Medium-high strength titanium alloy cyclic loading test method

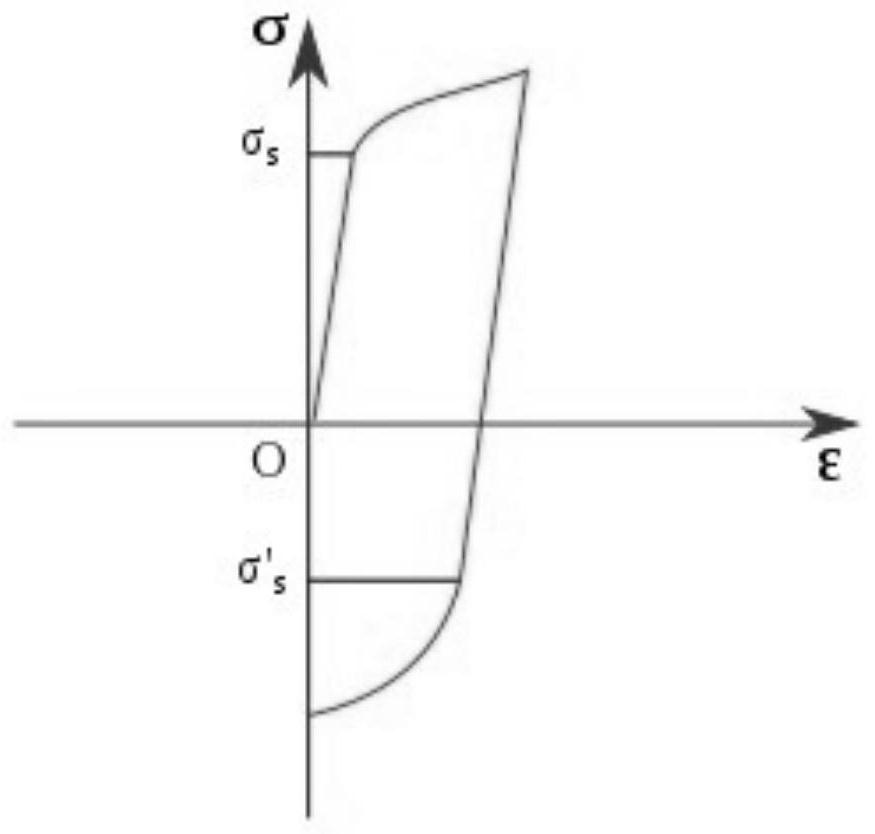

A cyclic loading and test method technology, applied in the direction of strength characteristics, using repetitive force/pulse force to test material strength, and using stable tension/pressure test to test material strength, etc., can solve the problem of unavailability of test data and compression instability. and other problems to achieve the effect of facilitating the Bauschinger effect and avoiding bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0026] Such as Figure 1-8 As shown, the medium and high strength titanium alloy cyclic loading test method of the present embodiment comprises the following steps:

