Quantum dot composite material, preparation method thereof and quantum dot light-emitting diode

A composite material and quantum dot technology, which is applied in the field of quantum dot composite materials and its preparation, and quantum dot light-emitting diodes, can solve the problems of low luminous efficiency of quantum dots, achieve the effects of improving luminous efficiency, easy regulation, and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

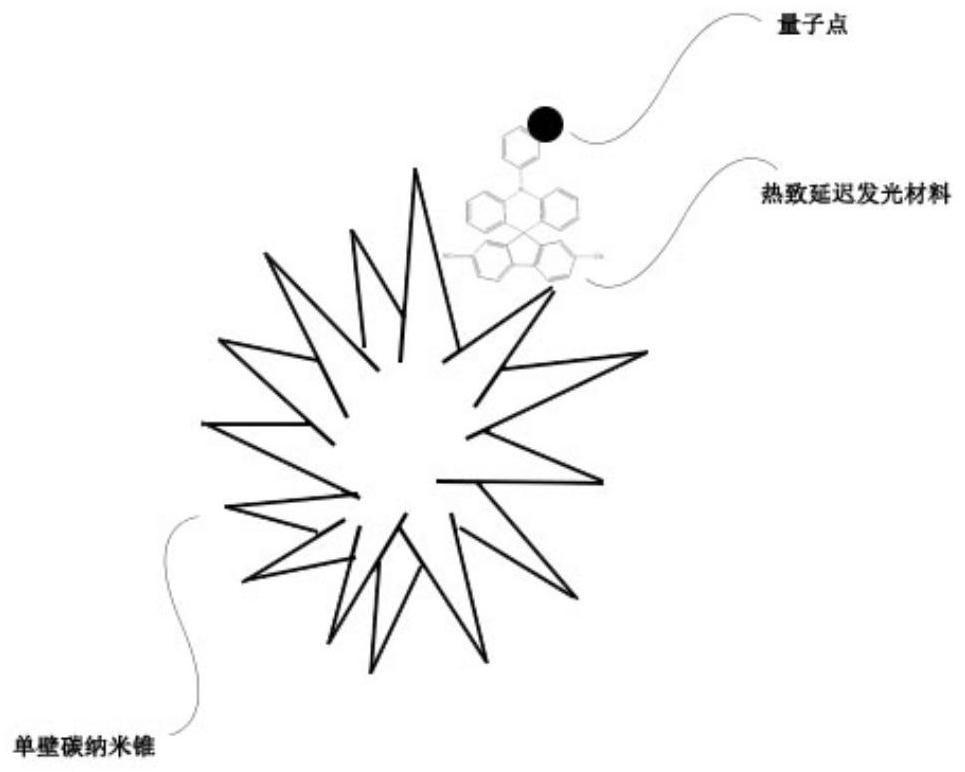

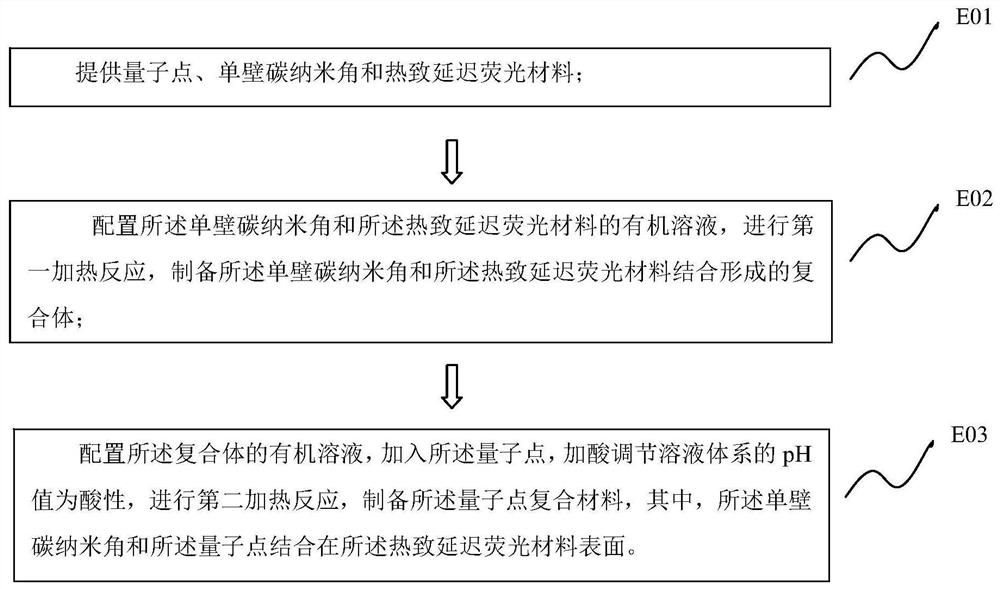

[0047] combine figure 2 , the second aspect of the embodiment of the present invention provides a method for preparing a quantum dot composite material, comprising the following steps:

[0048] S01. Provide quantum dots, single-walled carbon nanohorns and thermally induced delayed fluorescence materials;

[0049] S02. configuring the organic solution of the single-walled carbon nanohorn and the thermally induced delayed fluorescent material, performing a first heating reaction, and preparing a complex formed by combining the single-walled carbon nanohorn and the thermally induced delayed fluorescent material;

[0050] S03. Configure the organic solution of the complex, add the quantum dots, add acid to adjust the pH value of the solution system to be acidic, perform a second heating reaction, and prepare the quantum dot composite material, wherein the single-walled carbon nano Corners and the quantum dots are combined on the surface of the thermally delayed fluorescent mater...

