Forming method of short fiber reinforced thermoplastic composite material corrugated structure

A technology of short fiber reinforcement and composite materials, which is applied in the molding field of short fiber reinforced thermoplastic composite corrugated structures, and can solve the problems of poor mechanical properties of foam sandwich structures, poor bonding force between skin and foam, and poor conformability of foam, etc. Achieve the effects of convenient processing, improved compressive and bending resistance, and strong conformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

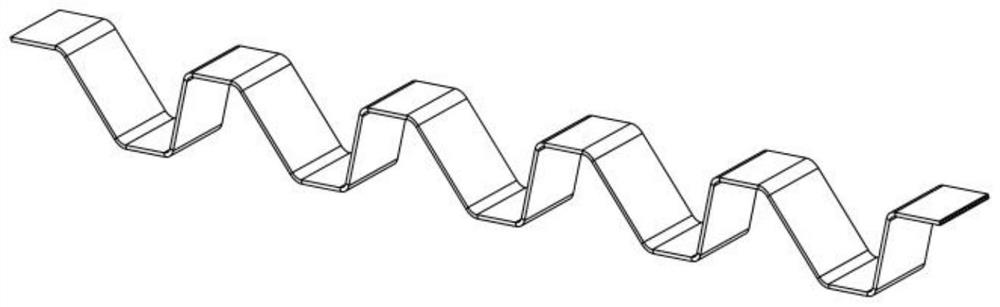

[0021] like figure 1 As shown, the corrugated structure of the short fiber reinforced thermoplastic composite material of the present invention includes fibers and a resin matrix, the resin matrix covers the fibers, and the corrugated structure is a continuous trapezoidal waveform.

[0022] The fiber is one or a mixture of carbon fiber, glass fiber, aramid fiber and basalt fiber.

[0023] The resin matrix is one of PP, PE, PA, PPS and PEEK plastics, that is, the resin matrix can be polypropylene, polyethylene, nylon, polyphenylene sulfide, polyether ether ketone and the like.

[0024] In the present invention, the corrugated material is designed as a trapezoidal waveform, which has higher rigidity and other mechanical properties than traditional core materials (balsa wood, honeycomb and foam, etc.). In addition, by setting reinforcing fibers, its com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com