Preparation method of graphene nanoribbons

A graphene nanoribbon and graphene film technology, applied in the field of graphene nanoribbon preparation, can solve the problems of complex process, limited resolution and high cost, and achieve the effects of simple process operation, breakthrough of application bottleneck and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention more clear, the principle and experimental process of the present invention will be further described below in conjunction with the accompanying drawings.

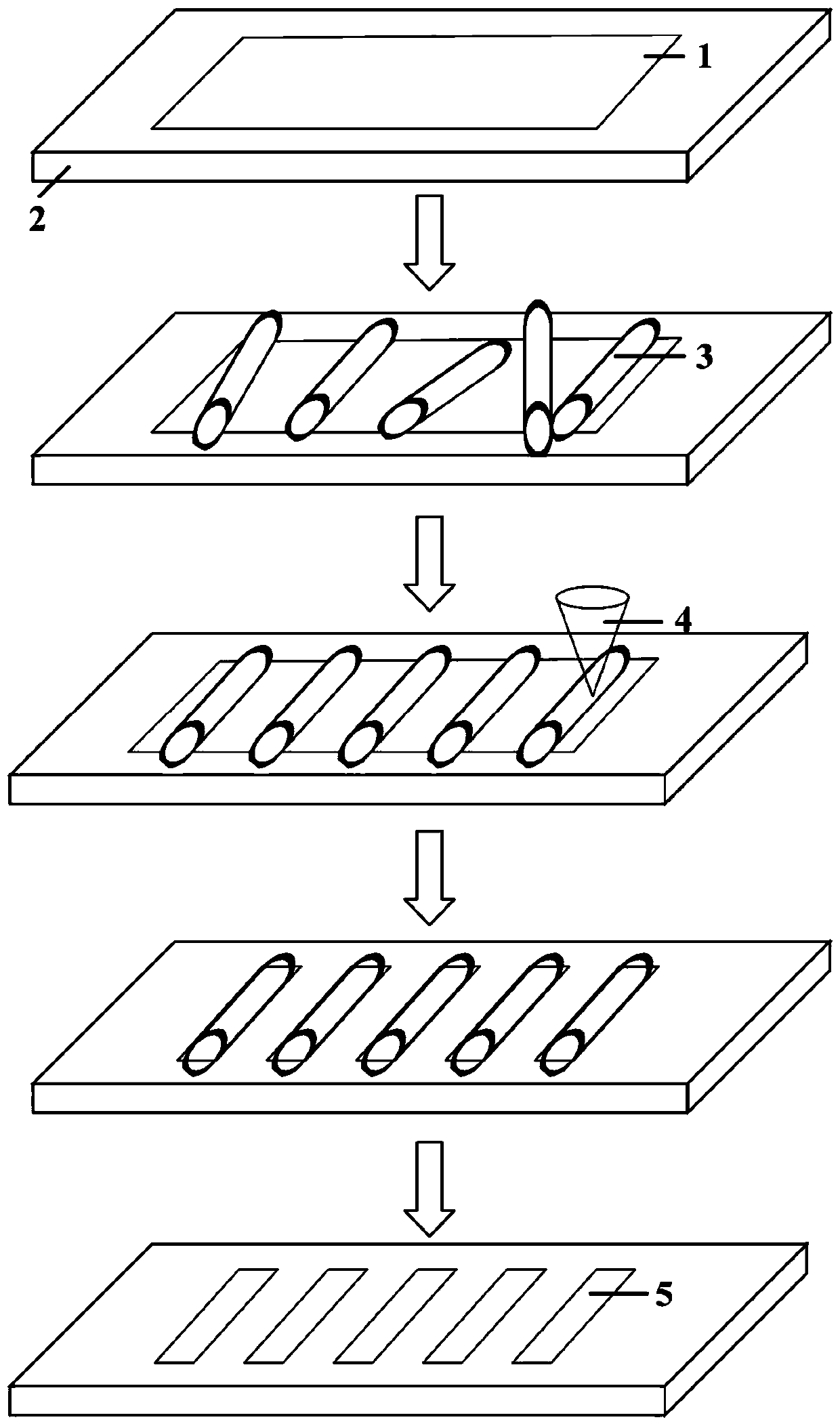

[0027] Such as figure 1 Shown, the invention provides a kind of preparation method of graphene nanobelt, comprises the following steps:

[0028] 1) Preparation of single-crystal single-layer graphene film 1 and transfer to SiO 2 on substrate 2;

