Wafer test early warning method

A technology for wafer testing and test items, applied in semiconductor/solid-state device testing/measurement, alarms, instruments, etc., can solve the problems of file read and write errors, waste of labor cost and time cost, software stuck, etc. Production efficiency and quality, optimization of design and testing process, effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

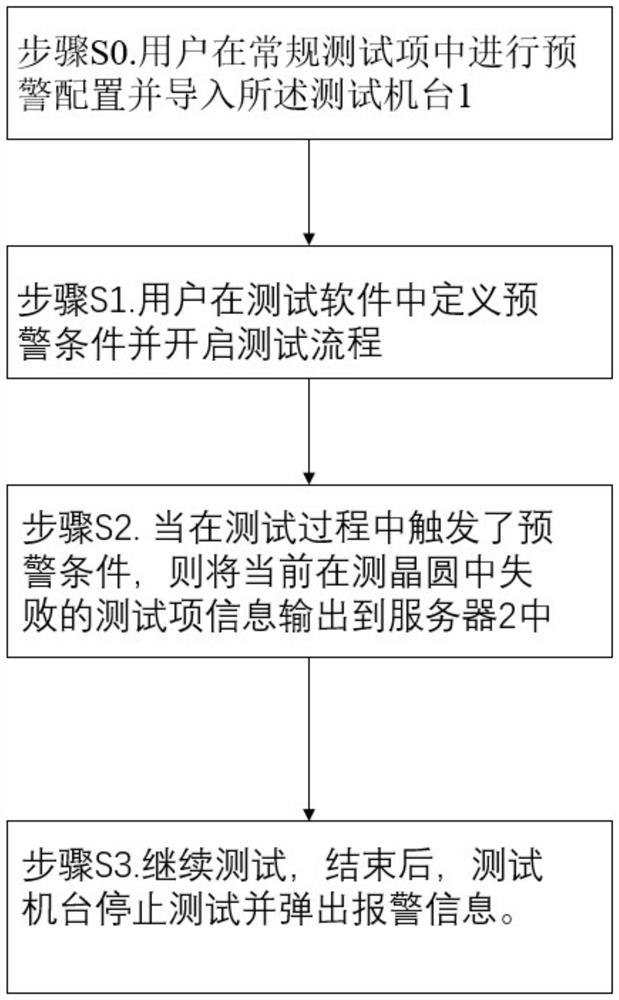

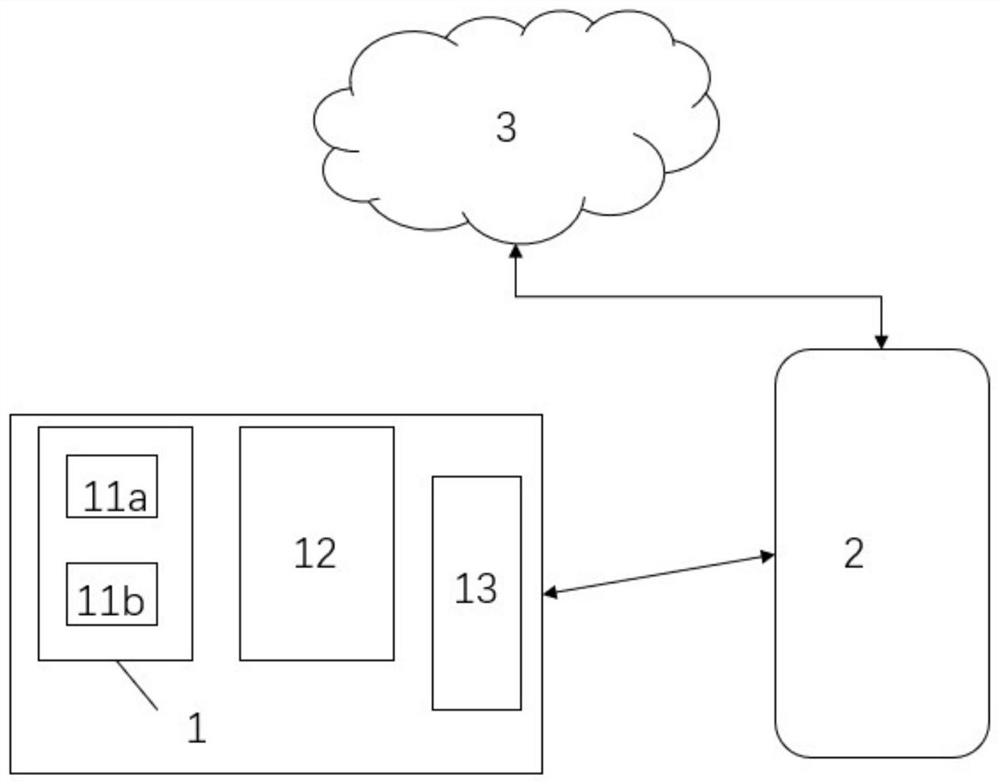

[0024] Such as figure 1 shown, combined with reference figure 2 , in Embodiment 1 of the present invention, the wafer test early warning method specifically includes the following steps: Step S1. The user defines the early warning conditions in the test software and starts the test process; Step S2. The test machine 1 selects the wafer to be tested and starts Test, when an early warning condition is triggered during the test, the test item information that is currently failing in the wafer under test is output to the server 2; Step S3. Continue testing, after the current test of the wafer under test ends, the test The machine stops testing and pops up an alarm message. In this example, if figure 2As shown, the test system includes a test machine 1 and a server 2 , and the test machine 