Environment-friendly natural gas boiler with smoke backflow supplementary heating function

A technology for supplementing heating and natural gas, applied in the directions of fluid heaters, steam boilers, water heaters, etc., can solve the problems of wasting water resources, reducing work efficiency, and being unable to use it, avoiding cleaning work, improving filtration effects, and improving practicality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

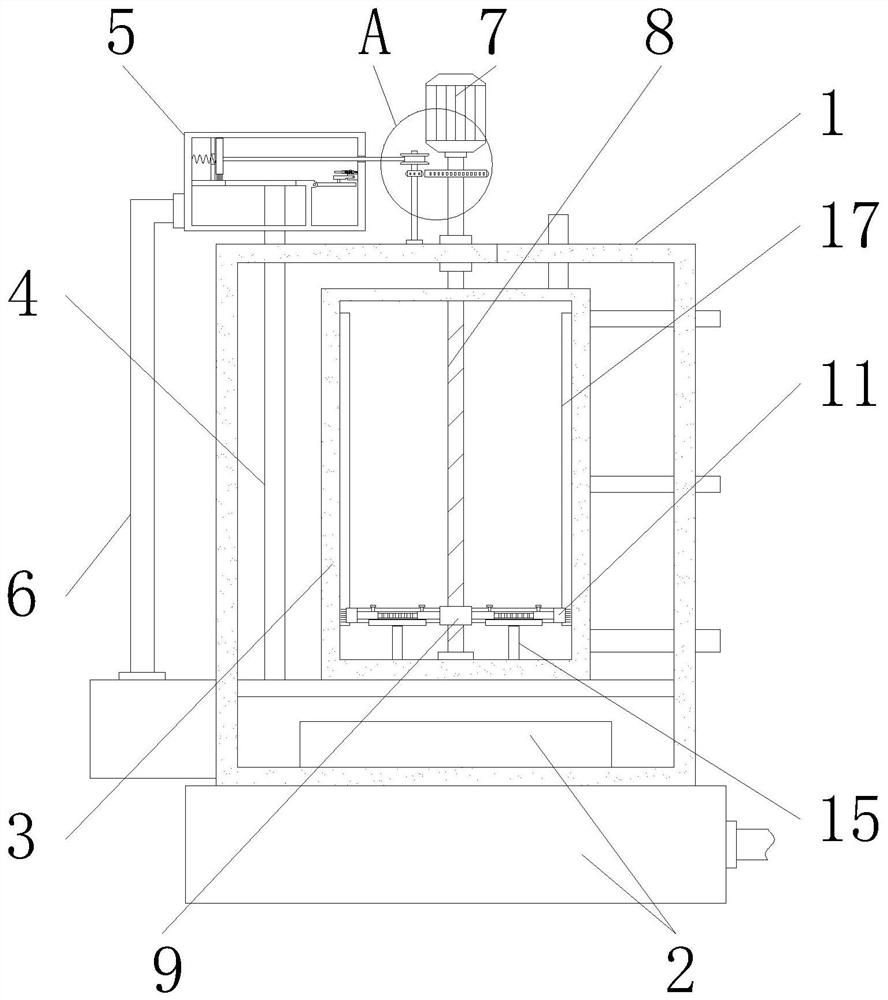

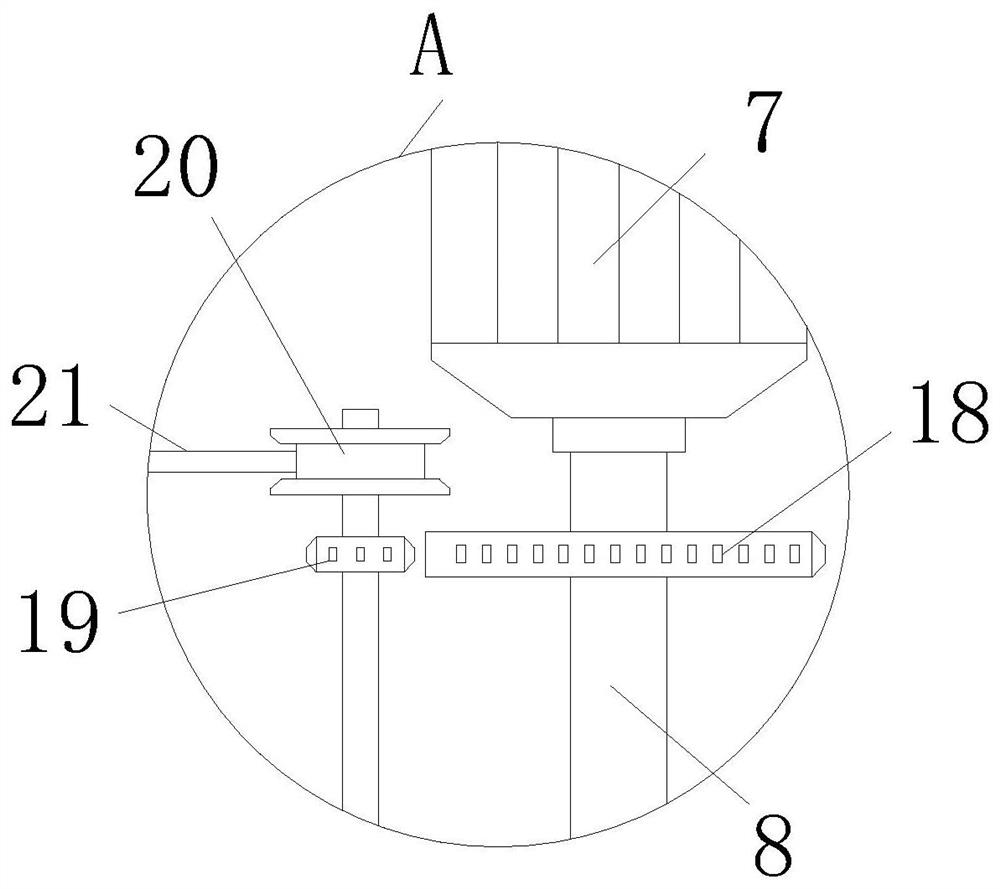

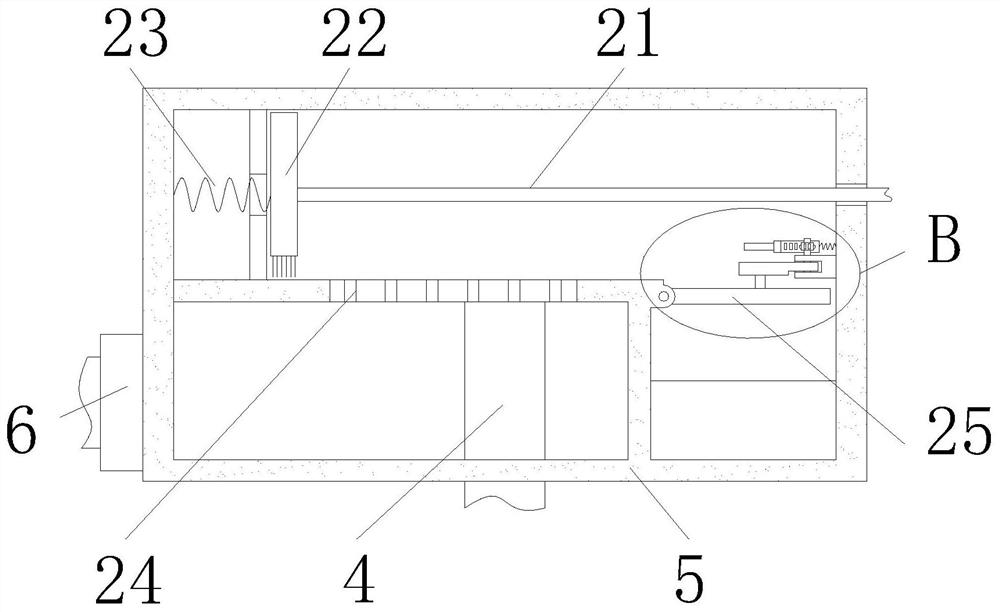

[0029] See Figure 1-8The present invention provides a technical solution: an environmentally friendly natural gas boiler supplemented by a flue gas reflow, including a natural gas boiler body 1, a cleaning mechanism 5, a sliver 10, and a cleaning ring 11, and a natural gas boiler body 1 is provided with a combustion mechanism. 2, and the top of the combustion mechanism 2 is attached to the heating water tank 3, and the left side of the combustion mechanism 2 is connected by the exhaust pipe 4 and the cleaning mechanism 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com