Motor vehicle brake hub radiator

A technology for radiators and brake hubs, applied in the types of brakes, brake components, mechanical equipment, etc., can solve the problems of reduced heat dissipation, easy corrosion of metal materials, and brake failure, etc., to improve brittleness, reduce temperature, and guarantee The effect of the braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

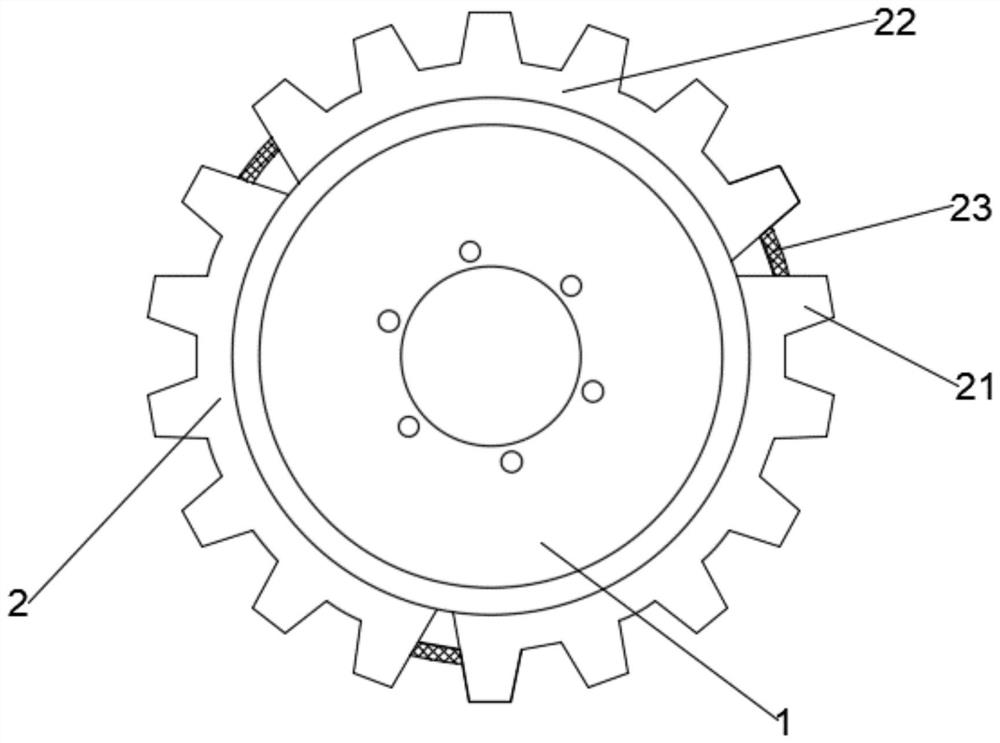

[0037] A motor vehicle brake hub radiator, such as figure 1 As shown, it includes a radiator body 2 for being sleeved on the brake hub 1. The outer surface of the radiator body 2 is provided with a heat dissipation arc 22, and the outer surface of the heat dissipation arc 22 is provided with several heat dissipation protrusions arranged at equal intervals. block 21;

[0038] The radiator body 2, the heat dissipation arcs 22 and the heat dissipation bumps 21 are all made of high heat dissipation aluminum alloy materials, and the outer surfaces of the radiator body 2, the heat dissipation arcs 22 and the heat dissipation bumps 21 are all coated with Covered with a high thermal conductivity anti-corrosion layer.

[0039] The heat dissipation bump 21 is a trapezoidal structure with a narrow outside and a wide inside.

[0040] The number of the heat dissipation arcs 22 is at least two, and the adjacent two heat dissipation arcs 22 are connected end to end by bolts 23, and the hea...

Embodiment 2

[0059] A motor vehicle brake hub radiator, such as figure 1 As shown, it includes a radiator body 2 for being sleeved on the brake hub 1. The outer surface of the radiator body 2 is provided with a heat dissipation arc 22, and the outer surface of the heat dissipation arc 22 is provided with several heat dissipation protrusions arranged at equal intervals. block 21;

[0060] The radiator body 2, the heat dissipation arcs 22 and the heat dissipation bumps 21 are all made of high heat dissipation aluminum alloy materials, and the outer surfaces of the radiator body 2, the heat dissipation arcs 22 and the heat dissipation bumps 21 are all coated with Covered with a high thermal conductivity anti-corrosion layer.

[0061] The heat dissipation bump 21 is a trapezoidal structure with a narrow outside and a wide inside.

[0062] The number of the heat dissipation arcs 22 is at least two, and the adjacent two heat dissipation arcs 22 are connected end to end by bolts 23, and the hea...

Embodiment 3

[0081] A motor vehicle brake hub radiator, such as figure 1 As shown, it includes a radiator body 2 for being sleeved on the brake hub 1. The outer surface of the radiator body 2 is provided with a heat dissipation arc 22, and the outer surface of the heat dissipation arc 22 is provided with several heat dissipation protrusions arranged at equal intervals. block 21;

[0082] The radiator body 2, the heat dissipation arcs 22 and the heat dissipation bumps 21 are all made of high heat dissipation aluminum alloy materials, and the outer surfaces of the radiator body 2, the heat dissipation arcs 22 and the heat dissipation bumps 21 are all coated with Covered with a high thermal conductivity anti-corrosion layer.

[0083] The heat dissipation bump 21 is a trapezoidal structure with a narrow outside and a wide inside.

[0084] The number of the heat dissipation arcs 22 is at least two, and the adjacent two heat dissipation arcs 22 are connected end to end by bolts 23, and the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com