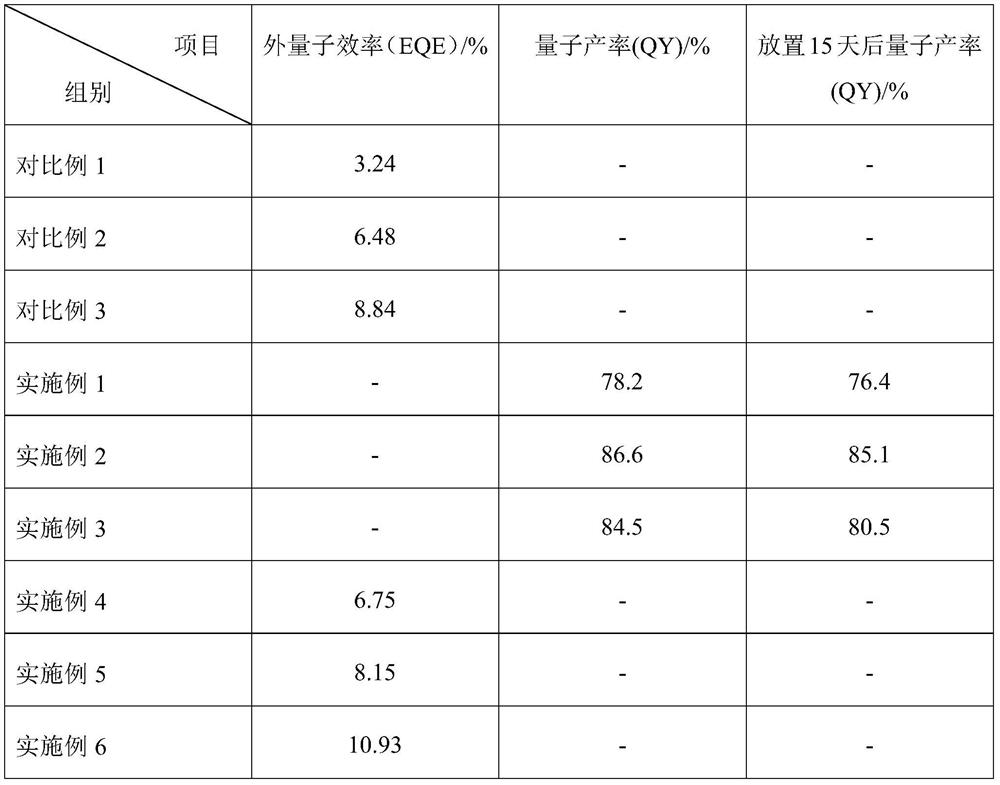

Embodiment 1

[0111] A kind of quantum dot composite material, its preparation method comprises the following steps:

[0112] Take 4 mg of single-walled carbon nanohorns and ultrasonically disperse them in 25 mL of deionized water, add 15 mL of concentrated sulfuric acid, heat and reflux at 120 ° C for 4 h, let stand at room temperature, remove the supernatant, wash and centrifuge, and then vacuum dry at 70 ° C for 12 h; Take 1.5 mg of solid and redisperse it into 10 mL of deionized water to form a suspension, add 0.2 mmol of dicyclohexylcarbodiimide, stir at room temperature for 6 min, then add 6 mmol of mercaptoethylamine, continue stirring for 3 h, and obtain thiol-modified single-wall Carbon nanohorns, dispersed in ethanol, the concentration is 3mg / mL;

[0113] 2mmol TPA-QNX(CN) 2 Disperse in 10ml of ethanol and water mixed solvent (ratio 3:1), add sulfuric acid to adjust the pH value to 3, reflux and heat to 75°C, and react for 1.5h to make TPA-QNX(CN) 2 The cyano group is hydrolyzed...

Embodiment 2

[0117] A kind of quantum dot composite material, its preparation method comprises the following steps:

[0118] Take 4 mg of single-walled carbon nanohorns and ultrasonically disperse them in 30 mL of deionized water, add 15 mL of concentrated sulfuric acid, heat and reflux at 120 ° C for 5 h, let stand at room temperature, remove the supernatant, wash and centrifuge, and then vacuum dry at 70 ° C for 12 h; Take 2 mg of solid and redisperse it into 10 mL of deionized water to form a suspension, add 0.3 mmol of diisopropylcarbodiimide (DIC), stir at room temperature for 10 min, then add 8 mmol of 2-(butylamino)ethanethiol, and continue stirring 4h, after washing, sulfhydryl-modified single-walled carbon nanohorns were obtained, which were dispersed in ethanol at a concentration of 6 mg / mL;

[0119] Disperse 3mmol BFCz-2CN in 10ml of ethanol and water mixed solvent (ratio 3:1), add sulfuric acid to adjust the pH value to 2, reflux and heat to 80°C, and react for 1h to hydrolyze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com