Method for dynamically monitoring crack tip stress intensity factor

A technology of stress intensity factor and crack tip, which is applied in the measurement of the change force of its optical properties when the material is stressed, the strength characteristics, and the use of stable tension/pressure to test the strength of the material, etc., can solve the quantitative analysis of mechanical damage Difficult, unable to directly and accurately determine the fluorescence boundary and intensity, discontinuous distribution of fluorescence intensity, etc., to achieve the effect of low cost, rapid response, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

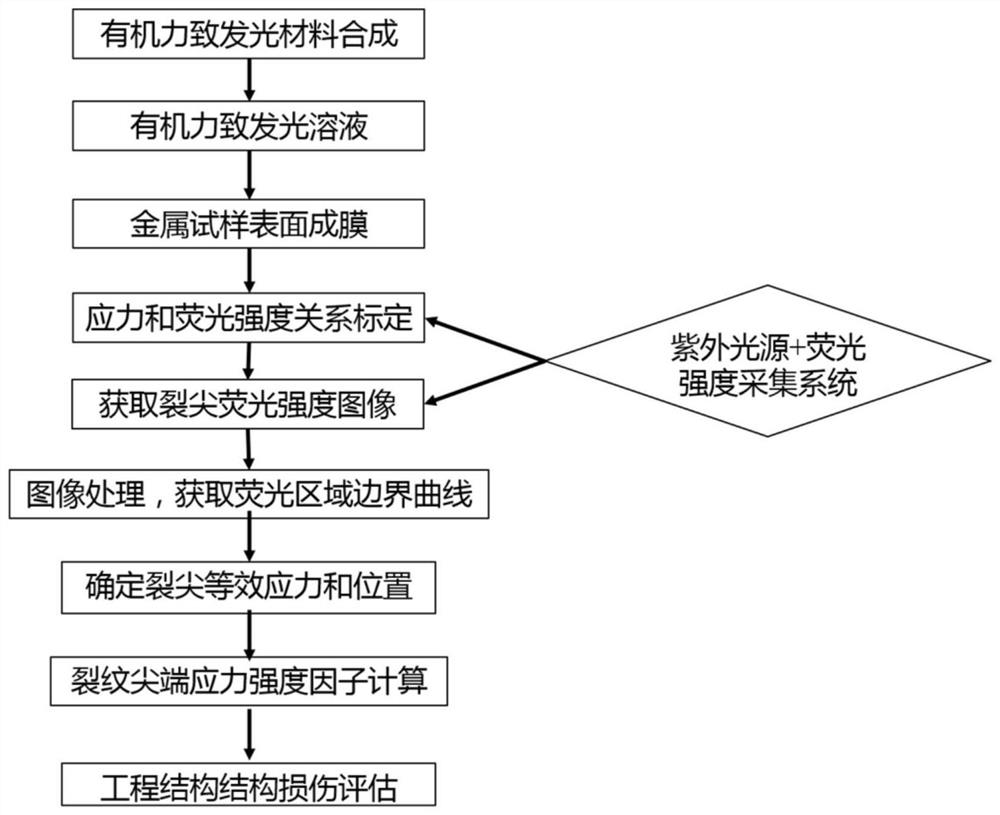

[0075] The specific detection method roadmap is as follows: figure 1 shown.

[0076] (1) Select the organic luminescent material tetranitro-tetraphenylethylene (TPE-4N) as the material; or use chemical methods to synthesize. For the synthesis method, see the Chinese invention patent "Preparation and application of polynitro-substituted tetraphenylethylene compounds" (invention patent application number: CN 201310057959 publication number: CN104003886A).

[0077] (2) Prepare TPE-4N solution, coat the surface of metal components, and heat to form a film.

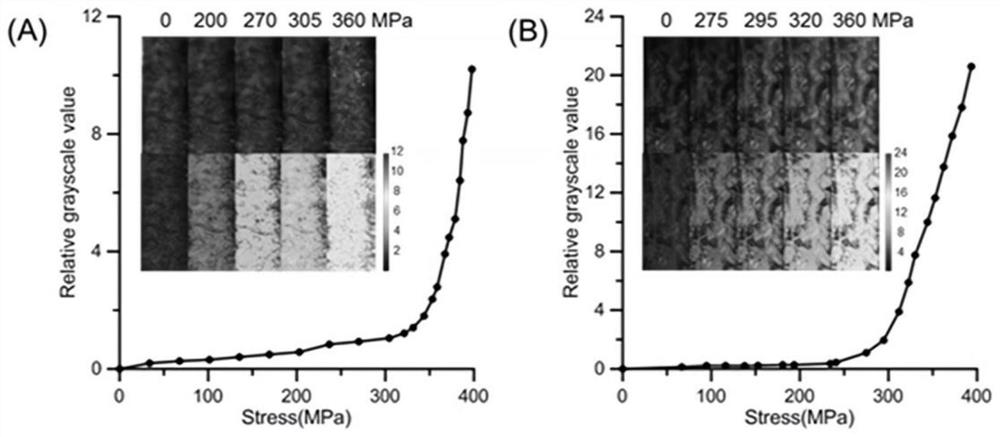

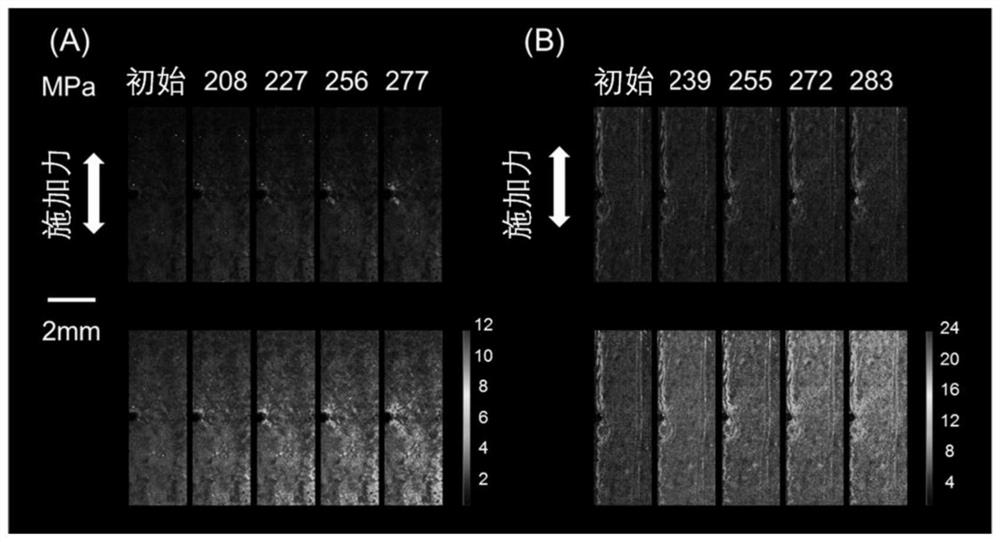

[0078] Sample 1: Dissolve TPE-4N in chloroform to prepare a TPE-4N solution with a concentration of 0.01g / mL, apply the solution on the metal surface with a brush, and heat it at 80°C for 30 minutes with a heat gun to form a film.

[0079] Sample 2: Dissolve TPE-4N in chloroform to prepare a TPE-4N solution with a concentration of 0.03g / mL, apply the solution on the metal surface with a brush, and heat it at 150°C for 2 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com