1 includes a test machine 11 , a probe card 12 , and a probe station 13 . The testing machine 11 includes a memory 11a and a processor 11b, and the processor 11b runs the test software on th...

Embodiment 2

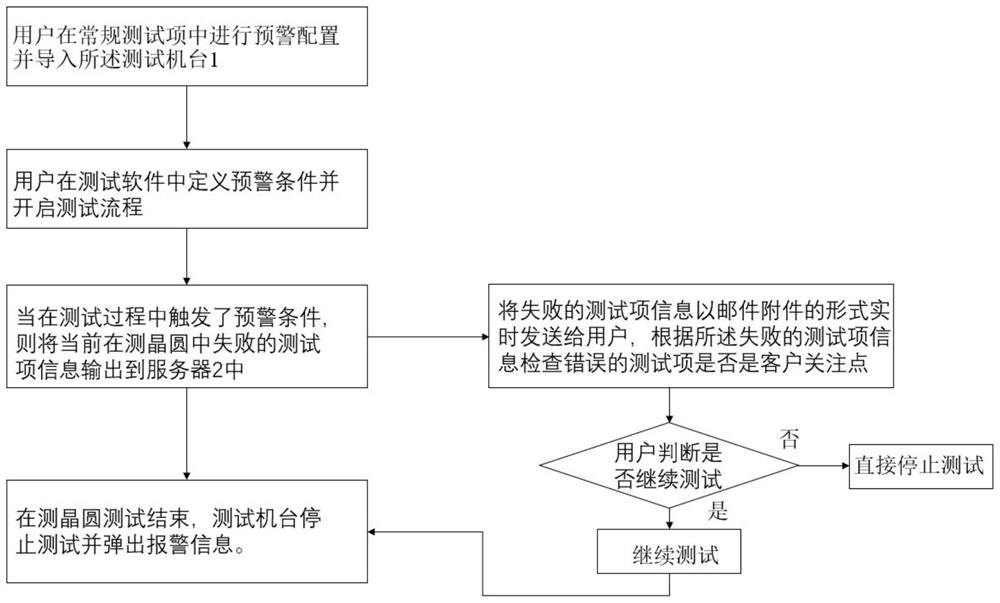

[0027] The difference between this embodiment and the first embodiment is that the server 2 sets a scheduled task plan and loads a script; the script is used to read the information of the failed test items and send it to the user. to combine figure 2 ,Such as image 3 As shown, when the warning condition is triggered, in this embodiment, the script sends the failed test item information to the user in real time in the form of an email attachment. The failed test item information is in the form of a file, which is convenient for users to download and record. In step S2 of this embodiment, the user can check whether the wrong test item is a customer concern according to the failed test item information. A better way is for the user to confirm whether to continue the test process, and the user decides the current error Whether the test needs to be terminated, if not, the test can be continued. In some embodiments, the user receives the failed test item information, but does ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap