Liquid cooling impact arch-shaped magnetic flux adjusting device

An adjustment device and flux modulation technology, applied in cooling/ventilation devices, electromechanical devices, magnetic circuits, etc., can solve the problems of affecting the service life of high-speed motors, adverse effects of high-speed motor operation, and low utilization of back-wound windings. Achieve the effects of increasing fault-tolerant operation capability, improving fault-tolerant operation capability, improving the scope of application and application ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

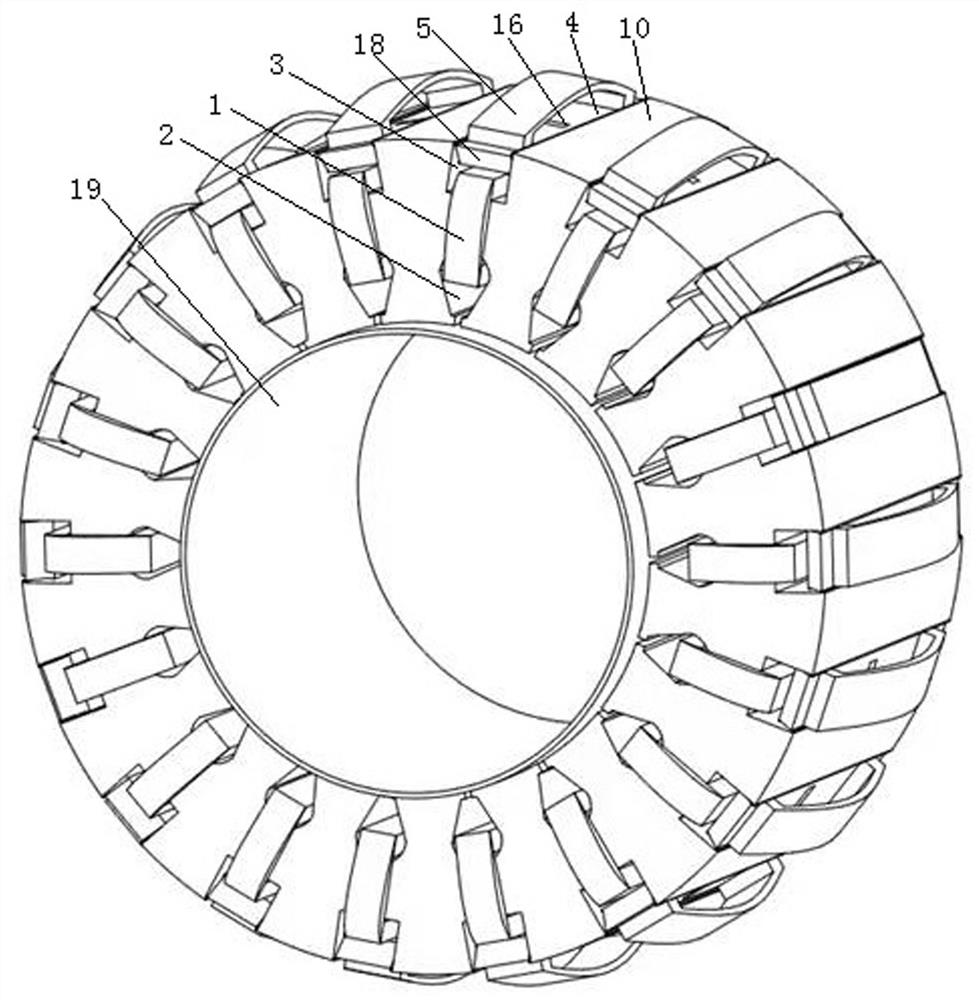

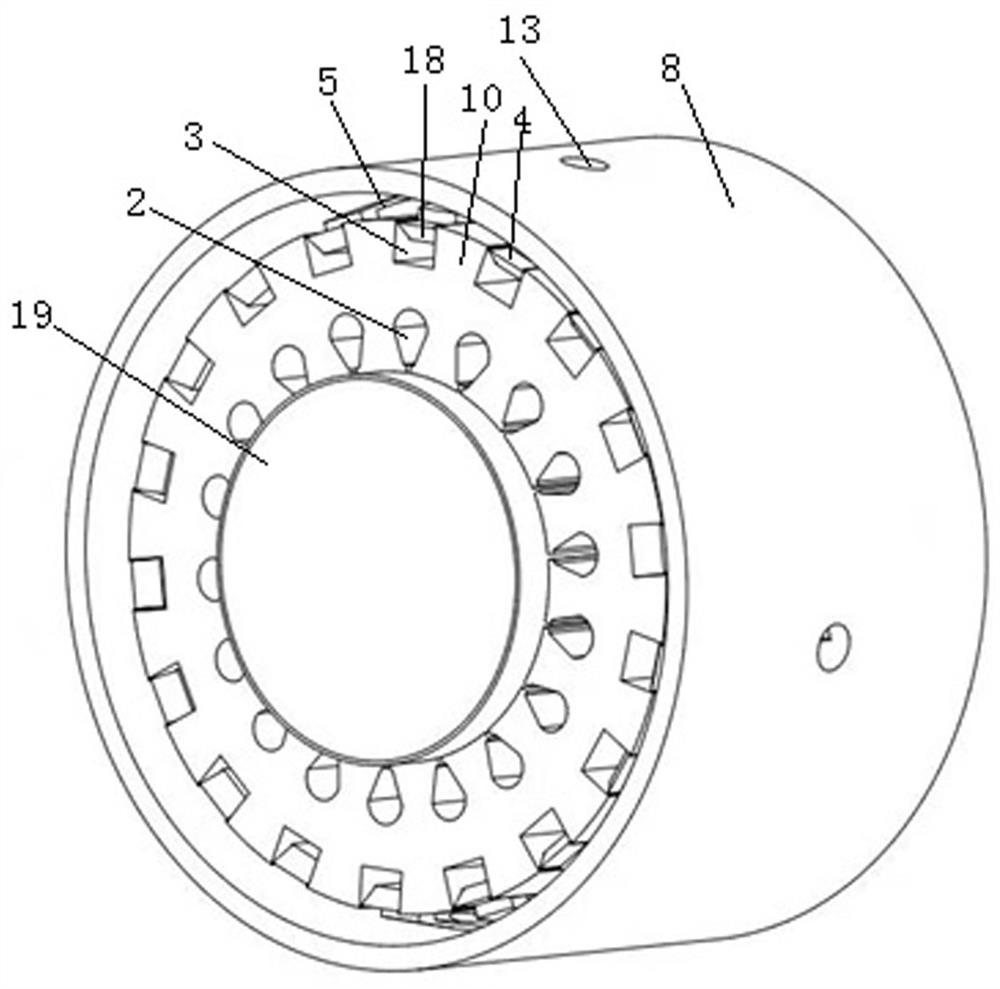

[0054] Embodiment 1: A liquid-cooled impact arch magnetic flux adjustment device, including a magnetic adjustment mechanism, the magnetic adjustment mechanism is arranged on a slotted stator, and the slotted stator is provided with mutually symmetrical inner stators with back-wound windings 1 Slot 2 and stator back slot 3, the magnetic modulation mechanism includes a magnetic flux modulation block 4 and an arched shrapnel 5 made of magnetically permeable materials;

[0055] Each stator back slot 3 slot on the slotted stator is respectively provided with a magnetic flux modulation block 4, the magnetic flux modulation block 4 and the two side walls of the stator back slot 3 are in a sliding and sealed connection, and the magnetic flux modulation block 4 Both sides of an end surface corresponding to the bottom of the stator back slot 3 are provided with first buckles 6 protruding toward the two side walls of the stator back slot 3, and the two ends of the opening of the stator ba...

Embodiment 2

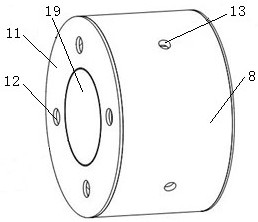

[0069] Embodiment 2: The difference from Embodiment 1 is that a first partition 21 is provided on the front end face and the rear end face of the slotted stator, and the first partition 21 is arranged corresponding to the connecting column 9 and is fixedly connected to the together, and one end of the first partition 21 close to the casing 8 is fixedly connected to the inner wall of the casing 8, and a second partition 22 is provided on the side of the casing end cover 11 close to the front end face and rear end face of the slotted stator, The first partition 21 and the second partition 22 are arranged correspondingly. After the casing end cover 11 and the casing 8 are connected together, the corresponding first partition 21 and the second partition 22 are connected in contact, and the first There is no gap between the partition 21 and the second partition 22, and the first partition 21 and the second partition 22 jointly divide the space between the casing 8 and the oil separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com