Fuel conveying equipment with temperature measuring function and based on coal-fired power generation technology

A temperature measurement function and fuel conveying technology, which is applied to conveyors, conveyor objects, conveyor control devices, etc. Ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

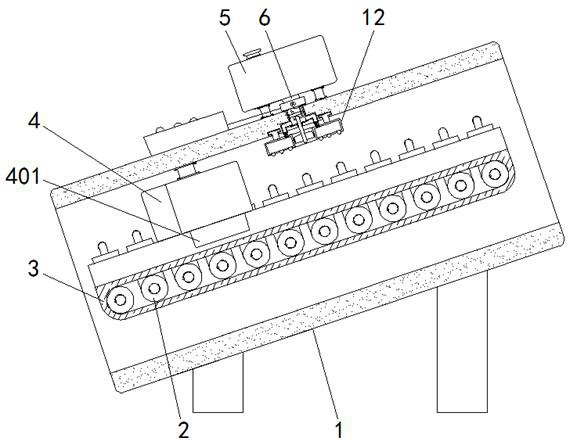

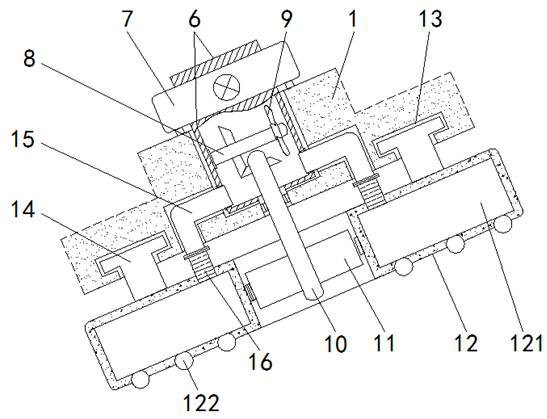

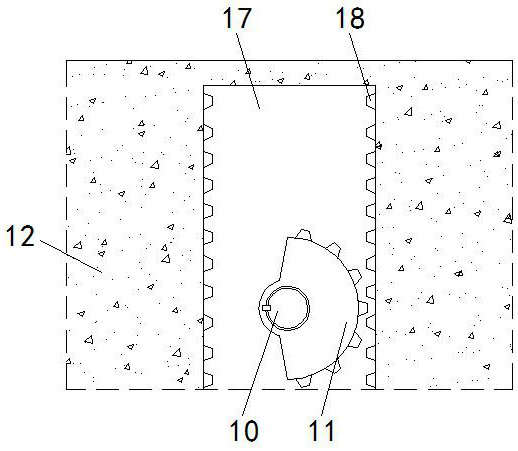

[0029] See Figure 1-8 The present invention provides a technical solution: a fuel delivery apparatus having a temperature-warmed coal-fired power generation technique comprising a housing main body 1, a conveying roller 2, a conveying belt 3, a guide frame 4, a guide block 401, The bump 402, the heat conductive rod 403, the water storage chamber 5, the main connecting tube 6, the water pump 7, the crossbar 8, the seaflore 9, the vertical rod 10, the sector gear 11, the drainage frame 12, the temporary storage chamber 121, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com