Steel rail utilization rate increasing method based on heel end precision forging line

A technology of utilization and precision forging, applied in forging furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of uncontrollable static positioning of rail forging and inability to realize pressing operations, so as to improve extreme operating conditions and improve the company's The effect of operating efficiency, cost reduction and efficiency increase promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

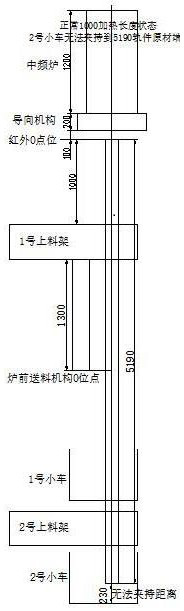

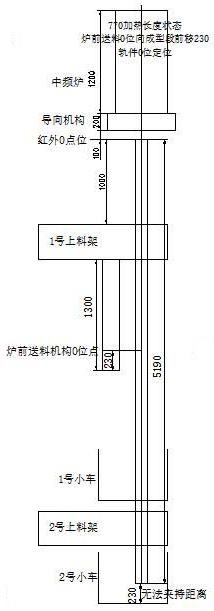

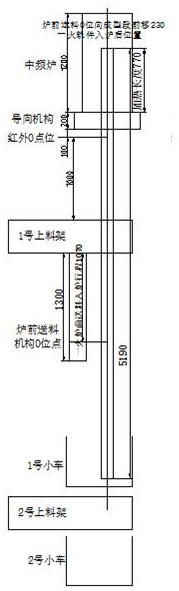

[0041] Attached below Figure 1-12 Specific examples of the present invention are described.

[0042] The following examples facilitate a better understanding of the present invention, but do not limit the present invention. The following embodiments are only some of the embodiments of the present invention, but not all of them. The components and materials used in the following examples are commercially available unless otherwise specified. The equipment used in the following examples is existing equipment.

[0043] A method for improving the utilization rate of rails based on a heel-end precision forging line, characterized in that it includes the following methods:

[0044] (Such as figure 1 Shown) Method 1. Adjust the 0 o’clock position of the feeding mechanism in front of the furnace towards the forming section, and move the 0 o’clock position of the feeding mechanism in front of the furnace from the farthest stroke to the forming section by Lmm; the heating length is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com