High-airtightness passive house and construction process thereof

A construction technology and passive house technology, applied in the field of passive house, can solve the problems of insufficient utilization of exhausted gas, low resource utilization efficiency, and inability to allow fresh air to enter the room, and achieve strong air tightness, good thermal insulation effect, Safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

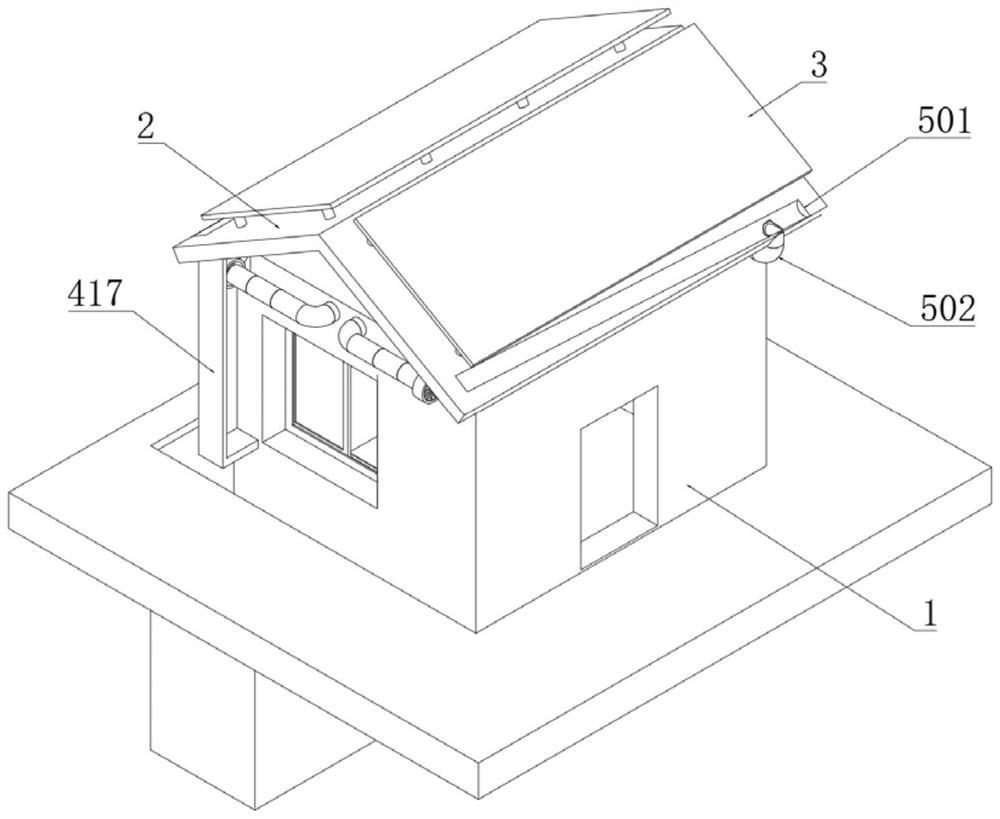

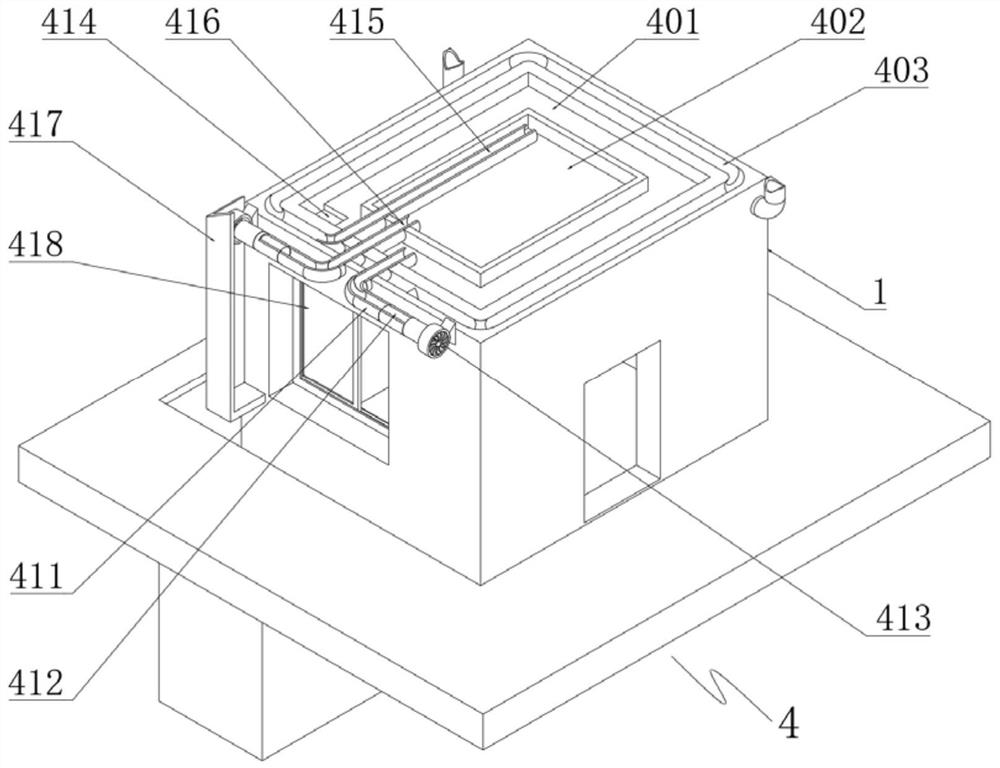

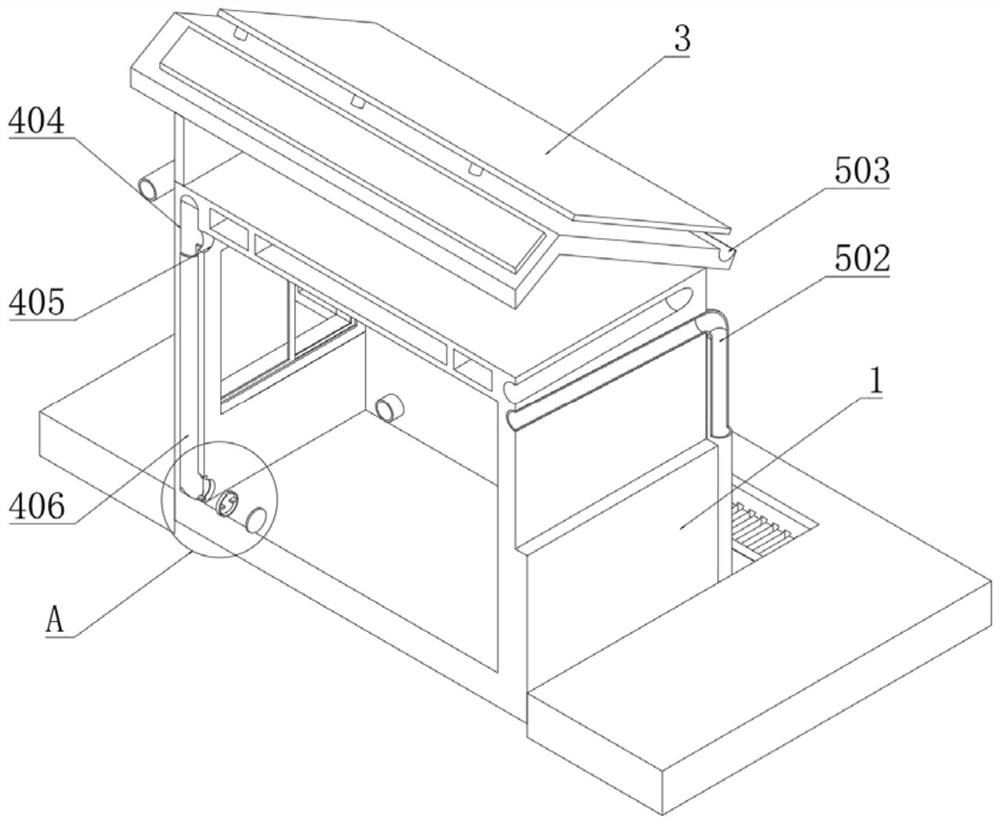

[0050] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a highly airtight passive house, comprising a wall 1, a roof 2 is installed on the top of the wall 1, a solar panel 3 is installed on the top of the roof 2, and the wall 1 Fresh air components are installed on the top;

[0051] The fresh air assembly 4 includes a ventilation chamber 401, an inner air chamber 402, an outer air chamber 403, an air conveying groove 404, an upper air hole 405, an arc baffle 406, a lower air hole 407, a lifting block 408, a rotating ring 409, and a sealing cover 410 , air inlet pipe 411, fresh air filter element 412, blower fan 413, air inlet hole 414, connecting air pipe 415, exhaust pipe 416, exhaust baffle 417 and window 418;

[0052] There is a ventilation chamber 401 in the middle of the top of the wall 1, and an inner air chamber 402 is opened on the top of the wall 1 corresponding to the inside of the ventilation chamber 401, and the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com