Coal water slurry and preparation method thereof

A technology of coal-water slurry and coal powder, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of water-coke slurry stability deviation, high petroleum coke content, and less research, and achieve good stability , the effect of high coal slurry concentration and low water separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

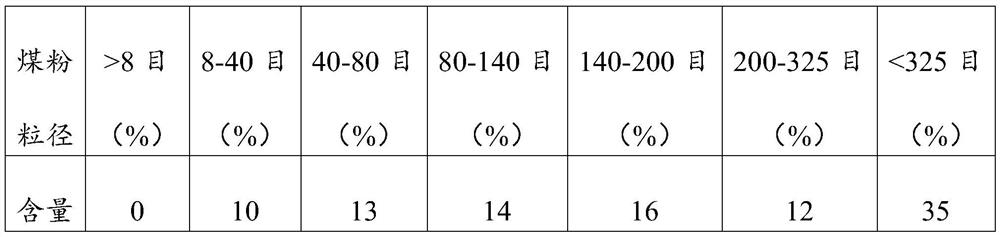

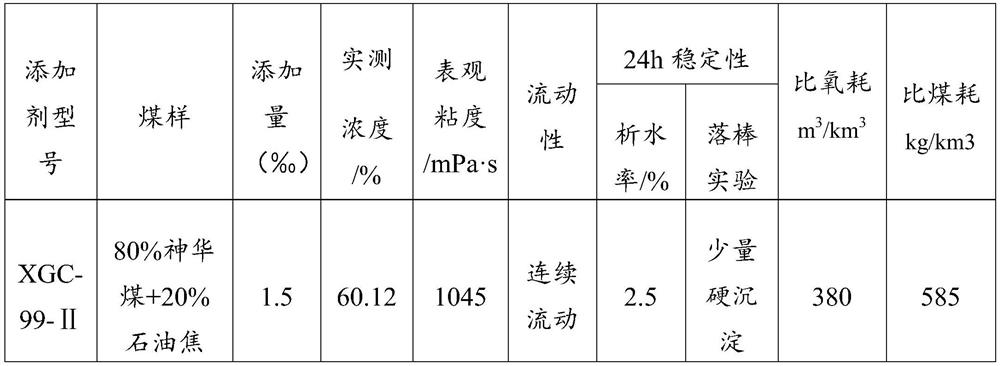

[0036] The present embodiment provides a kind of coal-water slurry, based on the total mass of the coal-water slurry, comprising the following components by weight: 80 parts of coal powder, 20 parts of petroleum coke, 20 parts of water, and the described coal-water slurry also contains additives, The content of the additive is 0.15% of the total mass of coal powder and petroleum coke.

[0037] Present embodiment also provides a kind of preparation method of coal-water slurry, comprises the following steps:

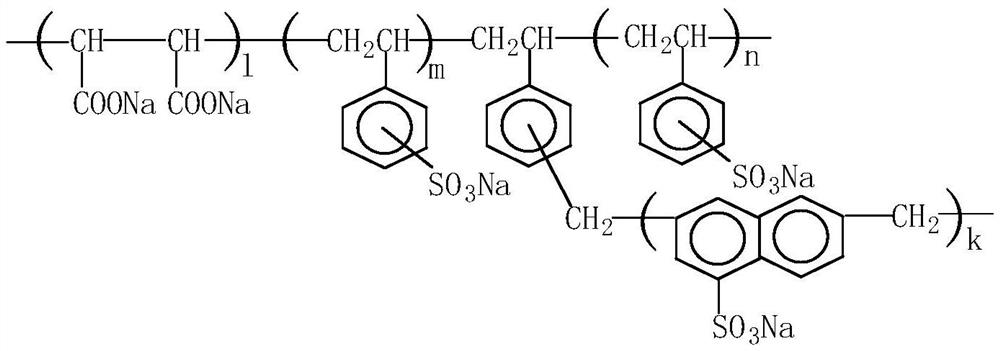

[0038]Dissolve 5 parts by weight of naphthalene at 160°C; carry out sulfonation reaction with 20 parts by weight of sulfuric acid to generate β-naphthalenesulfonic acid; mix the obtained β-naphthalenesulfonic acid with 15 parts by weight of formaldehyde , the styrene of 8 weight parts, the maleic acid of 1 weight part carry out condensation reaction; Carry out cooling again, add the liquid caustic soda of 36 weight parts and the water of 15 weight parts to carry out hydrol...

Embodiment 2

[0042] The present embodiment provides a kind of coal-water slurry, based on the total mass of the coal-water slurry, comprising the following components by weight: 80 parts of coal powder, 20 parts of petroleum coke, 20 parts of water, and the described coal-water slurry also contains additives, The content of the additive is 0.15% of the total mass of coal powder and petroleum coke.

[0043] Present embodiment also provides a kind of preparation method of coal-water slurry, comprises the following steps:

[0044] Dissolve 10 parts by weight of naphthalene at 165°C; carry out sulfonation reaction with 10 parts by weight of sulfuric acid to generate β-naphthalenesulfonic acid; mix the obtained β-naphthalenesulfonic acid with 8 parts by weight of formaldehyde , the styrene of 1 weight part, the maleic acid of 5 weight parts carry out condensation reaction; Carry out cooling again, add the liquid caustic soda of 40 weight parts and the water of 25 weight parts to carry out hydro...

Embodiment 3

[0048] The present embodiment provides a kind of coal-water slurry, based on the total mass of the coal-water slurry, comprising the following components by weight: 80 parts of coal powder, 20 parts of petroleum coke, 20 parts of water, and the described coal-water slurry also contains additives, The content of the additive is 0.15% of the total mass of coal powder and petroleum coke.

[0049] Present embodiment also provides a kind of preparation method of coal-water slurry, comprises the following steps:

[0050] Dissolve 10 parts by weight of naphthalene at 163°C; carry out sulfonation reaction with 20 parts by weight of sulfuric acid to generate β-naphthalenesulfonic acid; dissolve the obtained β-naphthalenesulfonic acid with 15 parts by weight of formaldehyde , the styrene of 5 weight parts, the maleic acid of 5 weight parts carry out condensation reaction; Carry out cooling again, add the liquid caustic soda of 20 weight parts and the water of 25 weight parts to carry ou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap