Gate groove construction device and gate groove construction method

A construction device and door slot technology, which is applied in water conservancy projects, sea area engineering, hydroelectric power generation, etc., can solve the problems of inability to cooperate with sliding forms, long construction period, and low efficiency of door slots, so as to shorten the construction period, improve construction efficiency, The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

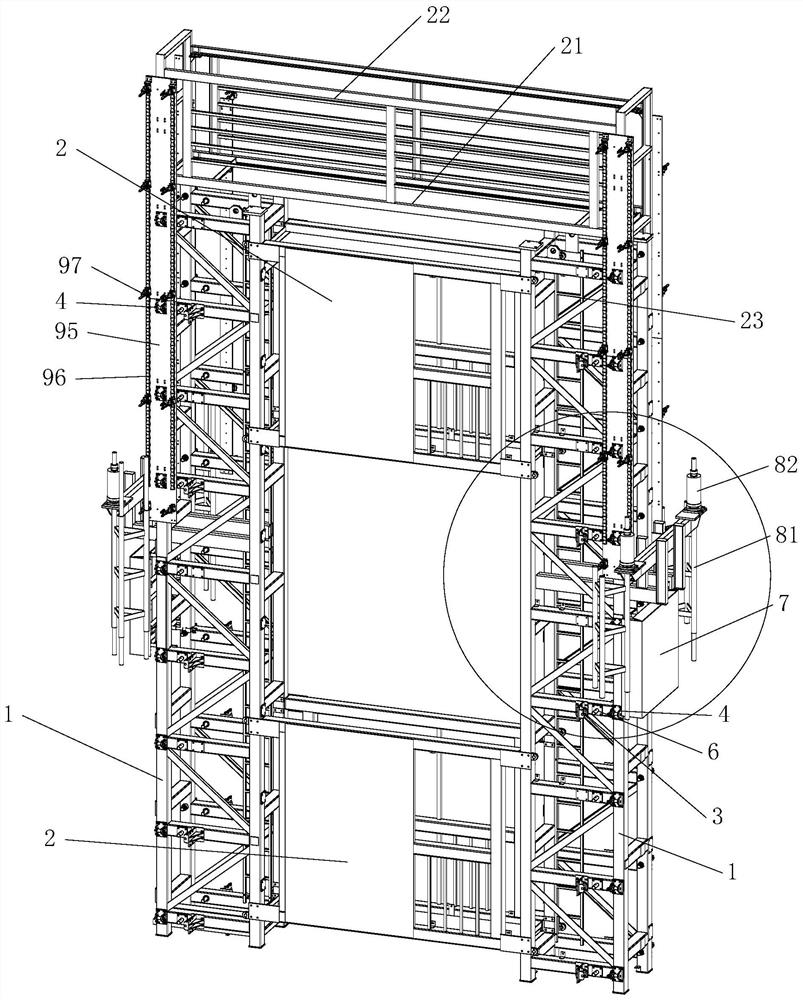

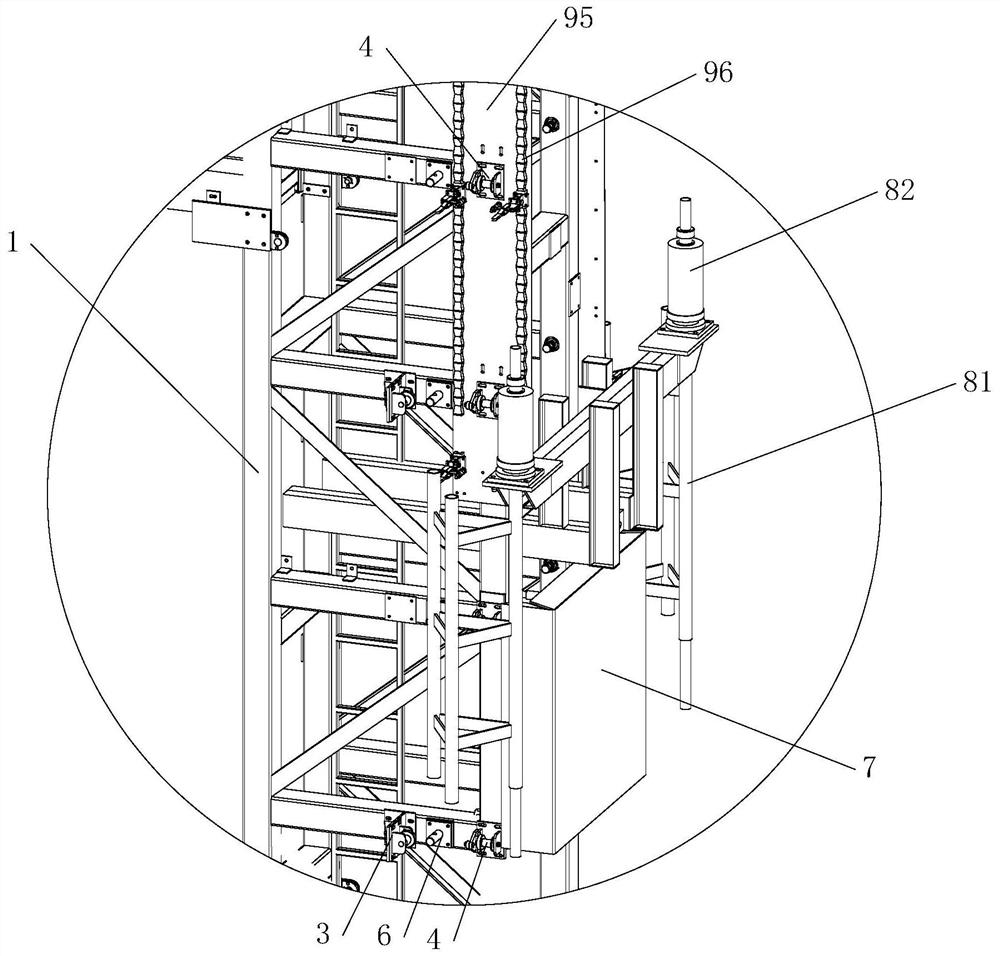

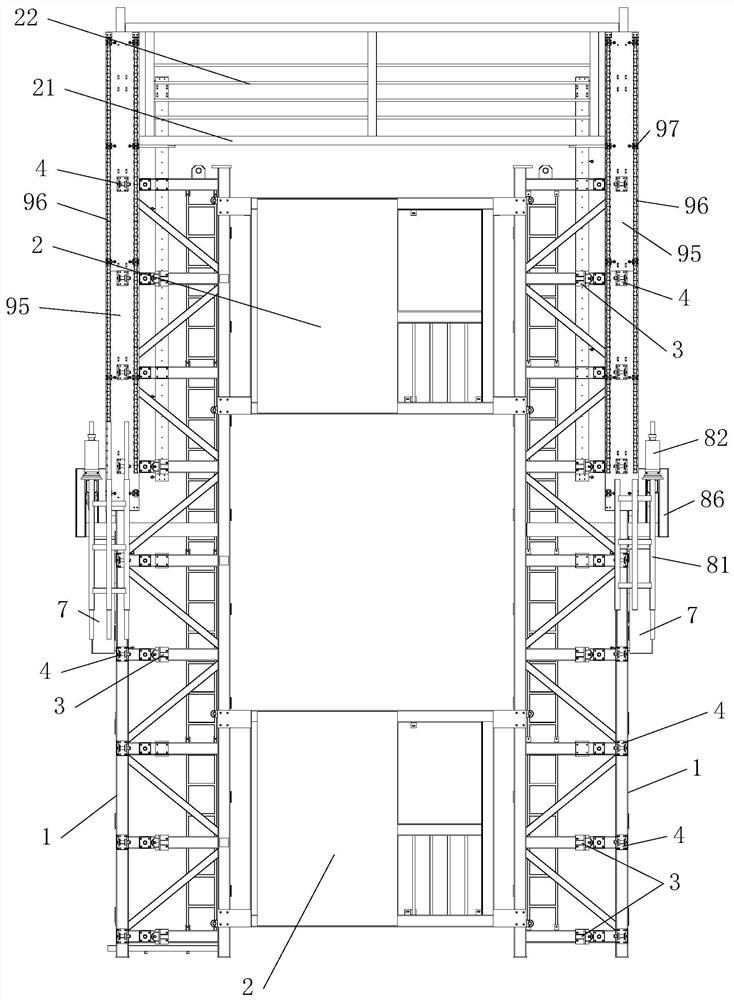

[0108] This embodiment provides a door slot construction device, see Figure 1-7 , including two uprights 1 corresponding to the door slots on both sides and several beam modules 2 connected between the two uprights 1, the sides of the uprights 1 are fixedly connected with several positioning supports, and the positioning supports are used for positioning support Corresponding to the door slot track 11, the positioning support includes a side guide support device 3 and a front support device, the side guide support device 3 is used for sliding contact or rolling contact with the side of the corresponding door slot track 11, and the front support The device is used for sliding contact or rolling contact with the front of the corresponding door slot track 11, and the column 1 is also provided with a fixing device for installing the door slot track 11 to be installed;

[0109] When the column 1 is under the action of lifting force, both the positioning support member and the fixi...

Embodiment 2

