Method for removing cyanide in gold smelting red slag through washing method

A cyanide and gold technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems affecting comprehensive utilization, etc., and achieve the effects of convenient operation, strong environmental protection, and remarkable decyanation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

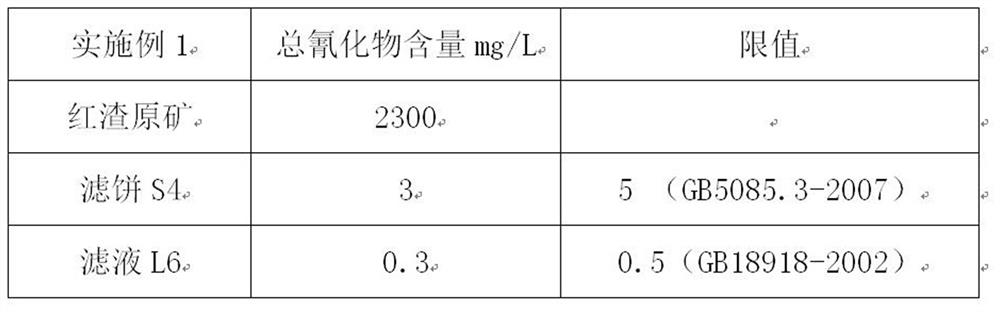

[0037] The gold smelting red slag selected in this embodiment is taken from Lingbao Gold Investment Co., Ltd. The gold smelting red slag sample was tested for the cyanide content of the toxic immersion liquid before treatment, and the measurement results showed that the total cyanide content was 2300mg / L . The specific processing process is:

[0038] Take 2500g of gold smelting red slag, and make pulp with clear water to obtain pulp P1 with a solid content of 30%; press filter the pulp P1 to obtain filter cake S1 and filtrate L1 with a moisture content of 12%; filter cake S1 with clear water to prepare into pulp P2 with a solid content of 30%; press filter the pulp P2 to obtain filter cake S2 and filtrate L2 with a moisture content of 12%; filter cake S2 is made into pulp P3 with a solid content of 30% with clear water; Press filtration to obtain filter cake S3 and filtrate L3 with a moisture content of 12%; use clean water to make filter cake S3 into pulp P4 with a solid...

Embodiment 2

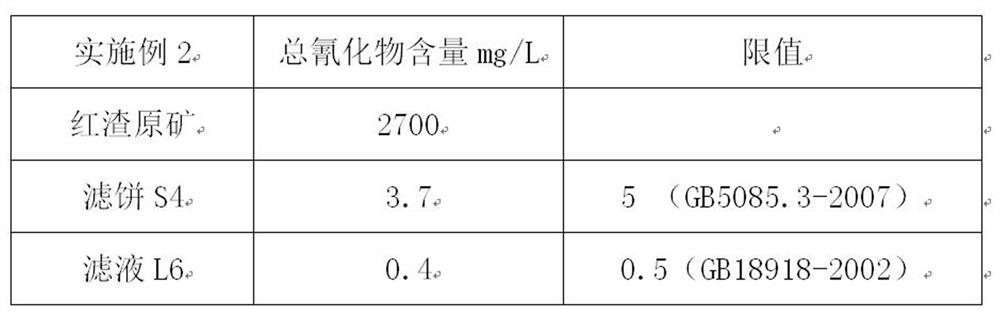

[0040] The gold smelting red slag selected in this embodiment is taken from Chenguang Smelter in Lingbao City. The gold smelting red slag sample was tested for the cyanide content of the toxic immersion liquid before treatment. The measurement results showed that the total cyanide content was 2700 mg / L. The specific processing process is:

[0041]Take 2500g of gold smelting red slag, and make pulp with clear water to obtain pulp P1 with a solid content of 40%; press filter the pulp P1 to obtain filter cake S1 and filtrate L1 with a water content of 10%; filter cake S1 with clear water to prepare into pulp P2 with a solid content of 40%; press filter the pulp P2 to obtain filter cake S2 and filtrate L2 with a moisture content of 10%; filter cake S2 is made into pulp P3 with a solid content of 40% with clear water; Press filtration to obtain filter cake S3 and filtrate L3 with a moisture content of 10%; use clean water to make filter cake S3 into pulp P4 with a solid content...

Embodiment 3

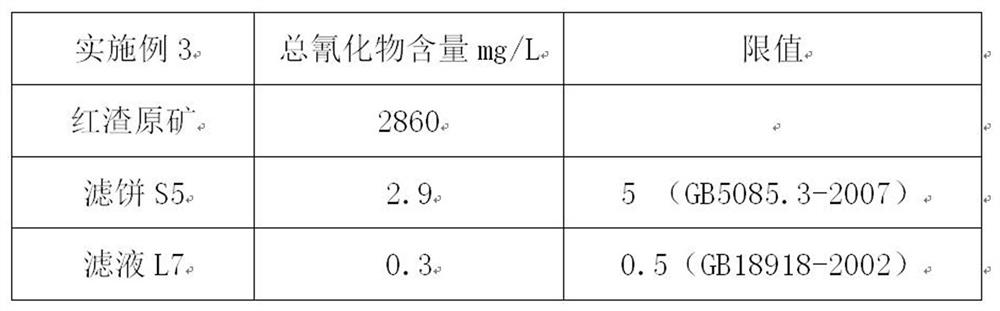

[0043] The gold smelting red slag selected in this embodiment is taken from the gold tailings in Yuling Town, Lingbao City. The gold smelting red slag sample was tested for the cyanide content of the toxic leaching liquid before treatment. The measurement results showed that the total cyanide content was 2860mg / L. The specific processing process is:

[0044] Take 2500g of gold smelting red slag, and make pulp with clear water to obtain pulp P1 with a solid content of 50%; press filter the pulp P1 to obtain filter cake S1 and filtrate L1 with a moisture content of 15%; filter cake S1 with clear water to prepare into pulp P2 with a solid content of 50%; press filter the pulp P2 to obtain filter cake S2 and filtrate L2 with a water content of 15%; filter cake S2 is made into pulp P3 with a solid content of 50% with clear water; Press filtration to obtain filter cake S3 and filtrate L3 with a moisture content of 15%; use clean water to make filter cake S3 into pulp P4 with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com