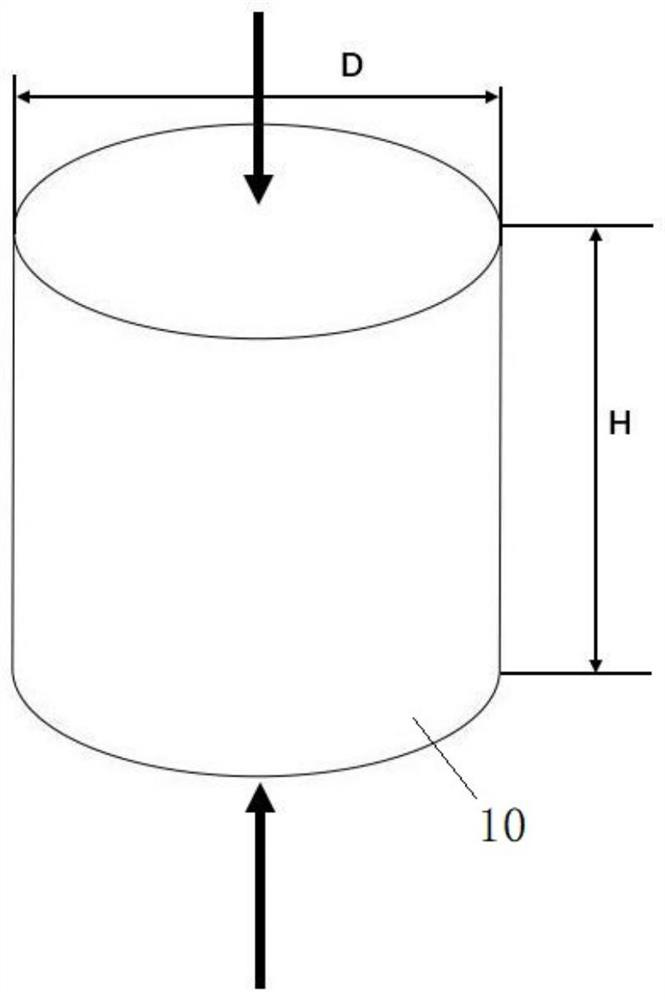

[0027] a. The initial sample 10 required for processing: determine the specifications of the initial sample 10 to be prepared according to the elongation of the medium-high strength titanium alloy and the expected number of cyclic loading;

[0028] b. Put the initial sample 10 on the material testing machine to carry out the compression loading test, and the supporting software on the material testing machine displays the load-displacement curve, which is converted into a stress-strain curve by the conversion formula;

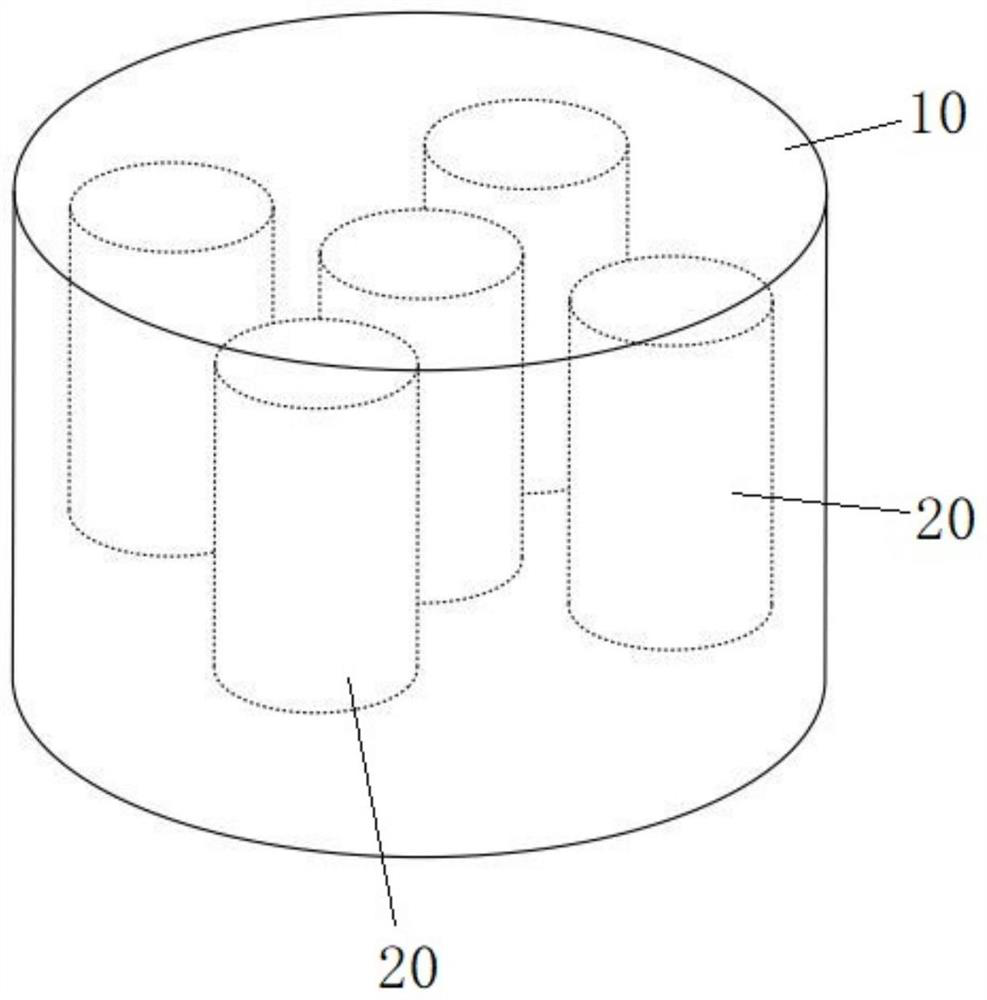

[0029] c. Carry out machining on the compressed initial sample 10 to obtain a tensile test piece 20;

[0030] d. Perform a tensile test on the obtained tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com