Multistage phase change heat storage temperature stratification water tank

A phase-change heat storage and temperature stratification technology, applied in solar heat storage, fluid heaters, solar thermal energy, etc., can solve the problems of large heat loss, degradation of thermal energy quality, slow heat storage and heat extraction rate, etc. The effect of intermediate heat exchange, rapid energy storage and release, efficient storage and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and test of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific examples described here are only used to explain the present invention, not to limit the present invention.

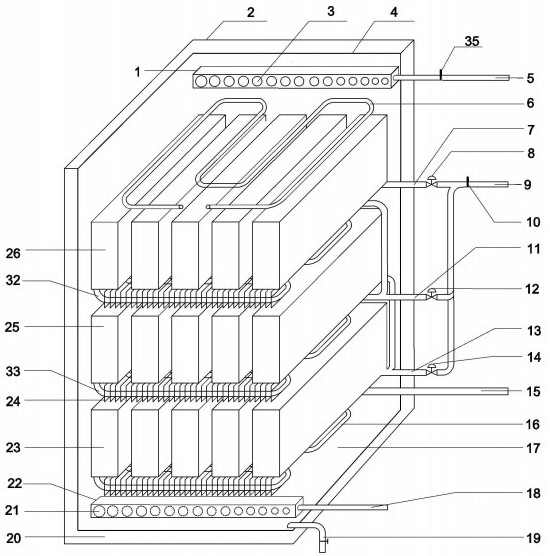

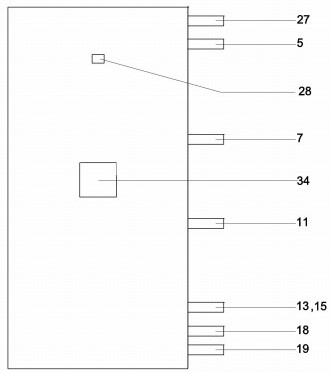

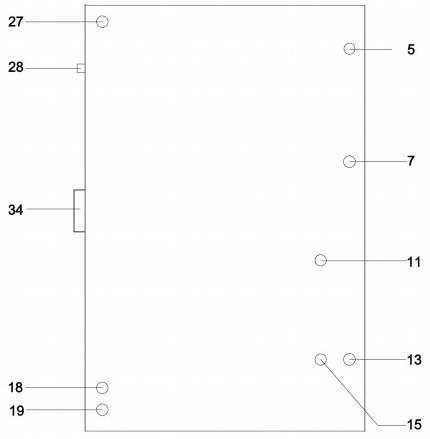

[0035]The invention proposes a multi-stage phase change heat storage temperature stratified water tank based on the deficiency of the heat exchange technology of the existing phase change heat storage tank. The phase change heat storage tank not only organically combines the advantages of fast sensible heat storage rate and high latent heat storage density, but also can realize energy storage and energy consumption according to quality, which can greatly improve the utilization efficiency of energy exergy and heat source side heat transfer efficiency. The cold and hot medium of the phase change hot water storage tank can be the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com