Sulfur dioxide conversion rate automatic sampling system

A sulfur dioxide and automatic sampling technology, applied in sampling, sampling devices, instruments, etc., can solve the problems of low efficiency and large difference in operation proficiency, and achieve the effect of simple operation, high sampling efficiency and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

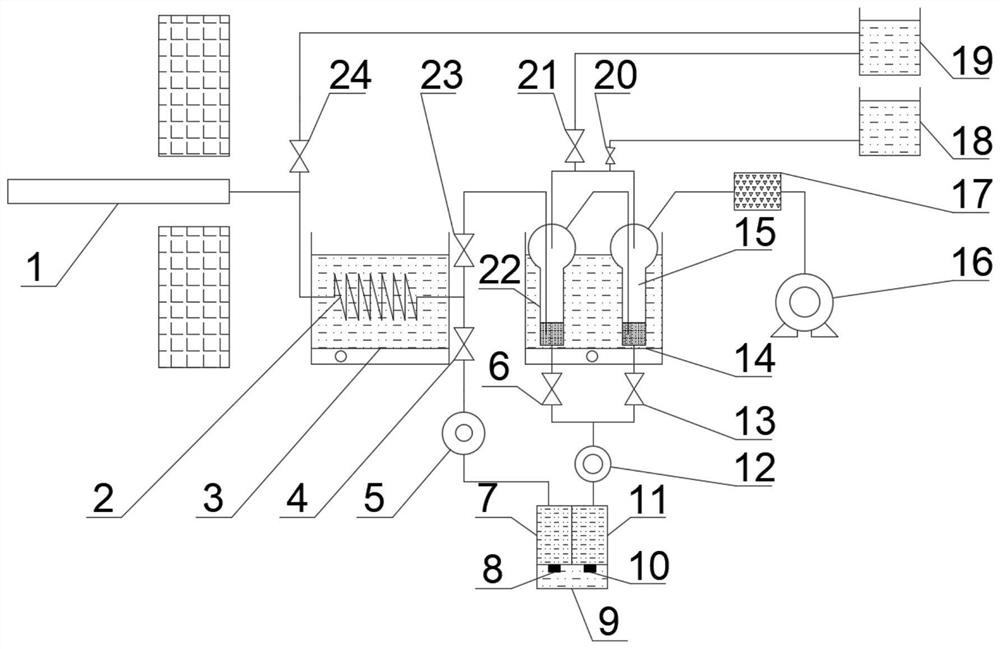

[0017] Such as figure 1 As shown, an automatic sampling system for the conversion rate of sulfur dioxide includes a flue gas sampling tube 1, a quartz spiral tube 2, a heated constant temperature water tank 3, a first solenoid valve 4, a first pumping pump 5, a second solenoid valve 6, and three Sulfur oxide sample tank 7, first cut-off valve 8, waste liquid tank 9, second stop valve 10, sulfur dioxide sample tank 11, second liquid pump 12, third solenoid valve 13, refrigerated constant temperature water tank 14, secondary absorption Bottle 15, flue gas sampling pump 16, dryer 17, hydrogen peroxide tank 18, deionized water tank 19, fourth solenoid valve 20, fifth solenoid valve 21, primary absorption bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com