Steel-concrete reinforced plastic water supply pipe, water supply pipe system and construction method of water supply pipe

A technology of reinforced plastics and water supply pipes, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., and can solve the problems that the compressive capacity is not as good as that of steel wire concrete water supply pipes, the surface of concrete is rough, and the frictional resistance of water in pipes is large. Achieve the effect of high ring rigidity, low cost and small frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

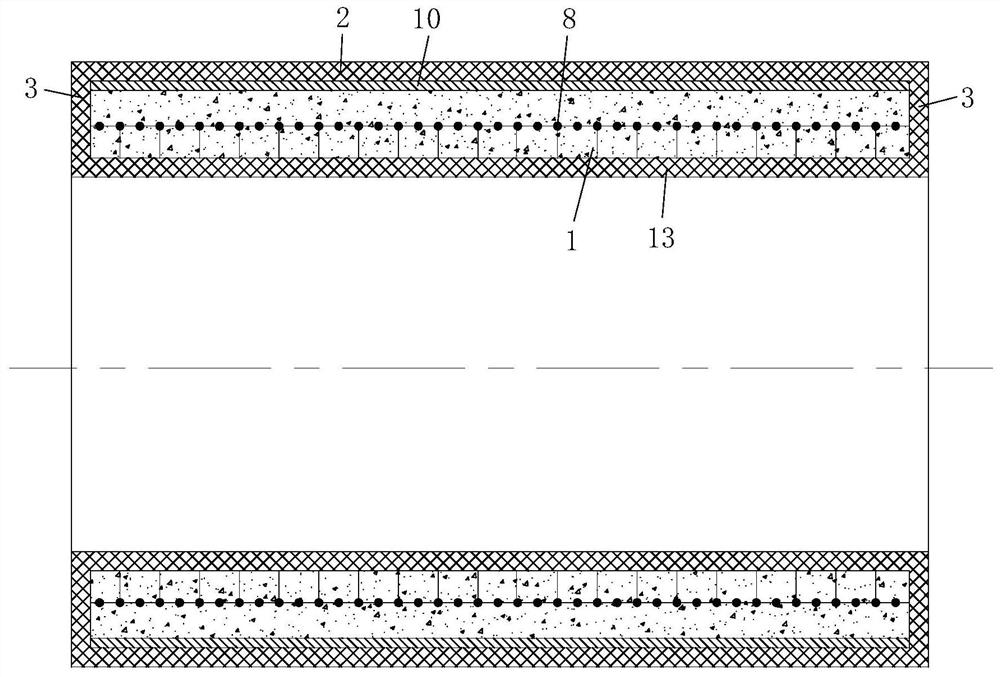

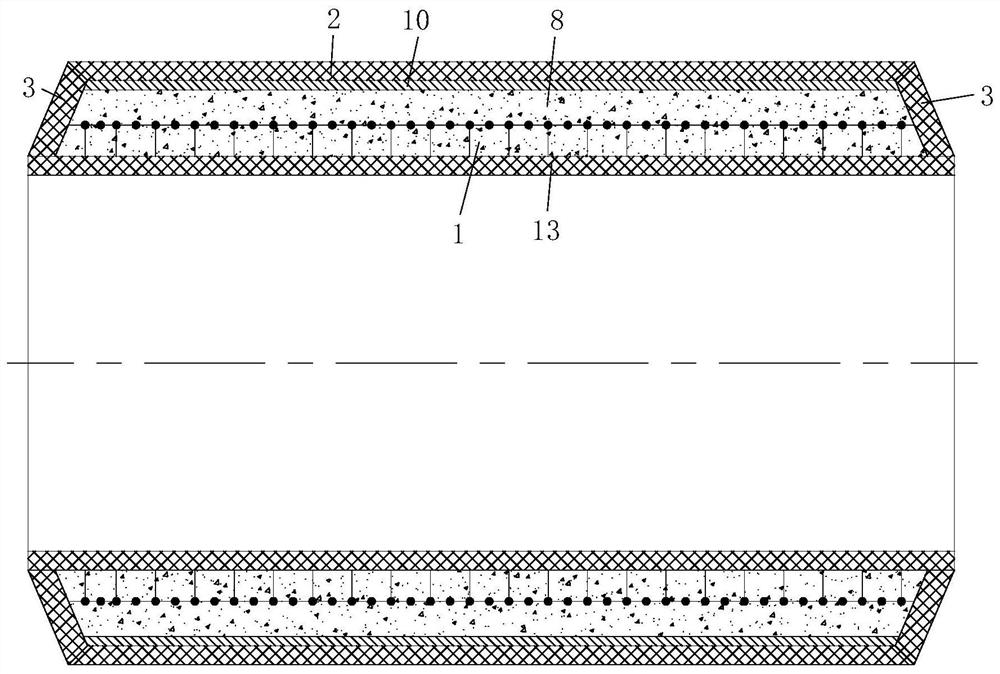

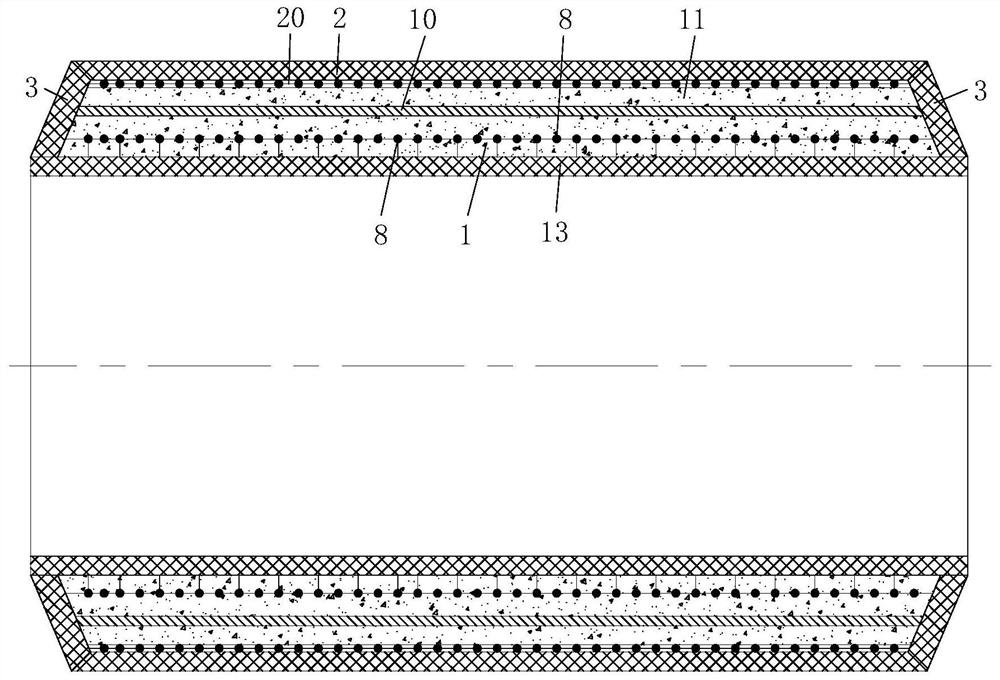

[0063] like Figure 1-4 As shown, the steel-concrete reinforced plastic water supply pipe described in this embodiment includes a concrete water pipe body 1, and the outer wall of the concrete water pipe body 1 is covered with a steel cylinder 10, and the two sides of the steel cylinder 10 are open. The outer wall of the steel cylinder 10 is covered with a first plastic plate 2, the inner wall of the concrete water pipe body 1 is covered with a second plastic plate 13, and the two ends of the concrete water pipe body 1 are covered with at least one third plastic plate 3, The third plastic plate 3 is sealingly connected with the first plastic plate 2 and the second plastic plate 13 respectively.

[0064] In the above scheme, the concrete water pipe body 1 is provided with a prestressed steel wire 3 8 to enhance the strength of the concrete water pipe body 1, and at the same time, the prestressed steel wire 3 8 is connected with the second plastic plate 13 to utilize The prestr...

Embodiment 2

[0077] like Figure 5 and 6 As shown in the prior art, the ports of adjacent water supply pipes in the prior art are usually connected by flanges, and since the contact ports of adjacent water supply pipes cannot be as flat as the side walls at the interface, adjacent When the water supply pipe is connected by a flange, the flange is not easy to compress the seal. This embodiment provides a steel-concrete reinforced plastic water supply pipe system, including a compression device 9 and at least two The steel-concrete reinforced plastic water supply pipe 5 is sealed with a sealing assembly 7 adjacent to the steel-concrete reinforced plastic water supply pipe 5, and the sealing assembly 7 is arranged at least one circle along the circumference of the steel-concrete reinforced plastic water supply pipe 5, The pressing device 9 is sleeved on the outside of the sealing assembly 7 and can compress the sealing assembly 7 from the outside of the sealing assembly 7 .

[0078] Specifi...

Embodiment 3

[0084] like Figure 7 and 8 As shown, this embodiment provides a steel-concrete reinforced plastic water supply pipe system, which is different from Embodiment 2 in that no sealing grooves are provided between adjacent steel-concrete reinforced plastic water supply pipes 5, but directly between adjacent steel-concrete reinforced plastic water supply pipes 5. A sealing assembly 7 is sleeved on the outer wall of the steel-concrete reinforced plastic water supply pipe 5 adjacent to the joint of the steel-concrete reinforced plastic water supply pipe 5. Specifically, the sealing assembly 7 is sleeved on the outer side of the steel-concrete reinforced plastic water supply pipe 5, two adjacent The steel-concrete reinforced plastic water supply pipe 5 and the corresponding sealing assembly 7 are sealed and fitted. The pressing device 9 is preferably a clamp, and the sealing assembly 7 is tightened by the clamp to reach the adjacent steel-concrete seal. The purpose of direct sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com