Salt-free pickled vegetable making method

A production method and technology of hydrochloric acid vegetables, which are applied in the field of food processing, can solve problems such as economic losses of enterprises and waste of resources that have not been fundamentally solved, and achieve the effects of retaining original nutritional components, less nutritional loss, and convenient eating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

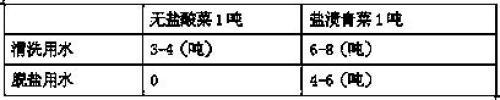

[0032] (1) Vegetable preparation: select fresh green vegetables that are free from pollution, diseases and insect pests, and have no rot and deterioration, remove old tendons and rotten leaves, wash the stems and leaves, and drain most of the water droplets for later use;

[0033] (2) Cleaning and disinfection of the container: Clean the container to be pickled sauerkraut without oil and detergent residue, then rinse it with boiling water, or spray the surface of the container with disinfectant alcohol, and then dry it for later use;

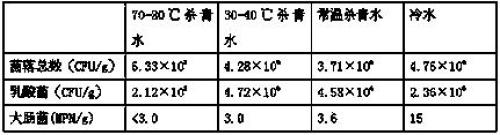

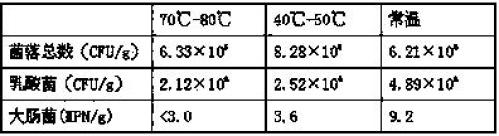

[0034] (3) Vegetable greening: put the selected and washed green vegetables in a boiling water pot and cook for 2 minutes, remove and dry for 1 minute for later use. The drying time should not be too long. The temperature of green vegetables is 70°C, and the greening water is 35°C;

[0035] (4) Fermentation of green vegetables: evenly spread the dried green vegetables in the fermentation container and compact them, pour 4% of the sauerkraut mothe...

Embodiment 2

[0037] (1) Vegetable preparation: select fresh green vegetables that are free from pollution, diseases and insect pests, and have no rot and deterioration, remove old tendons and rotten leaves, wash the stems and leaves, and drain most of the water droplets for later use;

[0038] (2) Cleaning and disinfection of the container: Clean the container to be pickled sauerkraut without oil and detergent residue, then rinse it with boiling water, or spray the surface of the container with disinfectant alcohol, and then dry it for later use;

[0039] (3) Vegetable greening: put the selected and washed green vegetables in a boiling water pot and cook for 3 minutes, take out and let them dry for 2 minutes for later use. The drying time should not be too long. The temperature of green vegetables is 75°C, and the greening water is 40°C;

[0040] (4) Fermentation of green vegetables: evenly spread the dried green vegetables in the fermentation container and compact them, pour 6% of the sauerk...

Embodiment 3

[0042] (1) Vegetable preparation: select fresh green vegetables that are free from pollution, pests and diseases, and have no rot and deterioration, remove old tendons and rotten leaves, wash the stems and leaves, and drain most of the water droplets for later use;

[0043] (2) Cleaning and disinfection of the container: Clean the container to be pickled sauerkraut without oil and detergent residue, then rinse it with boiling water, or spray the surface of the container with disinfectant alcohol, and then dry it for later use;

[0044] (3) Vegetable greening: put the selected and washed green vegetables in a boiling water pot and cook for 3 minutes, remove and dry for 1 minute for later use. The drying time should not be too long. The temperature of the green vegetables is 80°C, and the greening water is 30°C;

[0045] (4) Fermentation of green vegetables: evenly spread the dried green vegetables in the fermentation container and compact them, pour 5% of the first-made sauerkra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com