A sludge anaerobic digestion method based on combined pretreatment of thermal hydrolysis and chemical conditioning

A technology of anaerobic digestion and thermal hydrolysis, applied in pyrolysis sludge treatment, dewatering/drying/concentrating sludge treatment, biological sludge treatment, etc., which can solve the requirements of high energy consumption, difficulty in achieving energy gains and operating conditions. Advanced problems, to achieve the effect of low energy consumption, harmless, and strong economical applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

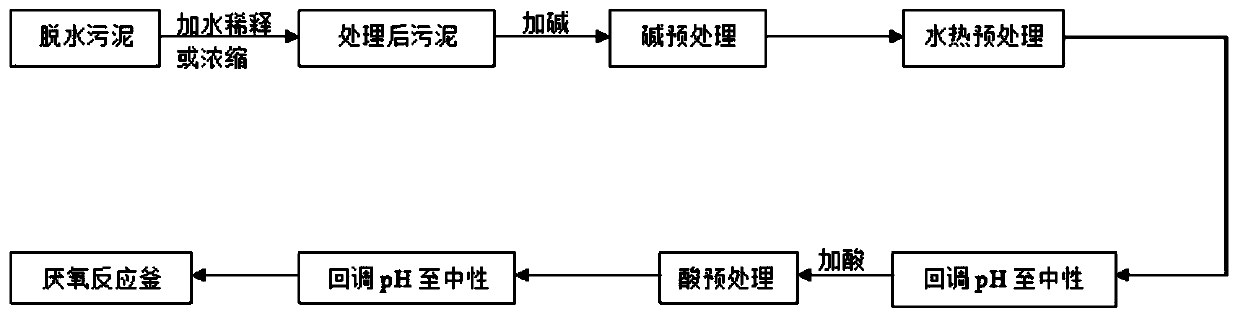

Method used

Image

Examples

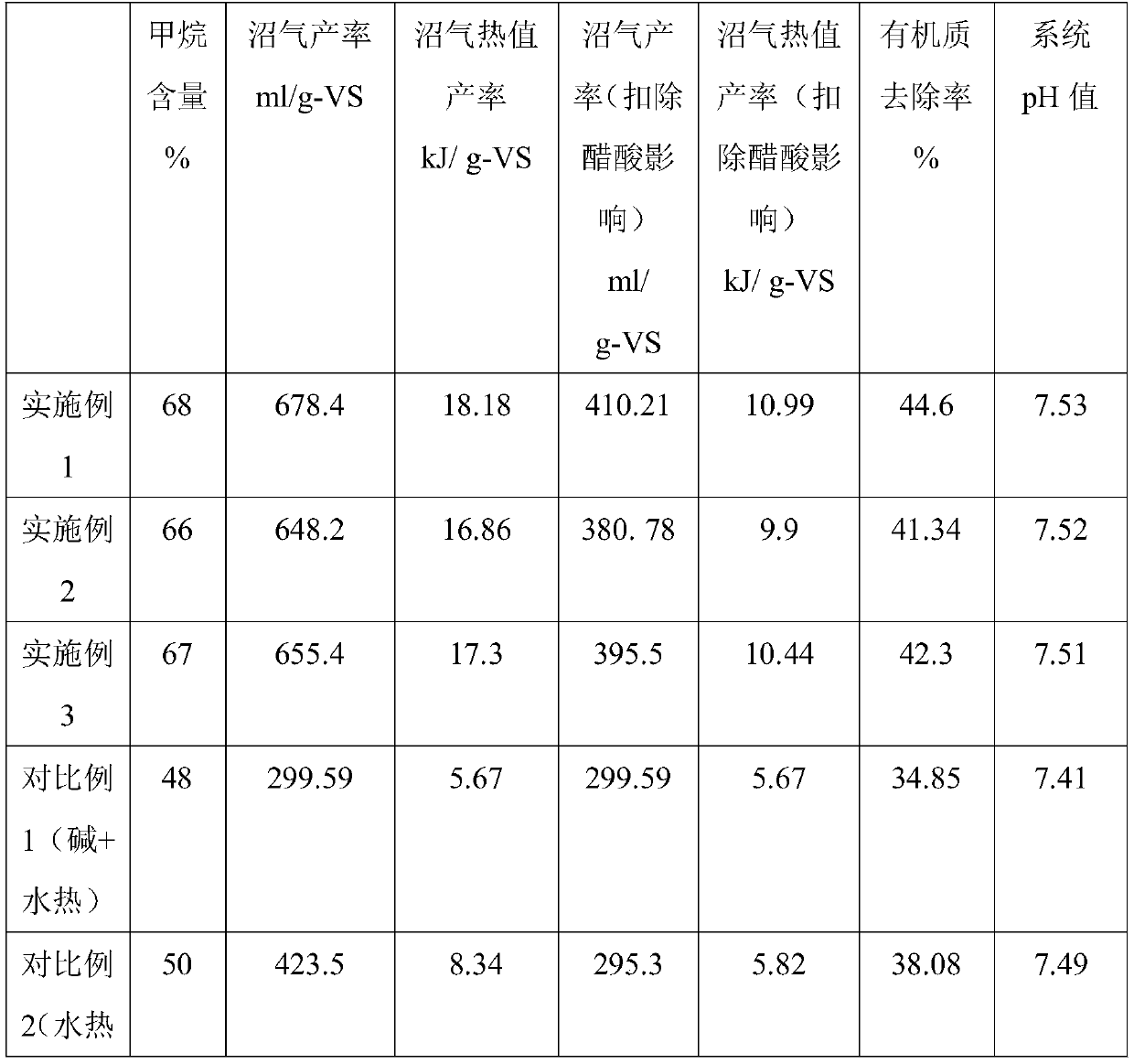

Embodiment 1

[0029] Take 250 g of dewatered sludge (84% moisture content) from a sewage treatment plant in Nanjing and put it into a stirring tank, stir at low speed, add 250 g of mixed water of tap water and reused water, and obtain 500 g of sludge with a solid content of 8%. Then add 1mol / L sodium hydroxide to the stirring tank until the pH meter in the tank shows a pH value of 10, and let it stand for 20 hours. Then the alkali pretreated sludge is pumped into a high-temperature and high-pressure reactor, and thermally hydrolyzed at 80°C for 120 minutes. After thermally hydrolyzed, the sludge is cooled to 55°C through a heat exchanger, and the energy is recovered after heat exchange. In the thermal hydrolysis stage, enter the stirring tank, add 1mol / L hydrochloric acid to make the sludge neutral, add 1mol / L acetic acid to make the sludge pH 4, then add 1mol / L sodium hydroxide until the system is in the middle Sex. Before anaerobic digestion, 4.5L of sludge (pH 7.4, alkalinity (calculated...

Embodiment 2

