Multilayer wiring adapter plate and preparation method thereof

A multi-layer wiring and adapter board technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as difficult preparation of multi-layer wiring adapter boards, achieve preparation and stress problems, and improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] refer to Figure 8 , this embodiment provides a multilayer wiring adapter board, the multilayer wiring adapter board includes:

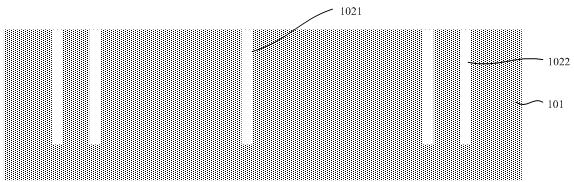

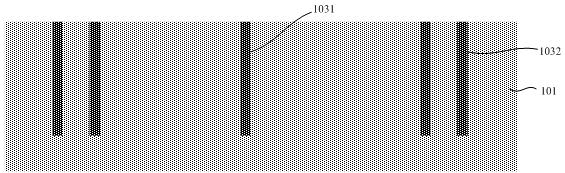

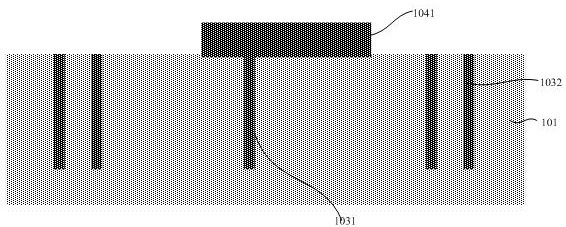

[0049] A substrate 101, wherein the substrate 101 has a first TSV column 1031 and a second TSV column 1032, and the first TSV column 1031 and the second TSV column 1032 both penetrate the substrate 101;

[0050] The first rewiring structure 104, the first rewiring structure 104 is located on the first surface of the substrate 101, including a first rewiring area A1 and a second rewiring area B1, in the first rewiring area A1 There is a first RDL metal wiring 1041, and there is a second RDL metal wiring 1042 in the second redistribution area B1, and the first RDL metal wiring 1041 is electrically connected to the first end of the first TSV column 1031, and the The second RDL metal wiring 1042 is electrically connected to the first end of the second TSV column 1032, and the thickness of the first RDL metal wiring 1041 is greater than the thickn...

Embodiment 2

[0082] refer to Figure 12 , this embodiment also provides a multilayer wiring adapter board, the difference between the multilayer wiring adapter board and the multilayer wiring adapter board in Embodiment 1 is that the first RDL metal is formed in this embodiment The step of wiring follows the step of forming two RDL metal wirings.

[0083] Specifically, the multilayer wiring adapter board includes:

[0084] a base 201, wherein the base 201 has a first TSV column 2031 and a second TSV column 2032, and the first TSV column 2031 and the second TSV column 2032 both penetrate the base 201;

[0085] The first rewiring structure 204, the first rewiring structure 204 is located on the first surface of the substrate 201, including a first rewiring area A2 and a second rewiring area B2, in the first rewiring area A2 There is a first RDL metal wiring 2041, and there is a second RDL metal wiring 2042 in the second redistribution area B2, and the first RDL metal wiring 2041 is electri...

Embodiment 3

[0091] refer to Figure 16 , this embodiment also provides a multilayer wiring adapter board, the difference between the multilayer wiring adapter board and the multilayer wiring adapter board in Embodiment 1 is that the first RDL metal is formed in this embodiment The step of wiring follows the step of forming two RDL metal wirings.

[0092] Specifically, the multilayer wiring adapter board includes:

[0093] a base 301, wherein the base 301 has a first TSV column 3031 and a second TSV column 3032, and the first TSV column 3031 and the second TSV column 3032 both penetrate the base 301;

[0094] The first rewiring structure 304, the first rewiring structure 304 is located on the first surface of the substrate 301, including a first rewiring area A3 and a second rewiring area B3, in the first rewiring area A3 There is a first RDL metal wiring 3041, and there is a second RDL metal wiring 3042 in the second redistribution area B3, and the first RDL metal wiring 3041 is electri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com