Novel carbon group internal cloth type heat conductor

A technology of internal distribution and thermal conductor, which is applied in the direction of modification through conduction and heat transfer, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems that cannot meet the high temperature of electronic devices, and achieve improved heat dissipation effect and improved The effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

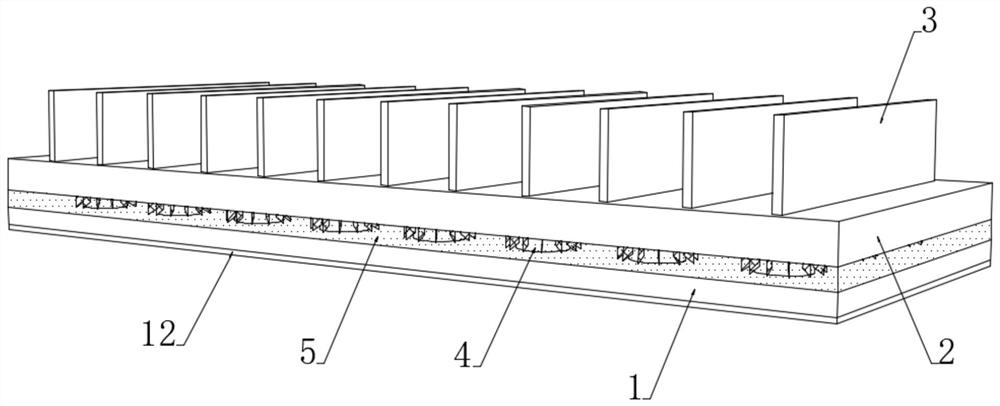

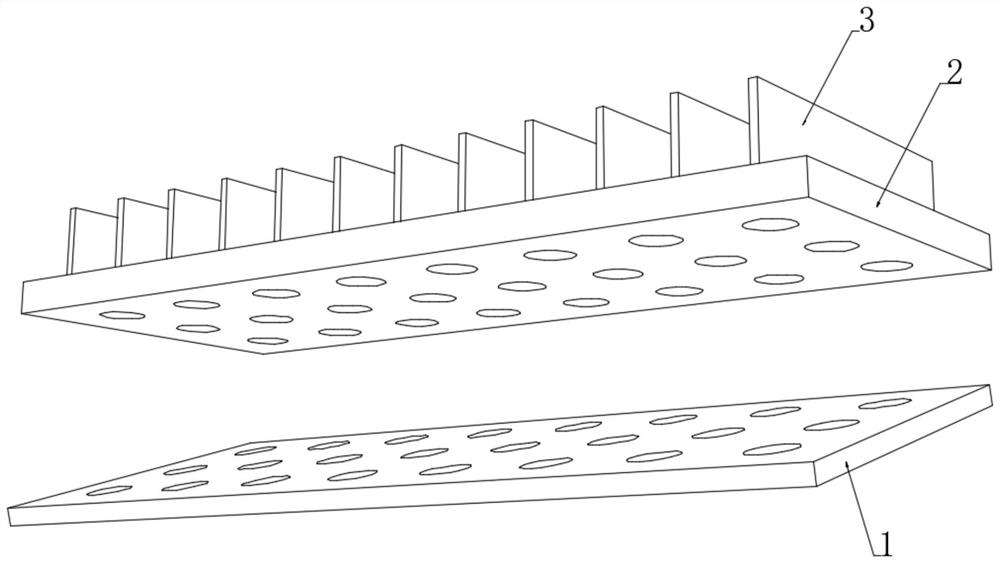

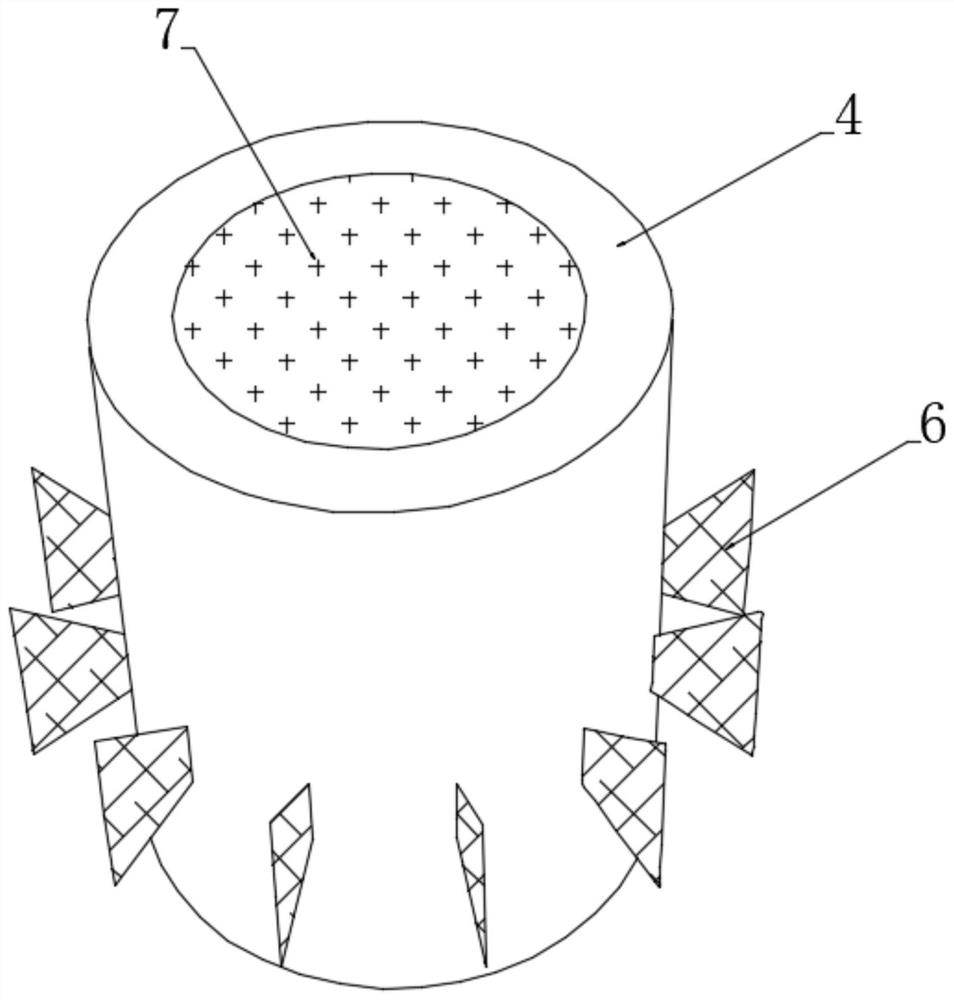

[0041] see Figure 1-3 , a new type of carbon group internal cloth heat conductor, including an inner matrix layer 1 and an outer matrix layer 2, a heat conduction cavity is formed between the inner matrix layer 1 and the outer matrix layer 2, and a plurality of carbon heat conduction tubes 4 are distributed in an array in the heat conduction cavity The upper and lower ends of a plurality of carbon heat conduction tubes 4 are respectively embedded on the opposite side walls of the inner matrix layer 1 and the outer matrix layer 2, and the heat conduction cavity is also filled with an adhesive heat conduction layer filled between the plurality of carbon heat conduction tubes 4 5. The end surface of the inner matrix layer 1 away from the outer matrix layer 2 is attached with a silicone grease bonding layer 12. The inner matrix layer 1 and the outer matrix layer 2 are both made of heat-conducting ceramics and heat-conducting resin. The inner matrix layer 1 and The opposite side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com