Demisting device of novel blast furnace gas desulfurization tower and desulfurization tower

The technology of blast furnace gas and mist removal device is applied in the field of blast furnace gas desulfurization, which can solve the problems of affecting blast furnace gas desulfurization effect and increase the resistance in the tower by the mist removal device, so as to improve the utilization rate of internal space, reduce the resistance and improve the desulfurization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

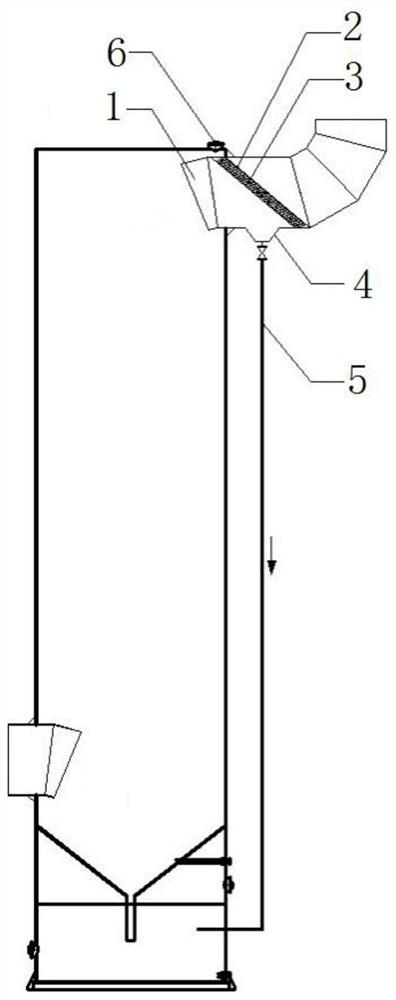

[0025] Such as figure 1 As shown, a new demisting device for a blast furnace gas desulfurization tower includes a gas outlet pipe 1 installed at the gas outlet on the upper part of the tower body, and also includes a defogging material 3, which is obliquely installed in the gas outlet pipe 1, and the upper end It is closer to the tower body than the lower end; the tower body and the air outlet pipe 1 are located at the upper end of the defogging material 3, and a maintenance manhole 6 is opened to facilitate inspection, cleaning and maintenance; all edges of the defogging material 3 are in contact with the inner wall of the air outlet pipe 1 , in order to facilitate installation and maintenance, a layer of steel wire mesh 2 is provided on both sides of the defogging material 3 for positioning and installation. The steel mesh 2 and the inner wall of the air outlet pipe 1 can be welded and fixed. It is more convenient to install the steel mesh 2 , just open the maintenance manho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com