Coarse cereal pineapple bread

A technology of miscellaneous grains and pineapple, which is applied in the direction of pre-baked dough processing, legume baked food, baking, etc., to achieve the effect of improving taste and increasing attractiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

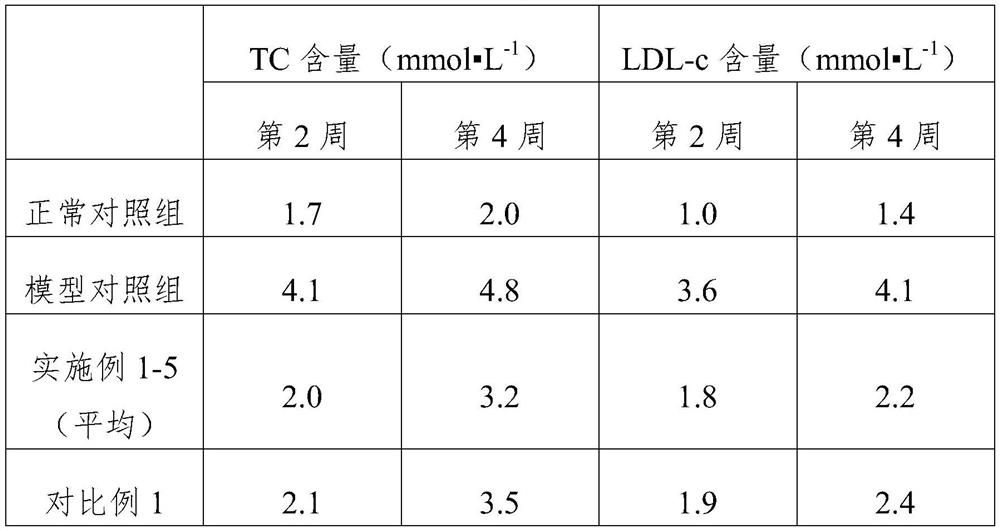

Examples

Embodiment 1

[0035] A multigrain pineapple bun consists of the following raw materials in parts by weight:

[0036] The raw materials of the dough are: 300 small miscellaneous grains, 300 high flour, 350 water, 150 soybean oligosaccharides, 40 maltodextrin, 80 eggs, 100 grapefruit powder, 80 cream, 30 milk powder, 8 yeast, 8 salt, and whey protein Powder 3;

[0037] The raw material composition of pineapple peel is: low flour 200, soybean lecithin 0.3, glyceryl monostearate 1, butter 100, whipped cream 30, custard powder 15, eggs 40, white sugar 120, toning powder 5, baking powder 5 .

[0038] The small miscellaneous grains are red beans, oats and sorghum.

[0039] The small miscellaneous grains need to be processed as follows: steam until half-cooked, ultrasonically treated for 10 minutes, dried, and crushed; the ultrasonic power is 120W;

[0040] The pulverization is carried out in a pulverizer, the power of the pulverizer is 150W, 1000r / min, and the time is 10min.

[0041] The pomel...

Embodiment 2

[0056] A multigrain pineapple bun consists of the following raw materials in parts by weight:

[0057]The raw materials of the dough are: 450 small miscellaneous grains, 500 high flour, 450 water, 200 soybean oligosaccharides, 50 maltodextrin, 120 eggs, 150 grapefruit powder, 90 cream, 50 milk powder, 12 yeast, 12 salt, whey protein Powder 6;

[0058] The raw material composition of pineapple peel is: low flour 300, soybean lecithin 0.6, glyceryl monostearate 1.5, butter 130, light cream 50, custard powder 30, egg 60, white sugar 160, toning powder 10, baking powder 10 .

[0059] The small miscellaneous grains are mung beans and sorghum.

[0060] The small miscellaneous grains need to be processed as follows: steam until half-cooked, ultrasonically treated for 20 minutes, dried, and crushed; the ultrasonic power is 150W;

[0061] The pulverization is carried out in a pulverizer, the power of the pulverizer is 180W, 1150r / min, and the time is 15min.

[0062] The pomelo powd...

Embodiment 3

[0077] A multigrain pineapple bun consists of the following raw materials in parts by weight:

[0078] The raw material composition of the dough is: small miscellaneous grains 350, high flour 350, water 4004, soybean oligosaccharides 160, maltodextrin 42, eggs 89, grapefruit powder 110, cream 82, milk powder 32, yeast 9, salt 9, whey protein Powder 4;

[0079] The raw material composition of pineapple peel is: low flour 240, soybean lecithin 0.4, glyceryl monostearate 1.2, butter 110, light cream 33, custard powder 17, egg 43, white sugar 130, toning powder 6, baking powder 7 .

[0080] The small miscellaneous grains are black beans and buckwheat.

[0081] The small miscellaneous grains need to be processed as follows: steam until half-cooked, ultrasonically treated for 12 minutes, dried, and crushed; the ultrasonic power is 130W;

[0082] The pulverization is carried out in a pulverizer, the power of the pulverizer is 160W, 1050r / min, and the time is 11min.

[0083] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com