Method for improving recovery efficiency of phosphorus in sludge and promoting anaerobic digestion

An anaerobic digestion and phosphorus recovery technology, applied in chemical instruments and methods, phosphorus compounds, sludge treatment, etc., can solve the problems of low release, difficult release, adverse effects of equipment, etc., to improve recovery efficiency, improve purity, Conducive to the effect of transportation and post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] (1) Take the remaining sludge from the secondary sedimentation tank of the urban sewage treatment plant, centrifuge it through a centrifuge at 1500r / min, and centrifuge it at room temperature for 5 minutes, so that its moisture content will be about 95% (residual sludge characteristics: TP: 520~734.1mg / L, IP: 416.1~458.1mg / L, TCOD: 44707~45180mg / L).

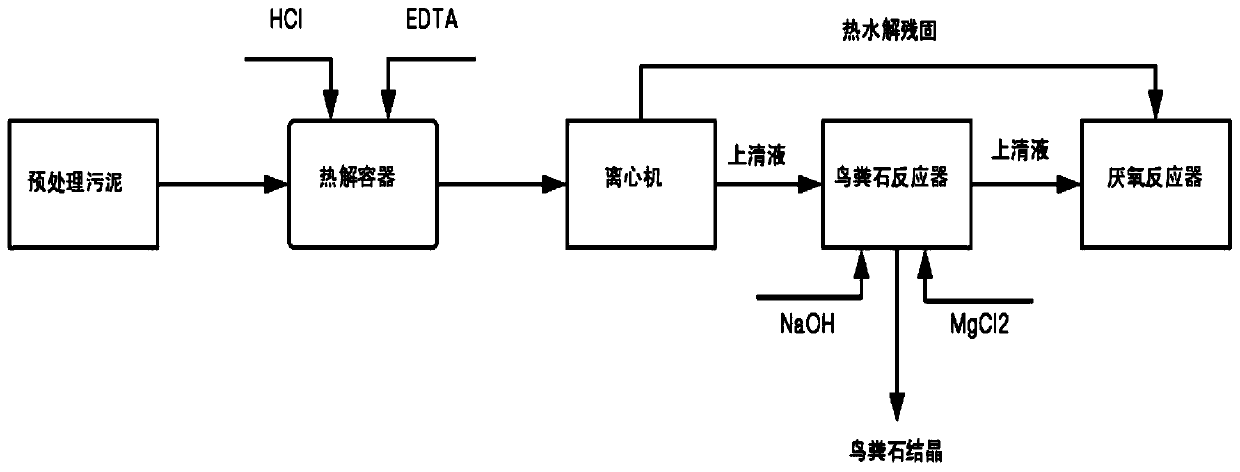

[0044] (2) if figure 1 As shown, the excess sludge with a moisture content of 95% obtained from pretreatment is added to the low-temperature thermal hydrolysis reactor, and the pH of the sludge is adjusted to 3.9 with 1mol / L HCl solution, the temperature is 62°C, and the EDTA concentration is 9.2mmol / L. Under low-temperature thermal hydrolysis reaction for 1 h. After the reaction, centrifuge at a speed of 3000r / min for 5min to separate the solid and liquid to obtain the supernatant and the thermally hydrolyzed residual solid. The concentration of phosphorus, orthophosphate, ammonia nitrogen, and SCOD in the supernatant c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com