[0031] Take 105.26g of dewatered sludge (water content of 81%) from a sewage treatment plant in Yixing and put it into a stirring tank, stir at low speed, and add 228.07g of tap water to obtain 333.33g of sludge with a solid content of 6%. Then add 5mol / L calcium hydroxide to the stirring tank until the pH meter in the tank shows a pH value of 11, and let it stand for 24 hours. Then pump the alkali-pretreated sludge into a high-temperature and high-pressure reactor, and thermally hydrolyze it at 117.9°C for 30 minutes. After thermally hydrolyzed, the sludge is cooled to 50°C through a heat exchanger, and the energy is recovered after heat exchange. At the thermal hydrolysis stage, enter the stirring tank, add 2mol / L nitric acid to make the sludge neutral, add 3mol / L citric acid to make the sludge pH 5, and then add 2mol / L calcium hydroxide until the system is neutral. Before anaerobic digestion, add 4.67L of sludge (pH 7.4, alkalinity (calculated as bicarbonate) 2800mg / L, ammo...

Embodiment 3

[0033] Take the remaining sludge from a sewage treatment plant in Nanjing (with a water content of 99%) and concentrate it with a solid content of 9%. Take 250g of sludge with a solid content of 9% in a stirred tank for pretreatment. First, add 10 mol / L potassium hydroxide to the stirred tank until the pH meter in the tank shows a pH of 12, and let it stand for 30 hours. Then the alkali pretreated sludge is pumped into a high-temperature and high-pressure reactor, and thermally hydrolyzed at 100°C for 240 minutes. After the thermally hydrolyzed sludge is cooled to 60°C through a heat exchanger, the energy is recovered after heat exchange. In the thermal hydrolysis stage, enter the stirring tank, add 5mol / L sulfuric acid to make the sludge neutral, add 6mol / L malic acid to make the sludge pH 5, and then add 5mol / L potassium hydroxide until the system is neutral. Before anaerobic digestion, add 4.75L of sludge (pH 7.4, alkalinity (calculated as bicarbonate) of 3000mg / L, and ammo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com