Additive manufacturing device with water-cooling additive manufacturing modules capable of being spliced in stepless sliding manner and additive manufacturing method

A water-cooled, stepless technology, applied in the direction of additive processing, process efficiency improvement, additive manufacturing, etc., can solve the problems of difficult control of forming, device collision, inability to move, etc., to avoid difficult control, ensure rigid fixation, and save substrates material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention will be described in detail below in conjunction with specific embodiments.

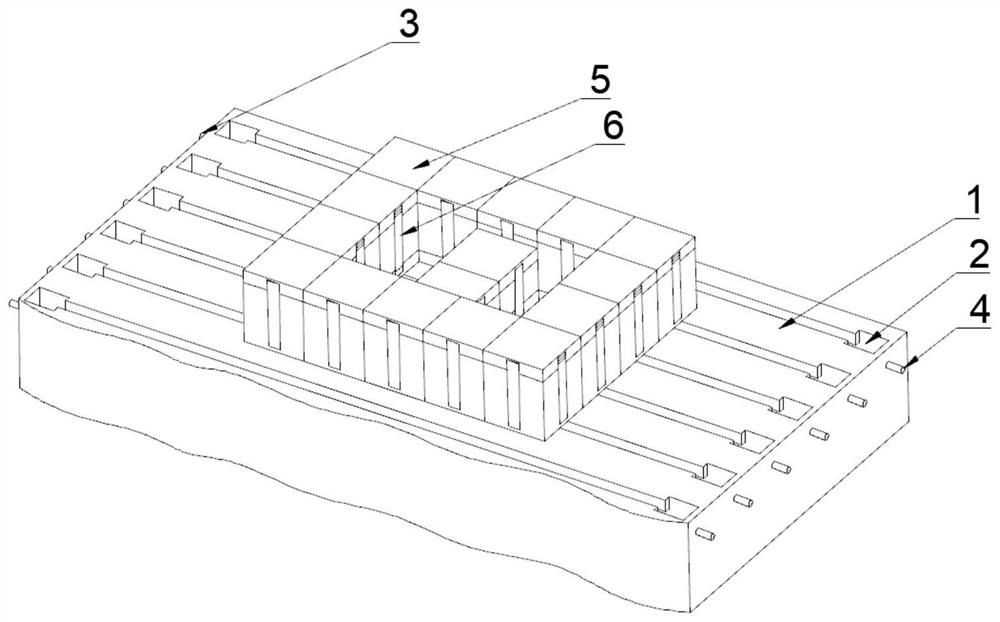

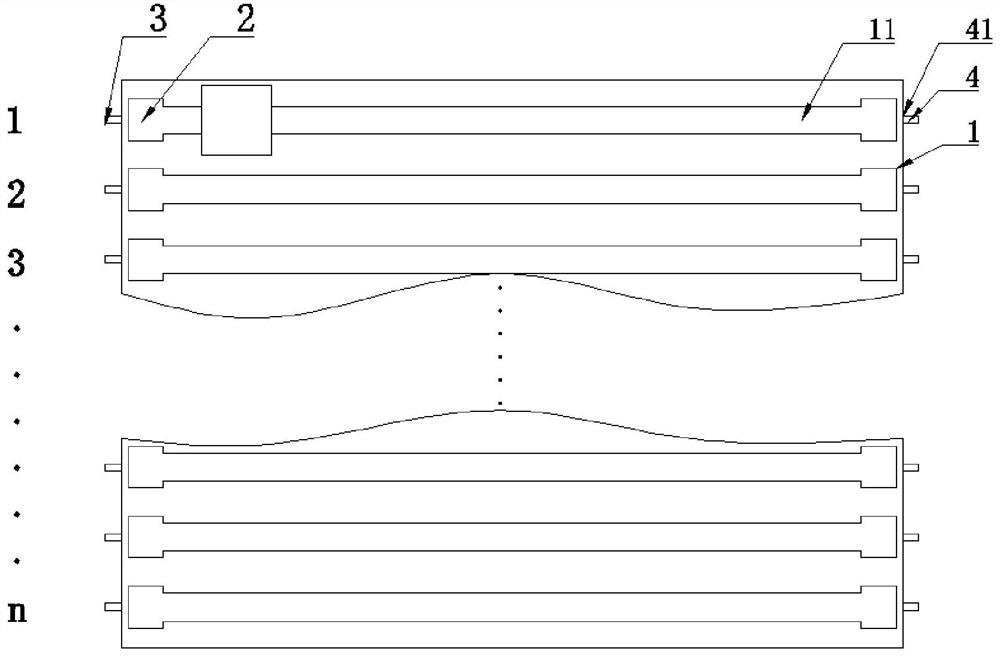

[0032] like Figure 1 to Figure 7 , is an embodiment of the water-cooled additive module that can be spliced by stepless sliding in the present invention, specifically:

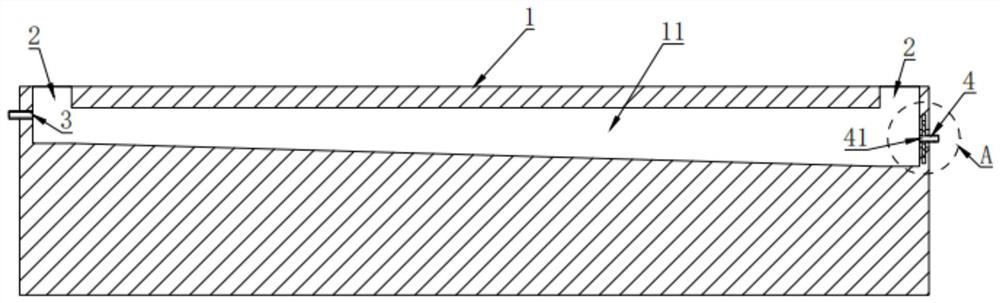

[0033]It includes an additive platform 1, a slider-type water-cooled additive module 8 and a substrate 5; the surface of the additive platform 1 is provided with more than two working areas, and the working areas are strip-shaped, and the edges of adjacent working areas are adjacent to each other. Then, each working area is provided with a chute 11, and the two ends of the chute 11 are respectively provided with a water inlet 3 and a water outlet 41, and the chute 11 is provided with an installation groove 2; the slider type The water-cooled additive module 8 is detachably connected to the installation groove 2, and the slider-type water-cooled additive module 8 is connected or disconnected from the chute 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com