Subway buried metal pipeline corrosion optical fiber monitoring device and method

A technology for metal pipelines and monitoring devices, applied in the direction of material magnetic variables, etc., can solve the corrosion hazards of subway buried metal pipelines, reduce the service life and durability of buried metal pipelines, and electrochemical corrosion of the main steel structure of the subway system. To achieve the effect of low cost and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of this patent will be further described below in conjunction with the accompanying drawings.

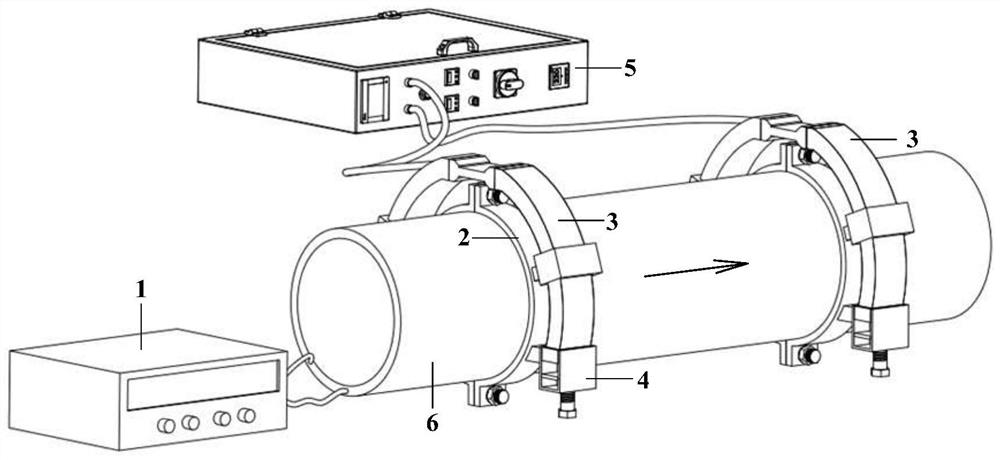

[0023] The present invention proposes an optical fiber monitoring device for corrosion of underground metal pipelines in subways, which includes an excitation unit (1), a support unit (2), a sensing unit (3), a pretension unit (4), and a control unit (5) );

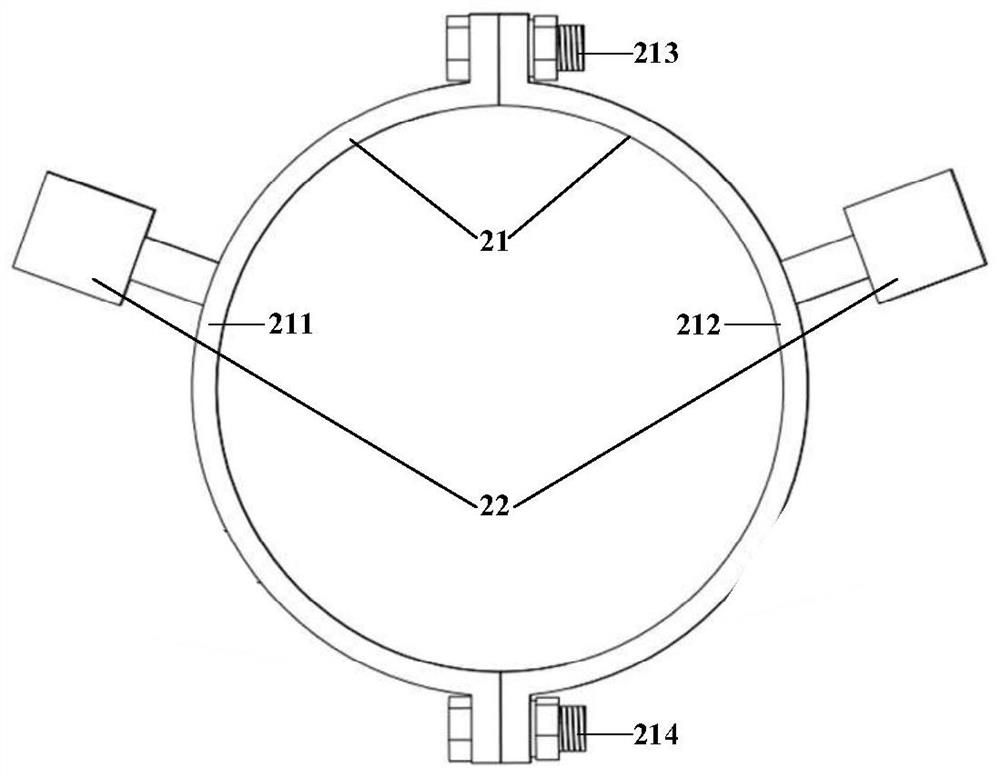

[0024] The support unit (2) includes a support fastener (21) and a magnet slot (22), and the support fastener (21) is two symmetrical first semicircle-shaped steel structures (211) and a second semicircle arc steel structure (212), the two ends of the first semicircle-arc steel structure (211) and the second semicircle-arc steel structure (212) are respectively connected by first bolts (213) and second bolts (214) to form steel Ring, two magnet guide slots (22) are symmetrically arranged on the outer sides of the semicircular arc steel structures (211) and (212);

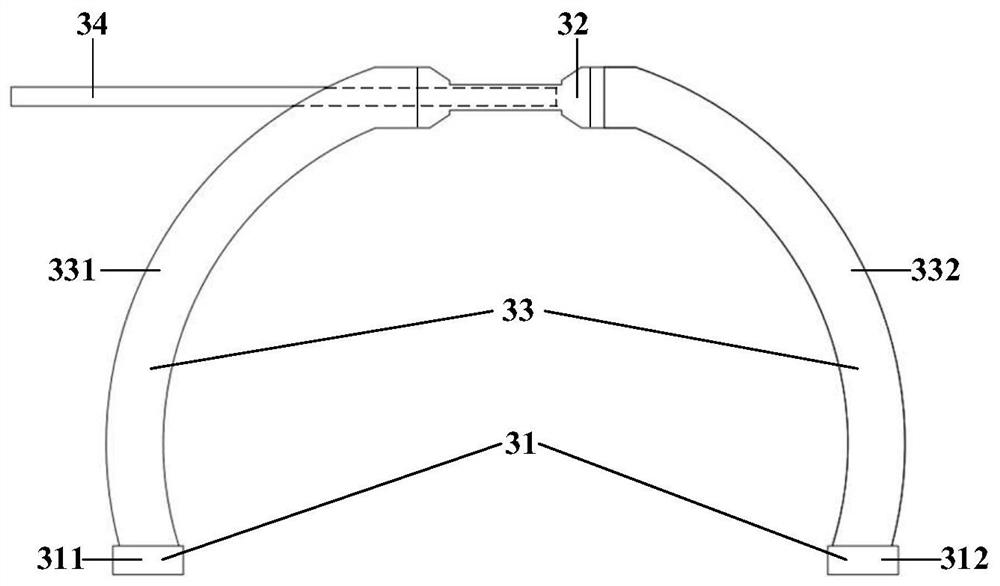

[0025] The sensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com