A kind of preparation method of machinable diamond/metal matrix composite material

A technology of mechanical processing and composite materials, applied in metal material coating technology, coating, gaseous chemical plating, etc., can solve problems such as processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

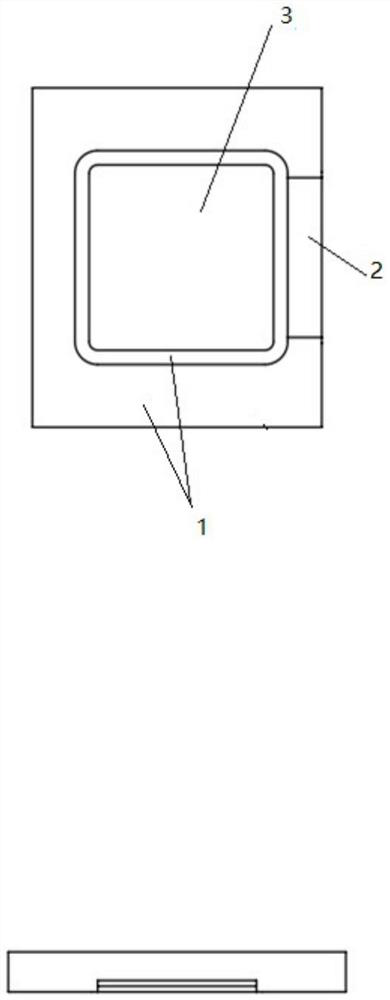

Image

Examples

Embodiment 1

[0040] Preparation of doped diamond particles

[0041] Using single crystal diamond particles with a particle size of 500 μm as the raw material, a polycrystalline diamond transition layer was first deposited on the surface of the diamond particles by chemical deposition, and the mass flow ratio of the atmosphere was CH 4 :H 2 = 2:98, the deposition temperature is 800° C., the growth times are 2 times, and the single deposition time is 10 min to obtain a polycrystalline diamond transition layer with a thickness of 200 nm.

[0042] Then, the doped diamond outer shell layer is grown on the surface of the polycrystalline diamond transition layer by hot wire chemical vapor deposition to obtain doped diamond particles. Deposition process parameters: the distance of the hot wire is 10mm, the thickness of the hot wire is 0.5mm, the growth temperature is 850°C, the deposition pressure is 3KPa, and the thickness of the diamond film is 2μm by controlling the deposition time; during the...

Embodiment 2

[0047] Preparation of doped diamond particles

[0048] Using 400um single crystal diamond particles as the raw material, the polycrystalline diamond transition layer is first deposited on the surface of the diamond particles by chemical deposition. The process is: the mass flow ratio of the incoming atmosphere is CH 4 :H 2 = 2:98, the number of growth is 2 times, and the time of each growth is 20min, and finally a polycrystalline diamond transition layer with a maximum degree of 400nm is obtained.

[0049] Then, a doped diamond outer shell layer is grown on the surface of the polycrystalline diamond transition layer by hot wire chemical vapor deposition to obtain a diamond reinforcement. Deposition process parameters: the distance of the hot wire is 10mm, the thickness of the hot wire is 0.5mm, the growth temperature is 850°C, the deposition pressure is 3KPa, and the thickness of the diamond film is 3μm by controlling the deposition time; during the chemical vapor deposition,...

Embodiment 3

[0054] Preparation of diamond reinforcement

[0055] Using 300um single crystal diamond particles as the raw material, the polycrystalline diamond transition layer is first deposited on the surface of the diamond particles by chemical deposition. The process is: the mass flow ratio of the incoming atmosphere is CH 4 :H 2 = 2:98, the number of growth is 2 times, and the time of each growth is 20min, and finally a polycrystalline diamond transition layer with a maximum degree of 400nm is obtained.

[0056] Then, a doped diamond outer shell layer is grown on the surface of the polycrystalline diamond transition layer by hot wire chemical vapor deposition to obtain a diamond reinforcement. Deposition process parameters: the distance of the hot wire is 10mm, the thickness of the hot wire is 0.5mm, the growth temperature is 850°C, the deposition pressure is 3KPa, and the thickness of the diamond film is 2μm by controlling the deposition time; during the chemical vapor deposition, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com