Plutonium oxalate cup-type continuous precipitation device

A precipitation device, the technology of plutonium oxalate, is applied in the sedimentation tank, carboxylate preparation, carboxylate preparation and other directions, which can solve the problem that the batch precipitation process cannot be continuously fed, the quality of plutonium dioxide products is affected, and the size of precipitated particles is not well controlled. and other problems, to reduce the contamination of the container, improve the aging effect, and prevent the blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

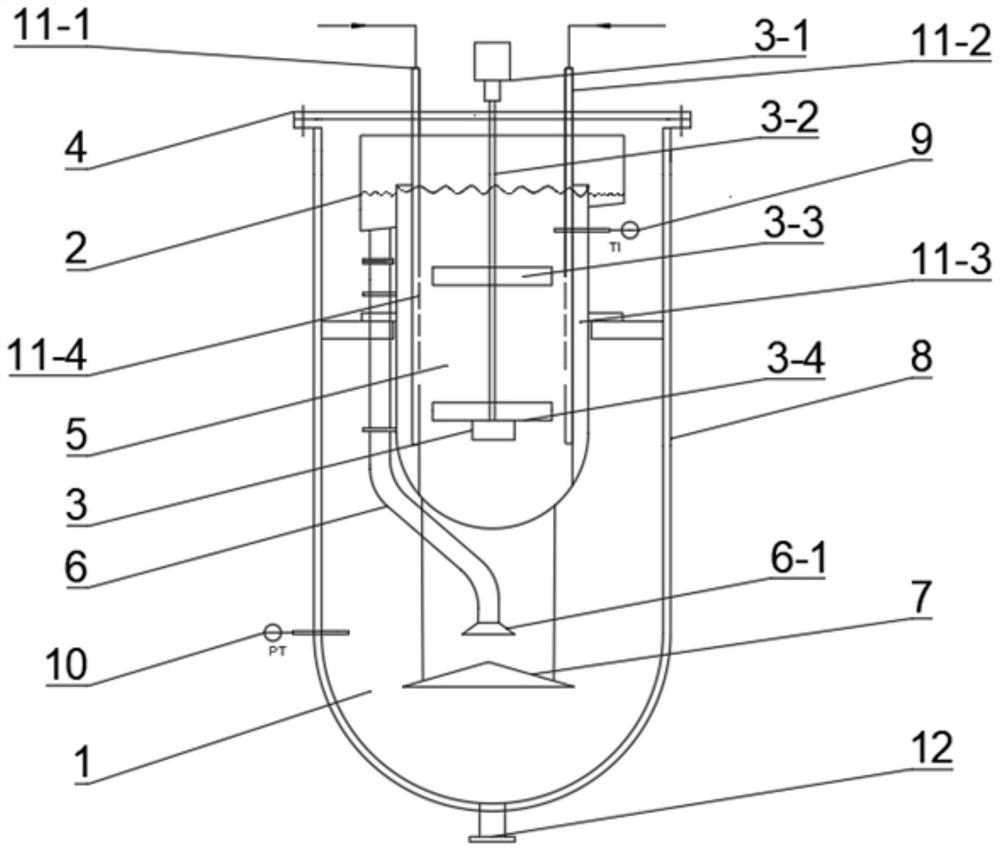

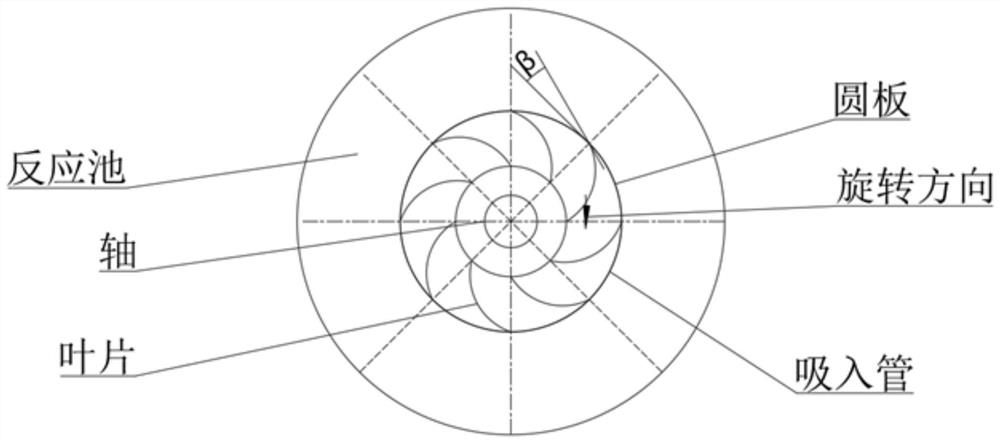

[0023] The technical solution adopted in this specific embodiment is: it includes a sedimentation tank 1, an inclined overflow weir 2, a stirring device 3, a head 4, a reaction tank 5, a sedimentation channel 6, a conical buffer plate 7, a heat preservation jacket 8, Temperature sensor 9, liquid level monitor 10, feed port 11, discharge port 12; stirring device 3 consists of motor 3-1, stirring shaft 3-2, turbine type straight blade stirring paddle 3-3, pump wheel 3- 4 components, wherein the turbine flat-blade stirring paddle 3-3 is connected by the stirring shaft 3-2 above the pump wheel 3-4, and the motor 3-1 drives the operation; the feed port 11 is composed of oxalic acid feed port 11-1 and nitric acid The plutonium feed port 11-2 is formed, and each feed port is provided with a deflector 11-3 and a diversion hole 11-4; the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com