Continuous pad dyeing method for braids

A continuous and pad dyeing technology, which is applied in dyeing, textiles and papermaking, can solve the problems of long dyeing time, high dyeing quality, and low efficiency, and achieve the effect of prolonging the dipping time, increasing the number of dipping times, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

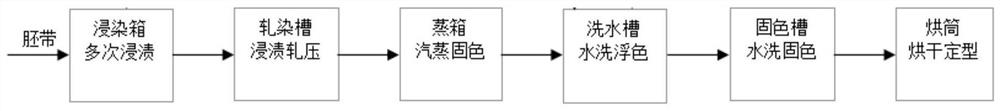

[0026] as attached figure 1 As shown, the invention provides a kind of webbing continuous pad dyeing method, comprises the following steps:

[0027] Prepare the dipping box and the padding box. The dipping box and the padding box are filled with dye liquor, and 5g / L of leveling agent and penetrating agent are added. The dipping box is a high temperature box, and the padding box is a room temperature box. One dipping box can be set The independent temperature control device controls the temperature individually. Usually the dyeing solution is prepared, and then the dyeing solution is diluted by 2 times, and then put into the dip dyeing box and the padding box respectively. Both the leveling agent and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com