A kind of preparation method of conductive polymer composite material

A technology of conductive polymers and polymer materials, applied in the field of preparation of polymer composite materials, can solve the problems of low conductivity and poor mechanical properties of pure solid-state filling, and achieve easy performance regulation, simple processing and molding, and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

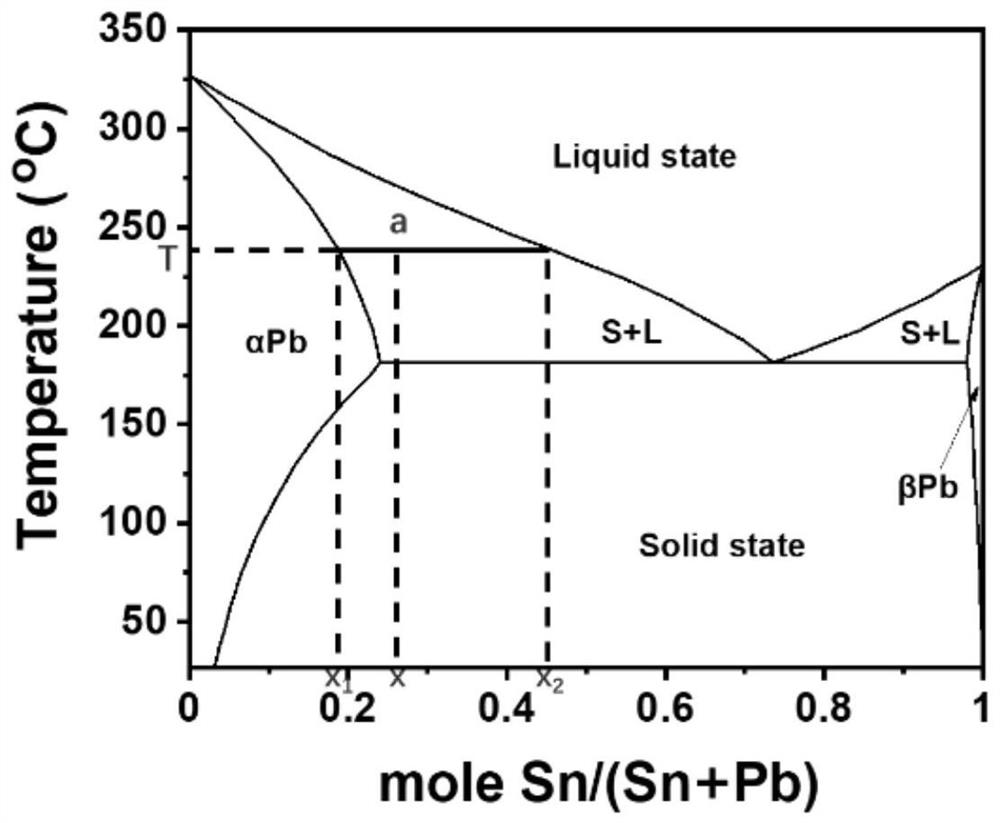

Image

Examples

Embodiment 1

[0041] The invention discloses a preparation method of a conductive polymer composite material, comprising the following steps:

[0042] (1) according to the proportioning in table 1, take by weighing the tin elemental powder, lead elemental powder, polyethylene, antioxidant 264, tribasic lead sulfate that particle diameter is 5 microns respectively;

[0043] (2) Roughly mix lead elemental powder and tin elemental powder with polyethylene, antioxidant 264 and tribasic lead sulfate;

[0044] (3) The above-mentioned mixture was molded by applying a pressure of 6 MPa at 200° C. by a hot-press molding method.

Embodiment 2

[0046] The basic steps are the same as in Example 1, and the specific parameters are shown in Table 1.

Embodiment 3

[0048] The basic steps are the same as in Example 1, and the specific parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com