Fault monitoring method for reciprocating equipment

A fault monitoring, reciprocating technology, applied in the direction of mechanical equipment, pump testing, measuring devices, etc., can solve the problems of difficult to determine the corresponding relationship between frequency bands and faulty components, lack of effective training samples, low degree of automation, etc., and achieve significant monitoring sensitivity , to ensure accuracy, and to monitor the effects of increased sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

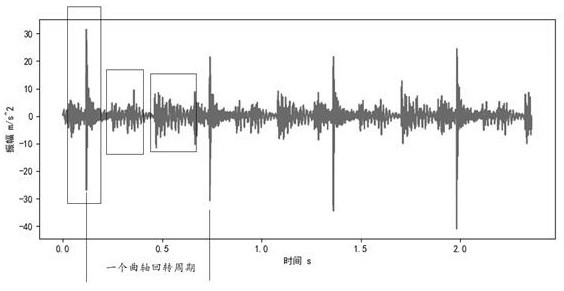

[0044] The invention discloses a fault monitoring method for reciprocating equipment, focusing on the vibration signal during the operation of the equipment, taking the reciprocating equipment as a three-cylinder mud pump as an example, which drives the drive through the crankcase (crankshaft connecting rod structure) The rotary motion of the machine part is converted into the reciprocating motion of the output system part. When the piston in the output system moves to the limit position every time, a vibration shock will be generated. Specifically, the vibration signal diagram of a cylinder head of a three-cylinder mud pump is as follows figure 1 shown.

[0045] From figure 1 It can be known that in one crankshaft revolution cycle of the crankcase part, when the piston in the cylinder closest to the sensor moves to the stop position, a vibration shock appears on the vibration signal; and when the other two distances are slightly When the pistons in the far cylinders also arri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com