Durable liquid silica gel

A liquid silicone, durable technology, used in recycling technology, mechanical material recycling, plastic recycling, etc., can solve problems such as debris blowing to the side, inability to complete cleaning, product damage, etc., to improve smoothness, improve die casting quality, The effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A durable liquid silica gel, its raw materials include A-component rubber and B-component rubber, the A-component rubber includes: 80-100 parts of hydroxyl-terminated polysiloxane, 5-parts of vinyl-terminated silicone oil 20 parts, 0.3-1.2 parts of platinum catalyst; the B component rubber includes: 80-100 parts of hydroxyl-terminated polysiloxane, 5-15 parts of tetraethyl orthosilicate, 2.5-4.5 parts of polyethylene glycol, ammonia 4-7 parts of propyltriethoxysilane.

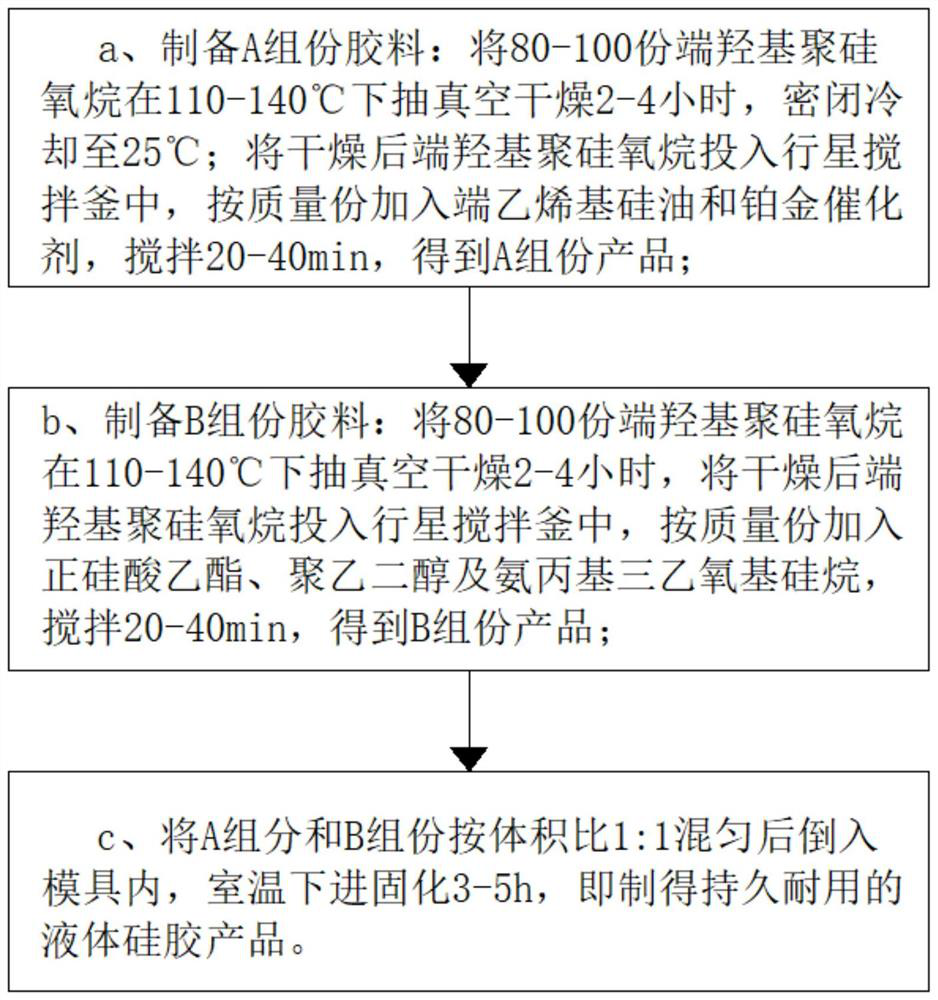

[0050] Based on the above formula and process, the present invention also provides a preparation method of durable liquid silica gel, such as figure 1 shown, including the following steps:

[0051] a. Preparation of component A compound: vacuum-dry 90 parts of hydroxyl-terminated polysiloxane at 120°C for 3 hours, airtightly cool to 25°C; put the dried hydroxyl-terminated polysiloxane into a planetary stirring tank, Add terminal vinyl silicone oil and platinum catalyst in parts by mass, and stir for 30...