[0029] 2) preparing nanowires 3 with a diameter of 5-10nm, and randomly dispersing them on the surface of the graphene film;

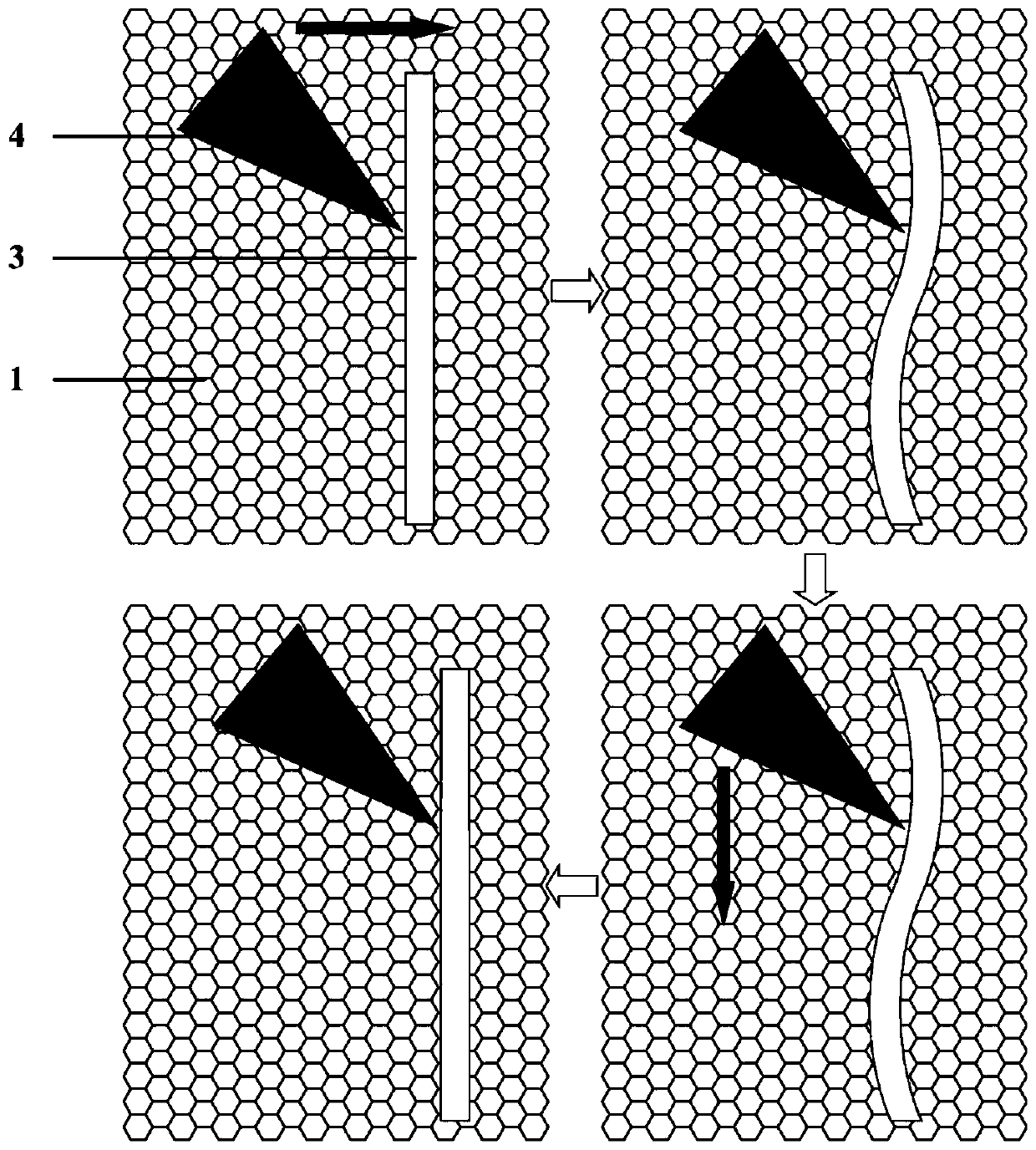

[0030] 3) Manipulating the above-mentioned nanowires through the microprobe 4 so that they are neatly arranged into an array structure;

[0031] 4) Using the nanowire array structure as a masking layer, remove the graphene 3 in areas other than the nanowires by etching;

[0032] 5) removing the nanowires on the substrate to obtain a graphene nanoribbon array...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com