[0140] This embodiment provides a door slot construction device, which differs from the door slot construction device described in Embodiment 1 in that when the door slot track 11 to be installed is a material capable of generating magnetic attraction with magnetic components, such as steel structure, the fixing device can adopt a magnetic member, the magnetic member is connected to the column 1 along the longitudinal direction of the column 1, and the magnetic member is used to fix the door slot track 11 . The door slot track 11 is fixed by magnetic attraction to ensure the installation accuracy of the door slot track 11 to be installed. At the same time, under the action of the lifting force, the magnetic member can also slide relative to the door slot track 11 to meet the upward lifting of the door slot construction device. condition. Of course, the door slot track 11 made of steel can also use the compactor 9 in Embodiment 1 as a fixing device.

Embodiment 3

[0142] This embodiment provides a door slot construction device, which differs from the door slot construction device described in Embodiment 1 in that, see Figure 24-25 , the lifting point 84 is not set on the lifting beam 83, and the lifting beam 83 is not connected to the column 1 by a flexible connection such as a steel rope, but a lifting frame 831 is supported on the lifting beam 83, and the lifting Frame 831 is connected with described column 1, and the quantity of lifting frame 831 is determined according to actual situation, and described lifting frame 831 is positioned at the outside of described lifting beam 83 and is provided with lifting frame stopper 832, and described lifting frame stopper 832 has limit position. effect. By placing the lifting frame 831 connected to the column 1 above the lifting beam 83, the lifting frame 831 and the lifting beam 83 are not connected, and the lifting frame 831 is supported by the lifting beam 83. When the lifting beam 83 is li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com