Embodiment 2

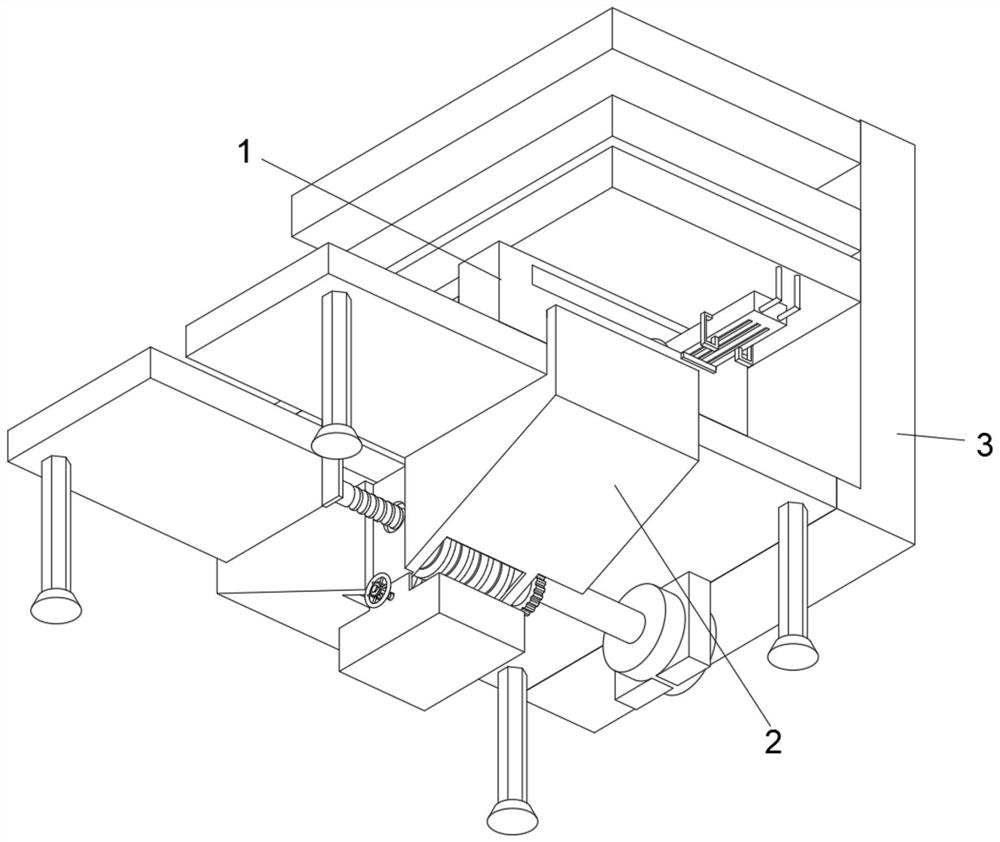

[0065] On the basis of Example 1, such as Figure 11As shown, the support horizontal plate 9 also includes a rolling wheel 41 and a rotating rod 42 , the rotating rod 42 is rotationally connected to the inside of the supporting horizontal plate 9 symmetrically and equidistantly, and the rolling wheel 41 is symmetrically and fixedly connected to the rotating rod 42 .

[0066] When this embodiment is in use, it is connected to the inner bottom end of the support horizontal plate 9 through the symmetrical rotation of the rotating rod 42, and the rolling wheel 41 is symmetrically fixedly connected between the rotating rod 42 and the rotating rod 42, and the rolling wheel 41 is connected to the supporting workbench. 40 surface contact can improve the smoothness of the support horizontal plate 9 when moving, and greatly shorten the time consumed by the support horizontal plate 9 when moving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com