw material for gasification. The gasification pressure is 6.5Mpa, the gasification temperature is 1,300°C, and the outer diameter of the metal shell of the gasifier is 3,000mm. Other conditions are all identical with embodiment 1.

Embodiment 3

[0057] The gasification furnace has a processing capacity of 2,000 tons / day of coal, and uses coal-water slurry as raw material for gasification. The gasification pressure is 6.5Mpa and the gasification temperature is 1300°C. The tube spacing is 68mm, the tube gap is 30mm, the surface of the connecting rib is filled with 20mm thick SiC refractory material, the outer diameter of the metal shell of the gasifier is 3600mm, and other conditions are the same as in 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap