Vibration fluidized bed

A vibrating fluidized bed and bed body technology, which is applied to hearth furnaces, dry solid materials, furnaces, etc., can solve the problems of uneven material distribution, large bed burden, material deviation, etc., and achieve uniform material distribution and good coverage Wide, uniform vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

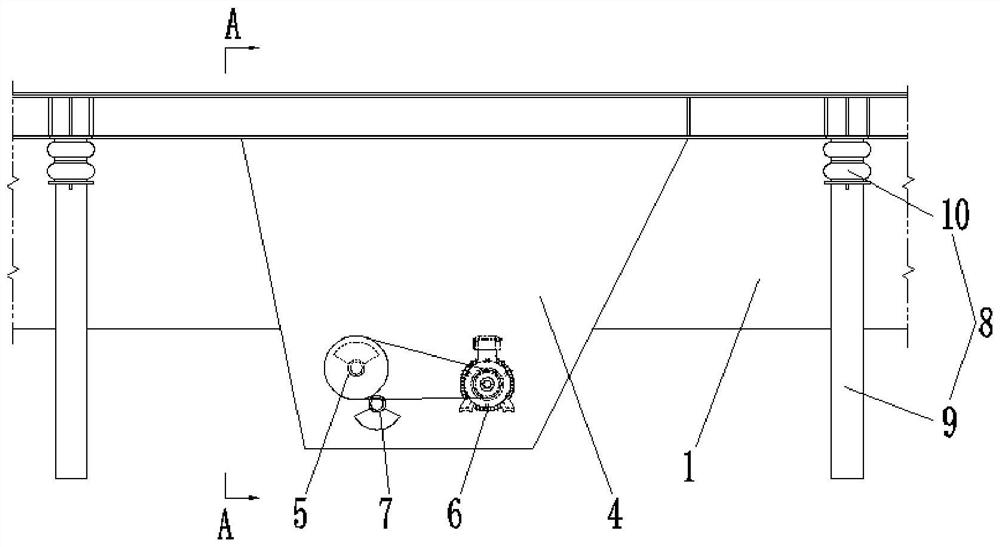

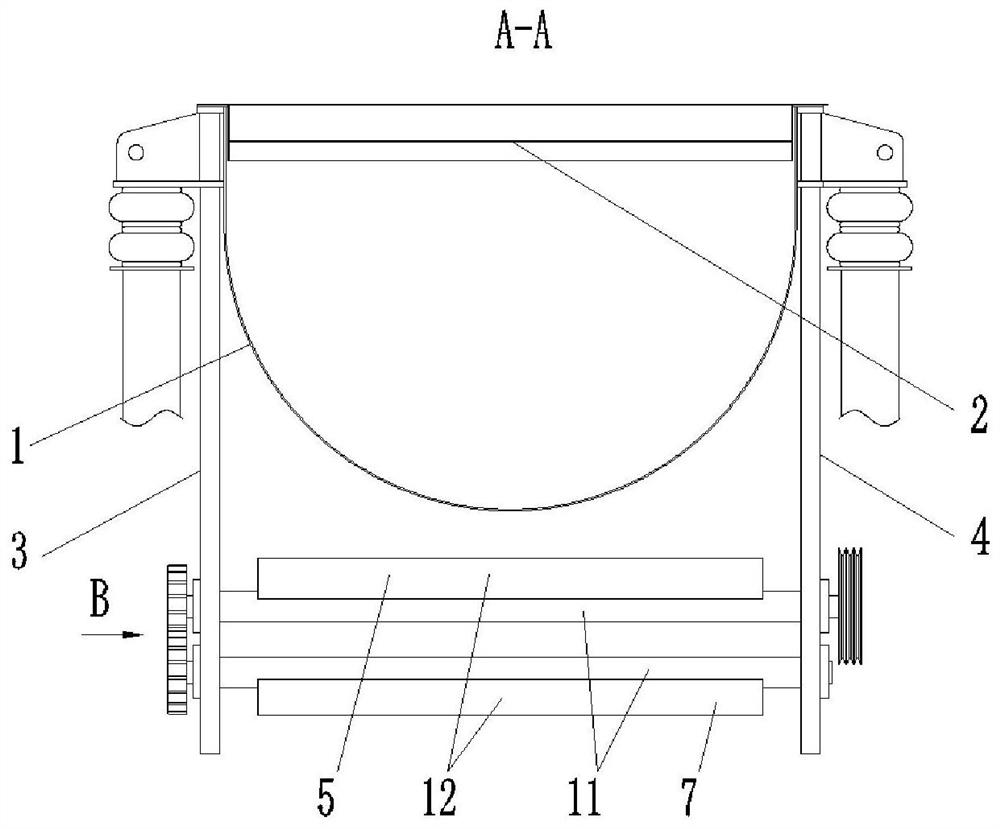

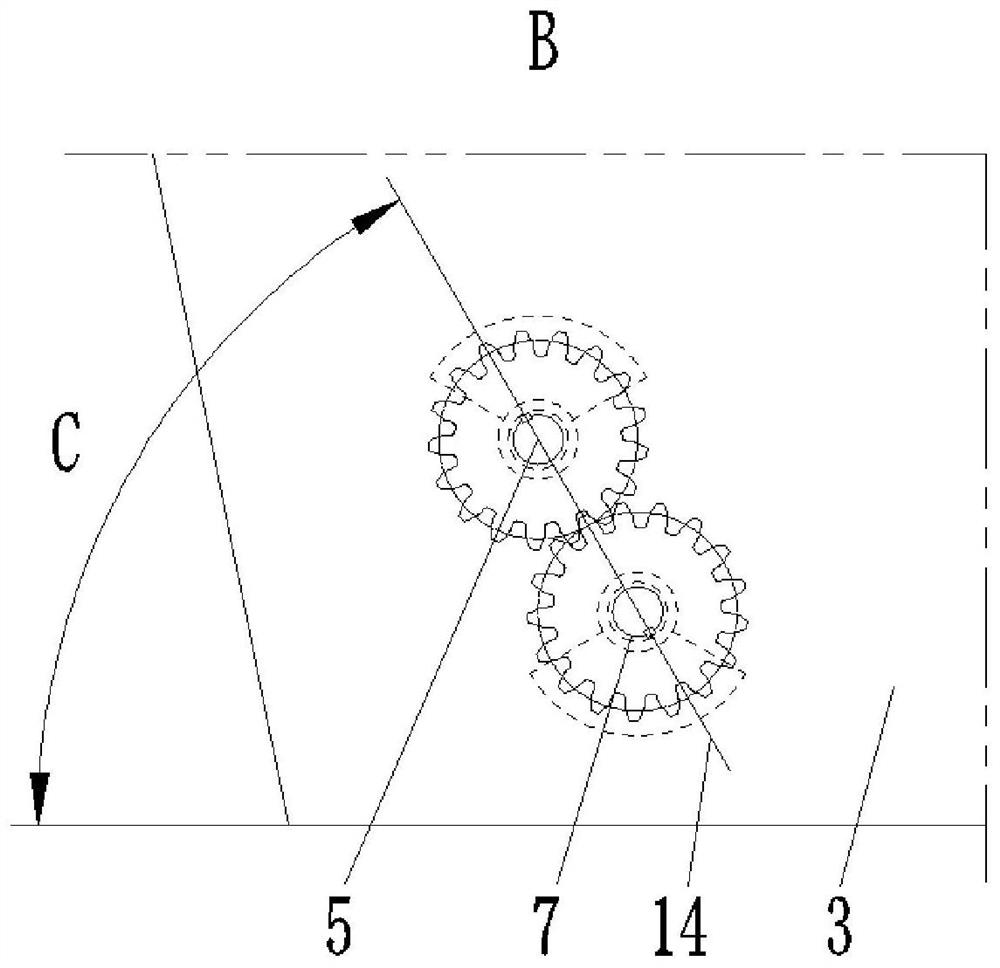

[0028] Such as Figure 1-6 , a vibrating fluidized bed, comprising a bed body 1 and an excitation device, the bed body 1 is provided with a punching material board 2 for carrying materials, and the vibration excitation device includes a front , the front and rear side plates 3,4 on the rear side, the upper and lower eccentric shafts 5,7 positioned directly below the bed body 1 are rotated between the front and rear side plates 3,4, and the upper eccentric shaft 5 Located above the lower eccentric shaft 7, the rear side plate 4 is provided with a motor 6 that cooperates with the rear end of the upper eccentric shaft 5, and the front end of the upper eccentric shaft 5 is coordinated with the lower eccentric shaft 7 through gear transmission , the transmission ratio of the gear transmission is 1.

[0029] The front and rear sides of the bed body 1 are provided with a plurality of air bag supports 8, the air bag supports 8 include a column 9, the top surface of the column 9 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com