Turbofan engine design parameter optimization method

A turbofan engine and design parameter technology, which is applied in the optimization field of turbofan engine design parameters of direct binary exhaust system, can solve problems such as engine failure and thrust loss, and achieve simple optimization process and low fuel consumption efficiency, the effect of low infrared radiation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

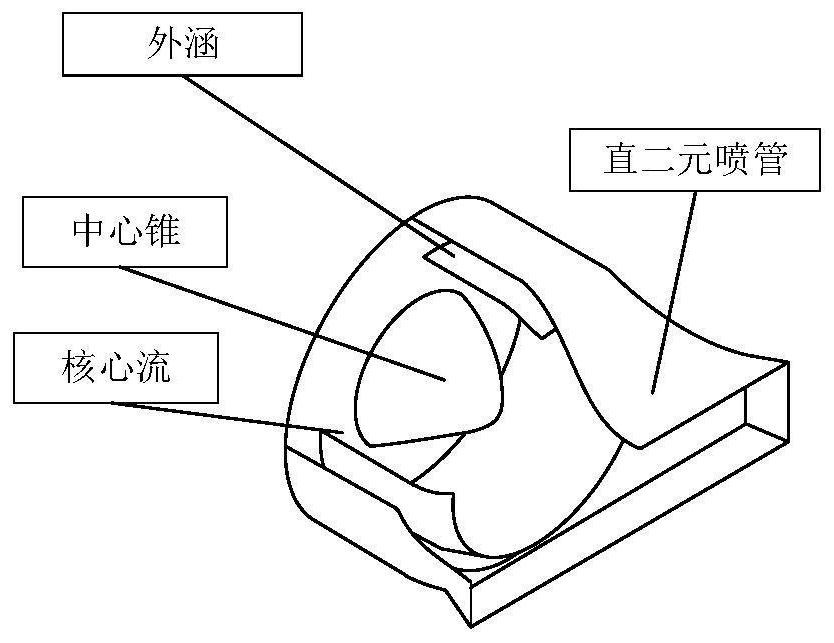

[0028] Compared with the traditional axisymmetric exhaust system, the straight binary exhaust system can effectively reduce the projected area of the internal high-temperature wall (such as the central cone wall, etc.) on the outlet of the exhaust system, thereby reducing the infrared radiation intensity of the exhaust system, directly The shape of the binary nozzle is as figure 1 shown.

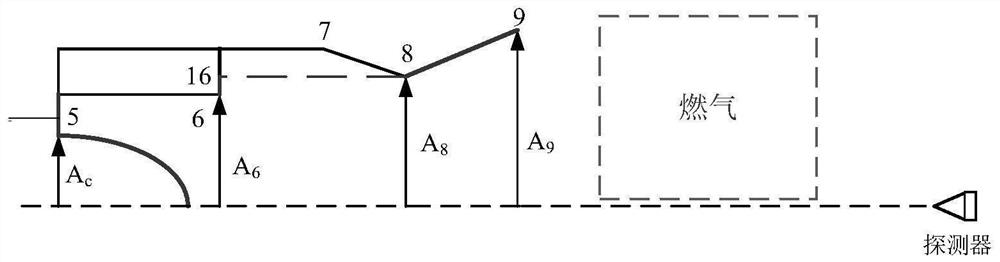

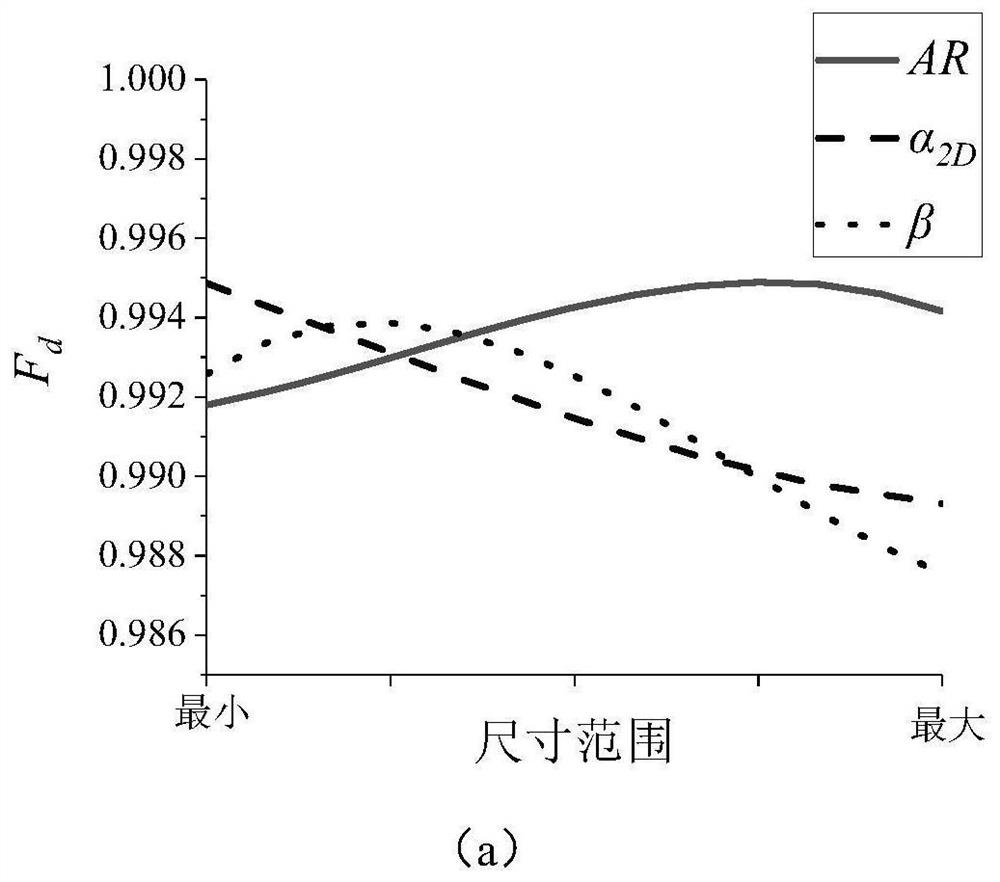

[0029] For the turbofan engine adopting straight binary exhaust system, the solution idea of the present invention is to aim at high thrust, low fuel consumption rate and low infrared radiation intensity, carry out multi-objective optimization to the design parameters, and optimize the design of the model to Reduce computational complexity. To achieve this goal, the technical scheme proposed by the present invention is specifically as follows:

[0030] A method...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap